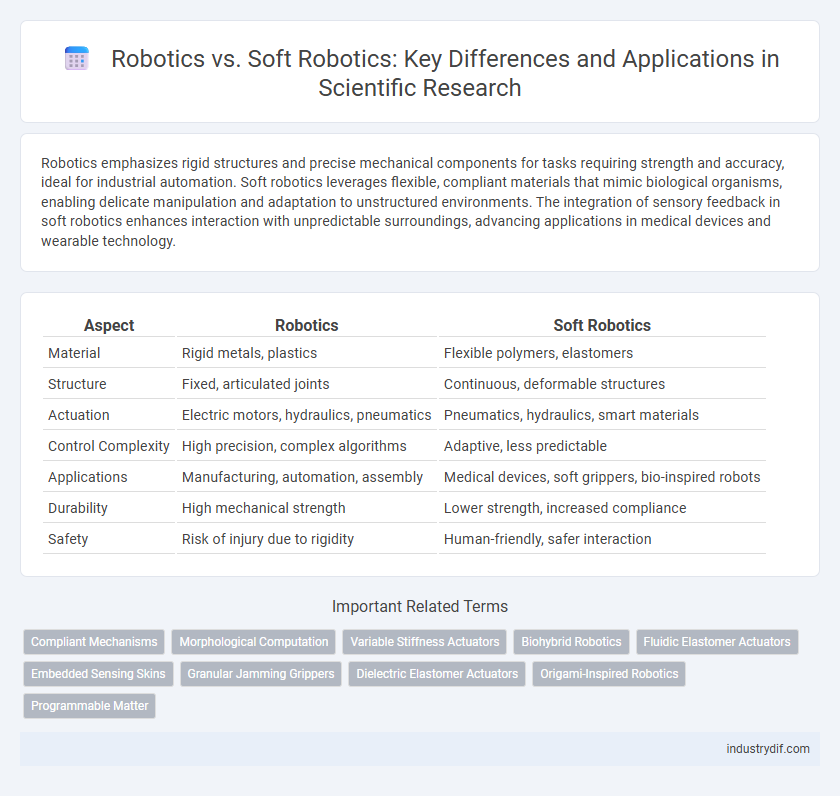

Robotics emphasizes rigid structures and precise mechanical components for tasks requiring strength and accuracy, ideal for industrial automation. Soft robotics leverages flexible, compliant materials that mimic biological organisms, enabling delicate manipulation and adaptation to unstructured environments. The integration of sensory feedback in soft robotics enhances interaction with unpredictable surroundings, advancing applications in medical devices and wearable technology.

Table of Comparison

| Aspect | Robotics | Soft Robotics |

|---|---|---|

| Material | Rigid metals, plastics | Flexible polymers, elastomers |

| Structure | Fixed, articulated joints | Continuous, deformable structures |

| Actuation | Electric motors, hydraulics, pneumatics | Pneumatics, hydraulics, smart materials |

| Control Complexity | High precision, complex algorithms | Adaptive, less predictable |

| Applications | Manufacturing, automation, assembly | Medical devices, soft grippers, bio-inspired robots |

| Durability | High mechanical strength | Lower strength, increased compliance |

| Safety | Risk of injury due to rigidity | Human-friendly, safer interaction |

Defining Robotics and Soft Robotics

Robotics involves the design, construction, and operation of rigid, programmable machines capable of performing complex tasks autonomously or semi-autonomously. Soft robotics utilizes flexible, compliant materials such as silicones and elastomers to create robots that mimic biological organisms' adaptability and dexterity. These soft robots excel in environments requiring safe human interaction, delicate manipulation, and variable shape conformity compared to traditional rigid robotic systems.

Key Differences: Traditional vs Soft Robotics

Traditional robotics primarily relies on rigid components made from metals and hard plastics, enabling precise movements and high-load capacities ideal for industrial automation. Soft robotics utilizes flexible, compliant materials like silicone and elastomers, allowing for adaptive, gentle interactions suited for delicate tasks in biomedical and wearable applications. The key difference lies in material properties, with traditional robots excelling in strength and repeatability while soft robots prioritize flexibility and safe human-robot collaboration.

Core Components and Materials

Robotics relies heavily on rigid components such as metal joints, gears, and actuators made from steel and aluminum alloys, providing precision and durability for repetitive tasks. Soft robotics incorporates flexible materials like silicone, hydrogels, and shape-memory polymers to enable adaptability and safe interaction with unpredictable environments. Core components in soft robotics include pneumatic or hydraulic actuators and embedded sensors that mimic biological systems, enhancing movement versatility compared to traditional rigid robotic structures.

Actuation Mechanisms in Robotics

Traditional robotics predominantly utilizes rigid actuators such as electric motors, hydraulic, and pneumatic systems that provide precise control and high force output for repetitive tasks. Soft robotics employs compliant materials and fluidic or shape-memory alloy actuators, enabling adaptive, flexible movements ideal for delicate manipulation and unpredictable environments. The contrast in actuation mechanisms highlights the trade-off between strength and adaptability, with soft actuators offering enhanced safety and versatility at the expense of load capacity and speed.

Flexibility and Adaptability in Applications

Soft robotics offers superior flexibility and adaptability compared to traditional rigid robotics, enabling safer interaction with delicate objects and complex environments. Materials like silicone and elastomers allow soft robots to deform and conform to diverse shapes, enhancing applications in medical devices, agriculture, and human-robot interaction. Rigid robotics excels in precision and strength but lacks the innate compliance necessary for dynamic and unpredictable tasks, where soft robotics demonstrates distinct advantages.

Safety and Human-Robot Interaction

Soft robotics enhances safety in human-robot interaction by utilizing flexible, compliant materials that reduce the risk of injury during unexpected contact. Conventional rigid robotics, while precise and strong, pose higher risks in collaborative environments due to their inflexible structures and forceful movements. Advances in soft robotics technology enable safer integration in dynamic settings, promoting intuitive and resilient interaction with humans.

Precision and Control Challenges

Robotics traditionally offers high precision and robust control through rigid structures and advanced sensors, enabling exact movements in industrial automation and surgical applications. Soft robotics, composed of flexible, compliant materials, faces challenges in achieving similar levels of precision due to nonlinear deformation and limited actuator accuracy. Advances in bio-inspired designs and real-time feedback control systems aim to improve the precision and control capabilities of soft robots for delicate manipulation tasks.

Current Advancements and Innovations

Recent advancements in robotics emphasize the integration of soft robotics technology to enhance flexibility and adaptability in dynamic environments. Innovations include the development of bio-inspired actuators and multi-material sensors that improve soft robots' dexterity and responsiveness. Current research focuses on leveraging soft materials combined with traditional robotic systems to enable safer human-robot interactions and complex task automation.

Industry Use Cases: Hard vs Soft Robotics

Hard robotics dominate high-precision manufacturing, automotive assembly, and heavy-duty material handling due to their rigidity and strength. Soft robotics excel in delicate tasks like food handling, biomedical applications, and wearable exoskeletons, where flexibility and adaptability reduce damage to soft materials. Industries increasingly integrate both technologies to optimize efficiency, combining hard robots' precision with soft robots' gentle interaction capabilities.

Future Prospects and Emerging Trends

Robotics continues to evolve with advancements in artificial intelligence, sensor technologies, and autonomous systems, enabling more precise, durable, and efficient machines designed for manufacturing, healthcare, and exploration. Soft robotics leverages flexible materials, bio-inspired designs, and novel actuation methods to address challenges in adaptability, safety, and dexterity, opening new possibilities for medical devices, wearable robots, and intricate manipulation tasks. Emerging trends such as hybrid robotic systems, improved material sciences, and machine learning integration will drive a convergence of rigid and soft robotics, expanding capabilities and applications across diverse industries.

Related Important Terms

Compliant Mechanisms

Compliant mechanisms in soft robotics leverage flexible materials to achieve complex motions with fewer parts and enhanced adaptability compared to traditional rigid robotics, which rely on discrete joints and rigid links for movement. This flexibility allows soft robots to perform delicate tasks, navigate unstructured environments, and reduce mechanical wear, advancing applications in biomedical devices and adaptive grippers.

Morphological Computation

Morphological computation in robotics leverages the physical structure of rigid robots to simplify control algorithms by embedding computation into mechanical design, enhancing efficiency and precision in task execution. Soft robotics exploits flexible, deformable materials that naturally perform complex shape transformations and adaptive behaviors, reducing the need for explicit computational control and enabling safer human-robot interactions and complex environmental adaptability.

Variable Stiffness Actuators

Variable stiffness actuators (VSAs) in robotics enable adaptable rigidity control, enhancing precision and safety in dynamic environments, whereas soft robotics inherently rely on compliant materials that provide continuous deformation but lack tunable stiffness. VSAs bridge the gap by combining the robustness of rigid robots with the flexibility of soft robots, offering optimized performance in tasks requiring both strength and adaptability.

Biohybrid Robotics

Biohybrid robotics integrates living biological components with robotic systems, enabling adaptive, flexible, and energy-efficient functionalities that traditional rigid robotics cannot achieve. This fusion enhances soft robotics by incorporating muscle tissues and cellular materials, driving advancements in medical devices, environmental monitoring, and autonomous robotic movement.

Fluidic Elastomer Actuators

Fluidic elastomer actuators in soft robotics offer superior adaptability and compliance compared to traditional rigid robotic systems, enabling safer human-robot interaction and operation in unstructured environments. These actuators utilize pressurized fluids to achieve complex, biomimetic movements that enhance dexterity and flexibility beyond the capabilities of conventional robotic actuators.

Embedded Sensing Skins

Embedded sensing skins in robotics integrate arrays of sensors within robot surfaces to enable precise tactile feedback, structural health monitoring, and adaptive control in rigid systems. In soft robotics, these sensing skins are designed with flexible, stretchable materials allowing complex deformation detection and real-time environmental interaction, enhancing compliance and safety in dynamic tasks.

Granular Jamming Grippers

Granular jamming grippers leverage the transition of granular materials from a fluid-like to a solid-like state by vacuum-induced compaction, enabling soft robotics to achieve adaptive, conformal grasping with high precision and low force. Compared to traditional rigid robotics, these grippers offer enhanced versatility and delicate object manipulation, expanding applications in sensitive environments such as biomedical and agricultural fields.

Dielectric Elastomer Actuators

Dielectric elastomer actuators (DEAs) offer soft robotics enhanced flexibility, lightweight design, and high energy density compared to traditional rigid robotic actuators, enabling more adaptive and biomimetic movements. Unlike conventional robotic components, DEAs utilize electroactive polymers that convert electrical energy into mechanical deformation, facilitating quieter, faster, and more efficient actuation in soft robotic applications.

Origami-Inspired Robotics

Origami-inspired robotics leverages folding techniques to create flexible, lightweight structures enabling complex movements unattainable by traditional rigid robots, enhancing adaptability and functionality in constrained environments. Soft robotics, emphasizing deformable materials, complements this by incorporating compliant elements that improve interaction safety and dexterity, advancing applications in medical devices and wearable technologies.

Programmable Matter

Programmable matter revolutionizes robotics by enabling materials to dynamically change shape and function, offering enhanced adaptability over traditional rigid robotic systems. Soft robotics leverages this technology to create flexible, responsive machines that mimic biological organisms, significantly improving interaction with complex environments.

Robotics vs Soft Robotics Infographic

industrydif.com

industrydif.com