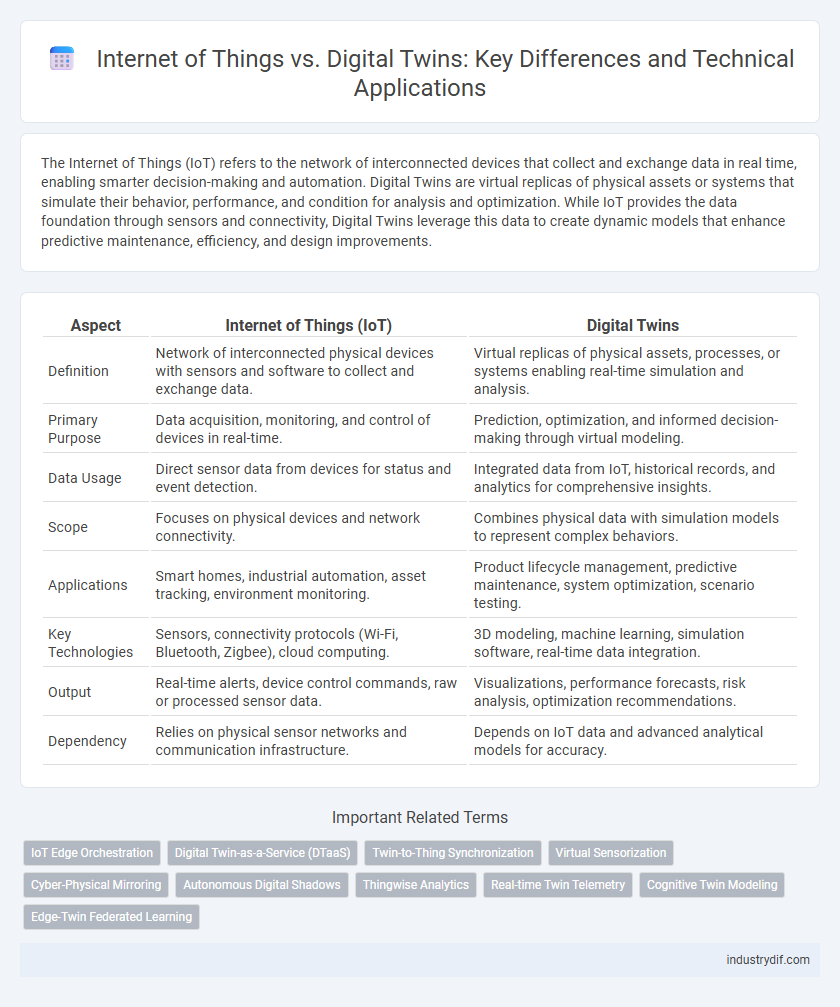

The Internet of Things (IoT) refers to the network of interconnected devices that collect and exchange data in real time, enabling smarter decision-making and automation. Digital Twins are virtual replicas of physical assets or systems that simulate their behavior, performance, and condition for analysis and optimization. While IoT provides the data foundation through sensors and connectivity, Digital Twins leverage this data to create dynamic models that enhance predictive maintenance, efficiency, and design improvements.

Table of Comparison

| Aspect | Internet of Things (IoT) | Digital Twins |

|---|---|---|

| Definition | Network of interconnected physical devices with sensors and software to collect and exchange data. | Virtual replicas of physical assets, processes, or systems enabling real-time simulation and analysis. |

| Primary Purpose | Data acquisition, monitoring, and control of devices in real-time. | Prediction, optimization, and informed decision-making through virtual modeling. |

| Data Usage | Direct sensor data from devices for status and event detection. | Integrated data from IoT, historical records, and analytics for comprehensive insights. |

| Scope | Focuses on physical devices and network connectivity. | Combines physical data with simulation models to represent complex behaviors. |

| Applications | Smart homes, industrial automation, asset tracking, environment monitoring. | Product lifecycle management, predictive maintenance, system optimization, scenario testing. |

| Key Technologies | Sensors, connectivity protocols (Wi-Fi, Bluetooth, Zigbee), cloud computing. | 3D modeling, machine learning, simulation software, real-time data integration. |

| Output | Real-time alerts, device control commands, raw or processed sensor data. | Visualizations, performance forecasts, risk analysis, optimization recommendations. |

| Dependency | Relies on physical sensor networks and communication infrastructure. | Depends on IoT data and advanced analytical models for accuracy. |

Understanding Internet of Things (IoT)

Internet of Things (IoT) refers to a network of interconnected devices and sensors that collect, exchange, and analyze real-time data without human intervention. IoT enables seamless communication between physical objects and digital systems, enhancing automation, monitoring, and decision-making across industries. Key components include embedded sensors, connectivity protocols, cloud computing, and data analytics frameworks essential for scalable IoT deployments.

Defining Digital Twins Technology

Digital Twins technology creates a real-time virtual replica of physical assets, systems, or processes by integrating IoT sensors, data analytics, and simulation tools. This virtual model enables continuous monitoring, predictive maintenance, and performance optimization through synchronized data exchange between the digital and physical entities. Unlike IoT, which primarily collects and transmits data, Digital Twins provide a dynamic, interactive environment for advanced scenario testing and decision-making.

Core Components of IoT Systems

IoT systems consist of core components including sensors, connectivity modules, data processing units, and user interfaces, enabling real-time data collection and communication across devices. Digital twins leverage these IoT components by creating virtual replicas of physical assets, integrating sensor data for simulation, analysis, and optimization in real time. The synergy between IoT's hardware layer and digital twins' software modeling drives efficient monitoring, predictive maintenance, and decision-making in complex systems.

Key Elements of Digital Twin Architecture

Digital Twin architecture centers on three key elements: physical assets, virtual models, and data connectivity, ensuring real-time synchronization between the physical and digital worlds. IoT devices serve as critical data sources, capturing sensor data that feeds into the digital twin for analysis, simulation, and predictive maintenance. The integration of edge computing and cloud platforms enhances scalability and processing power, enabling dynamic interaction and decision-making within the digital twin framework.

Data Acquisition and Real-Time Monitoring

Internet of Things (IoT) leverages a vast network of sensors and devices for continuous data acquisition, enabling real-time monitoring of physical environments. Digital Twins utilize this real-time data to create dynamic, virtual replicas of physical systems, facilitating predictive analytics and simulation-based decision-making. Integration of IoT data into Digital Twins enhances accuracy and responsiveness in operational monitoring and control.

Integration Strategies: IoT and Digital Twins

Integration strategies for Internet of Things (IoT) and Digital Twins emphasize seamless data exchange and real-time synchronization between physical assets and their virtual counterparts. Leveraging IoT sensors enables continuous data collection, which feeds accurate and dynamic models within Digital Twins, enhancing predictive maintenance and operational efficiency. Implementing standardized protocols such as MQTT and OPC UA ensures interoperability, facilitating scalable and secure integration across complex industrial environments.

Applications in Smart Manufacturing

Internet of Things (IoT) enables real-time data collection from connected sensors and devices, facilitating predictive maintenance and process optimization in smart manufacturing. Digital Twins create virtual replicas of physical assets, allowing simulation, performance analysis, and scenario testing to enhance production efficiency and reduce downtime. Together, IoT-driven data and Digital Twin modeling provide comprehensive insights for adaptive manufacturing systems and informed decision-making.

Security Considerations in IoT and Digital Twins

Security considerations in IoT and Digital Twins demand robust encryption protocols and real-time threat detection to protect sensitive data and ensure system integrity. IoT devices often face vulnerabilities due to limited computational resources, making secure firmware updates and network segmentation critical for reducing attack surfaces. Digital Twins require secure synchronization mechanisms and access controls to prevent unauthorized manipulation of virtual models that could compromise physical asset operations.

Scalability and Deployment Challenges

Internet of Things (IoT) solutions often face scalability issues due to the massive data generated by interconnected devices requiring robust network infrastructure and efficient data processing capabilities. Digital Twins demand high computational resources and continuous synchronization with their physical counterparts, complicating deployment in large-scale or resource-constrained environments. Both technologies require tailored integration strategies to address latency, security, and interoperability challenges during widespread implementation.

Future Trends in IoT and Digital Twins Collaboration

Future trends in IoT and Digital Twins collaboration emphasize enhanced real-time data integration and predictive analytics to optimize system performance and maintenance. The convergence of IoT sensor networks with Digital Twin models accelerates autonomous decision-making across smart cities, manufacturing, and healthcare industries. Advances in edge computing and 5G connectivity will further enable seamless synchronization, driving innovation in digital simulation and physical asset management.

Related Important Terms

IoT Edge Orchestration

IoT Edge Orchestration enables seamless management and coordination of distributed Internet of Things devices by processing data locally, reducing latency and bandwidth usage compared to cloud-only architectures. In contrast, Digital Twins leverage real-time IoT Edge data to create dynamic virtual replicas of physical assets, enhancing predictive maintenance and operational efficiency through continuous synchronization.

Digital Twin-as-a-Service (DTaaS)

Digital Twin-as-a-Service (DTaaS) leverages cloud-based platforms to provide scalable, real-time digital replicas of physical assets, enabling enhanced predictive maintenance and system optimization. By integrating IoT sensor data with advanced analytics and AI, DTaaS delivers precise simulations and actionable insights without requiring extensive on-premises infrastructure.

Twin-to-Thing Synchronization

Twin-to-Thing synchronization ensures real-time data exchange between digital twins and their physical IoT counterparts, enabling accurate monitoring, predictive maintenance, and seamless operational efficiency. This bidirectional communication leverages sensor data integration, edge computing, and cloud analytics to maintain consistency and optimize performance across both virtual models and physical assets.

Virtual Sensorization

Virtual sensorization in Digital Twins enables real-time data simulation and monitoring by creating virtual replicas of physical sensors, enhancing predictive maintenance and operational efficiency beyond the traditional Internet of Things (IoT) networks that rely on physical sensor deployments. This approach reduces costs and latency, allowing for more precise analytics and dynamic system adjustments in complex industrial environments.

Cyber-Physical Mirroring

Internet of Things (IoT) enables real-time data collection from interconnected physical devices, while Digital Twins create precise virtual replicas for dynamic simulation and analysis. Cyber-Physical Mirroring leverages IoT data feeds to continuously update Digital Twins, ensuring synchronized interaction between physical assets and their digital counterparts for predictive maintenance and optimized performance.

Autonomous Digital Shadows

Internet of Things (IoT) generates real-time data streams through interconnected sensors and devices, enabling Autonomous Digital Shadows to create dynamic, virtual replicas of physical assets for continuous monitoring and predictive analysis. These digital shadows leverage AI and machine learning algorithms to autonomously adjust and optimize system performance without human intervention, differentiating them from traditional digital twins that often require manual updates.

Thingwise Analytics

Thingwise Analytics leverages Internet of Things (IoT) data streams to create precise Digital Twins, enabling real-time monitoring and predictive maintenance across complex systems. By integrating sensor data with advanced analytics, Thingwise enhances operational efficiency and asset management through dynamic, data-driven simulations.

Real-time Twin Telemetry

Real-time twin telemetry in Digital Twins enables continuous monitoring and precise replication of physical assets by leveraging sensor data collected through Internet of Things (IoT) devices. The integration of IoT with Digital Twins facilitates instantaneous data transmission, analysis, and feedback loops essential for dynamic system optimization and predictive maintenance.

Cognitive Twin Modeling

Cognitive twin modeling enhances Digital Twins by integrating advanced AI algorithms and real-time IoT sensor data to simulate human-like decision-making processes, enabling predictive analytics and autonomous system optimization. Unlike traditional IoT frameworks that primarily collect and transmit data, cognitive twins create dynamic, context-aware digital replicas capable of learning and adapting to environmental changes for improved operational efficiency.

Edge-Twin Federated Learning

Edge-Twin Federated Learning integrates Internet of Things (IoT) devices with Digital Twin technology to enable decentralized data processing and model training at the network edge, reducing latency and enhancing data privacy. This approach leverages edge computing resources to synchronize real-time digital replicas with on-device machine learning, optimizing predictive maintenance and operational efficiency in complex cyber-physical systems.

Internet of Things vs Digital Twins Infographic

industrydif.com

industrydif.com