Supply chain management benefits significantly from digital twin technology by providing real-time simulation and predictive analytics that enhance operational efficiency. Digital twins enable the visualization of entire supply networks, identifying potential disruptions and optimizing logistics strategies before implementation. This integration reduces costs, improves delivery accuracy, and increases overall supply chain resilience.

Table of Comparison

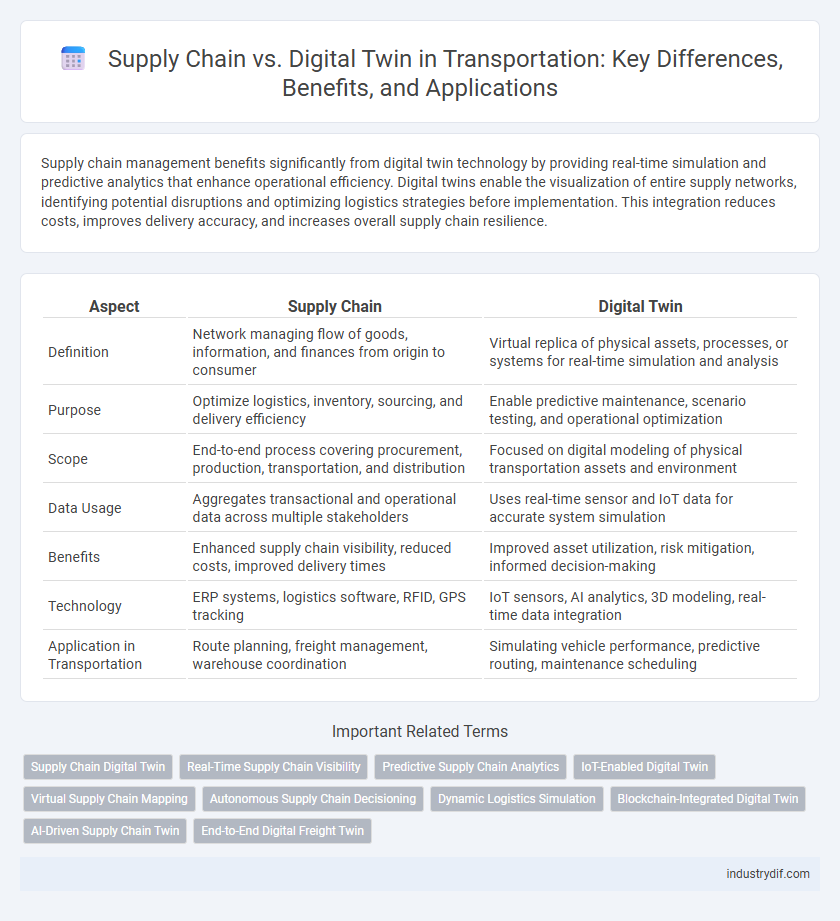

| Aspect | Supply Chain | Digital Twin |

|---|---|---|

| Definition | Network managing flow of goods, information, and finances from origin to consumer | Virtual replica of physical assets, processes, or systems for real-time simulation and analysis |

| Purpose | Optimize logistics, inventory, sourcing, and delivery efficiency | Enable predictive maintenance, scenario testing, and operational optimization |

| Scope | End-to-end process covering procurement, production, transportation, and distribution | Focused on digital modeling of physical transportation assets and environment |

| Data Usage | Aggregates transactional and operational data across multiple stakeholders | Uses real-time sensor and IoT data for accurate system simulation |

| Benefits | Enhanced supply chain visibility, reduced costs, improved delivery times | Improved asset utilization, risk mitigation, informed decision-making |

| Technology | ERP systems, logistics software, RFID, GPS tracking | IoT sensors, AI analytics, 3D modeling, real-time data integration |

| Application in Transportation | Route planning, freight management, warehouse coordination | Simulating vehicle performance, predictive routing, maintenance scheduling |

Understanding Supply Chain in Transportation

Supply chain in transportation involves the systematic coordination of goods movement, inventory management, and logistics operations to ensure timely delivery and cost efficiency. Digital twin technology enhances supply chain visibility by creating virtual replicas of transportation networks, enabling real-time monitoring and predictive analytics. Understanding the interplay between physical supply chains and digital twins optimizes route planning, asset utilization, and risk management in transportation systems.

What is a Digital Twin?

A digital twin is a virtual replica of a physical asset, system, or process used in transportation supply chains to simulate, analyze, and optimize performance in real-time. By integrating IoT sensors and data analytics, digital twins enable enhanced visibility, predictive maintenance, and efficient resource allocation across logistics networks. This technology improves decision-making by providing dynamic insights that mirror actual supply chain operations.

Key Differences: Supply Chain vs Digital Twin

Supply Chain management involves overseeing the flow of goods, information, and resources from suppliers to customers, emphasizing logistics, inventory, and demand forecasting. Digital Twin technology creates a virtual replica of physical supply chain assets, enabling real-time monitoring, simulation, and optimization of processes through data integration and IoT devices. The key difference lies in Supply Chain as a physical operational framework, while Digital Twin serves as an analytical and predictive tool to enhance supply chain efficiency and decision-making.

The Role of Digital Twin in Modern Transportation

Digital Twin technology revolutionizes modern transportation by creating real-time virtual replicas of physical assets, enabling enhanced supply chain visibility and predictive maintenance. By integrating IoT sensors and AI, digital twins optimize route planning, reduce operational costs, and improve asset utilization throughout the supply chain. This dynamic simulation supports proactive decision-making, minimizing delays and enhancing overall transportation efficiency.

Benefits of Integrating Digital Twin with Supply Chains

Integrating digital twins with supply chains enhances real-time visibility and predictive analytics, enabling proactive decision-making and risk management. This integration improves inventory optimization, reduces operational costs, and increases supply chain agility by simulating various scenarios and identifying potential disruptions before they occur. Companies leveraging digital twin technology achieve higher efficiency, improved demand forecasting, and accelerated response times across transportation and logistics networks.

Real-Time Visibility: Supply Chain vs Digital Twin

Real-time visibility in transportation enhances supply chain management by providing dynamic tracking of shipments, inventory levels, and delivery status across multiple transit points. Digital twins elevate this capability by creating virtual replicas of physical assets and logistics processes, allowing for predictive analytics and scenario simulation to optimize routes and reduce delays. Integrating digital twins with supply chain systems results in proactive decision-making and improved operational efficiency through continuous, real-time data synchronization.

Efficiency and Optimization in Transportation

Supply chain management leverages data integration and real-time tracking to optimize transportation routes, minimize delays, and reduce operational costs. Digital twin technology creates virtual replicas of transportation networks, enabling predictive analytics and scenario testing to enhance efficiency and asset utilization. Together, these tools facilitate proactive decision-making, streamline logistics, and improve overall transportation system performance.

Challenges of Implementing Digital Twin Technology

Implementing digital twin technology in transportation supply chains faces challenges such as high data integration complexity, real-time analytics requirements, and significant initial investment costs. Ensuring data accuracy and synchronization between physical assets and their digital counterparts is critical for effective predictive maintenance and operational efficiency. Cybersecurity risks and the need for skilled personnel further complicate the deployment and scaling of digital twin systems.

Future Trends: Digital Twin Transforming Supply Chains

Digital Twin technology is revolutionizing supply chains by enabling real-time simulation and predictive analytics, significantly improving demand forecasting and inventory management. Advanced IoT integration and AI-driven digital replicas allow companies to optimize logistics routes, reduce operational costs, and enhance supply chain resilience. Future trends point to increased adoption of digital twins for end-to-end supply chain transparency, fostering adaptive and agile transportation networks.

Choosing the Right Solution for Your Transportation Needs

Supply chain management and digital twin technology each offer unique advantages for optimizing transportation operations; supply chain solutions provide end-to-end visibility and efficient logistics coordination, while digital twins enable real-time simulation and predictive analytics for infrastructure and vehicle performance. Selecting the right solution depends on your transportation goals--whether prioritizing operational efficiency, cost reduction, or strategic planning--and the complexity of your network. Integrating both technologies can deliver comprehensive insights, driving smarter decision-making and enhancing supply chain resilience in dynamic transportation environments.

Related Important Terms

Supply Chain Digital Twin

Supply Chain Digital Twin technology creates a virtual replica of end-to-end logistics networks, enabling real-time monitoring, predictive analytics, and scenario simulation to optimize transportation efficiency. By integrating IoT sensors, AI algorithms, and big data, this digital representation enhances decision-making, reduces costs, and improves resilience across supply chain operations.

Real-Time Supply Chain Visibility

Real-time supply chain visibility enhances operational efficiency by integrating data from multiple sources, enabling proactive decision-making and risk mitigation. Digital twins simulate supply chain processes in a virtual environment, providing dynamic insights for optimizing logistics, inventory management, and transportation routes.

Predictive Supply Chain Analytics

Predictive supply chain analytics leverages digital twin technology to create real-time, virtual replicas of transportation networks, enabling accurate forecasting of demand, inventory levels, and delivery times. This integration minimizes disruptions, optimizes route planning, and enhances overall supply chain resilience through data-driven decision-making.

IoT-Enabled Digital Twin

IoT-enabled digital twins enhance transportation supply chain management by providing real-time data integration from connected sensors, enabling predictive analytics and proactive maintenance. This digital replication of physical assets optimizes route planning, inventory tracking, and demand forecasting, resulting in increased efficiency and reduced operational costs.

Virtual Supply Chain Mapping

Virtual supply chain mapping leverages digital twin technology to create real-time, dynamic models of transportation networks, enabling precise monitoring and optimization of logistics flows. This integration enhances supply chain visibility by simulating scenarios that predict disruptions and improve decision-making efficiency.

Autonomous Supply Chain Decisioning

Autonomous supply chain decisioning leverages digital twins to create real-time, data-driven simulations that optimize logistics, inventory management, and demand forecasting with enhanced accuracy. Integrating digital twin technology streamlines complex transportation networks by enabling predictive analytics and rapid scenario testing, resulting in more resilient and adaptive supply chains.

Dynamic Logistics Simulation

Supply chain management leverages dynamic logistics simulation through digital twins to enhance real-time decision-making, optimize route planning, and predict disruptions with high accuracy. Digital twin technology integrates live data streams to model transportation networks, enabling precise scenario analysis and adaptive supply chain resilience.

Blockchain-Integrated Digital Twin

Blockchain-integrated digital twins enhance supply chain transparency and traceability by providing immutable real-time data across transportation networks, reducing fraud and improving asset tracking. This convergence optimizes logistics efficiency, enables predictive maintenance, and ensures secure information sharing among all supply chain stakeholders.

AI-Driven Supply Chain Twin

AI-driven supply chain twins leverage advanced machine learning algorithms and real-time data integration to create dynamic, predictive models that optimize logistics, inventory management, and demand forecasting across transportation networks. These digital replicas enhance supply chain resilience by simulating disruptions, enabling proactive decision-making and continuous improvement in delivery efficiency and cost reduction.

End-to-End Digital Freight Twin

End-to-End Digital Freight Twins integrate real-time data from supply chain operations, enabling precise simulation and optimization of transportation routes, asset utilization, and delivery schedules. This digital replication enhances visibility and decision-making across the entire freight ecosystem, reducing delays and operational costs.

Supply Chain vs Digital Twin Infographic

industrydif.com

industrydif.com