Warehouse logistics involves managing large-scale storage, inventory control, and distribution processes to optimize supply chain efficiency. Micro-fulfillment centers focus on rapid order fulfillment within urban areas by utilizing automated systems in smaller spaces to meet e-commerce demand. Choosing between these options depends on factors like delivery speed, inventory turnover, and proximity to customers.

Table of Comparison

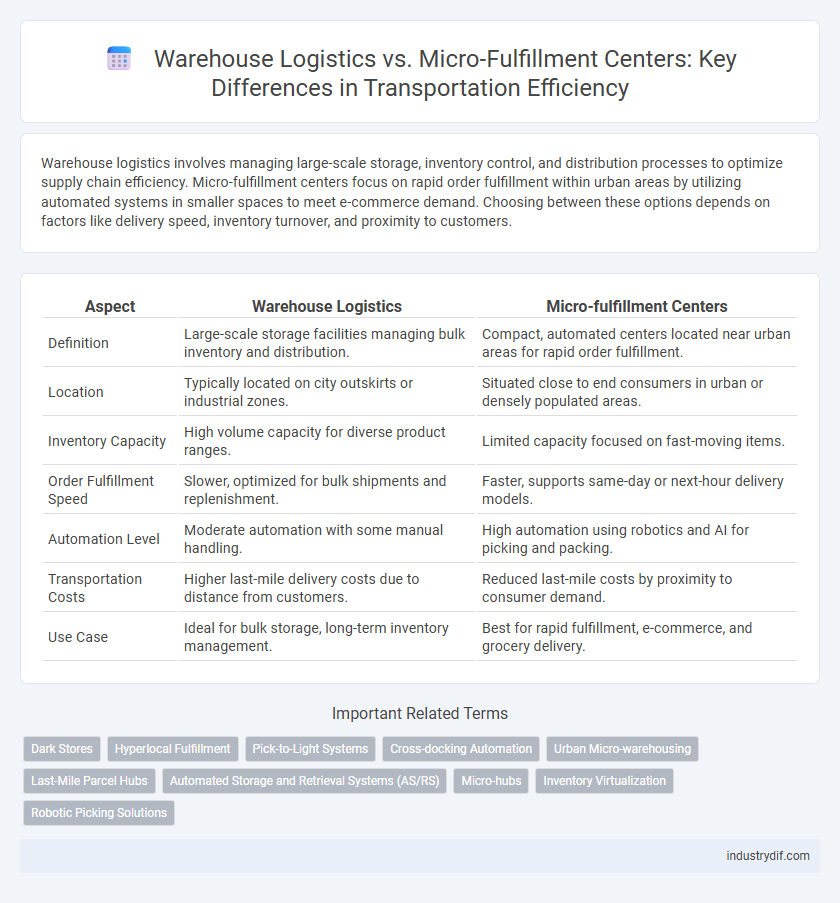

| Aspect | Warehouse Logistics | Micro-fulfillment Centers |

|---|---|---|

| Definition | Large-scale storage facilities managing bulk inventory and distribution. | Compact, automated centers located near urban areas for rapid order fulfillment. |

| Location | Typically located on city outskirts or industrial zones. | Situated close to end consumers in urban or densely populated areas. |

| Inventory Capacity | High volume capacity for diverse product ranges. | Limited capacity focused on fast-moving items. |

| Order Fulfillment Speed | Slower, optimized for bulk shipments and replenishment. | Faster, supports same-day or next-hour delivery models. |

| Automation Level | Moderate automation with some manual handling. | High automation using robotics and AI for picking and packing. |

| Transportation Costs | Higher last-mile delivery costs due to distance from customers. | Reduced last-mile costs by proximity to consumer demand. |

| Use Case | Ideal for bulk storage, long-term inventory management. | Best for rapid fulfillment, e-commerce, and grocery delivery. |

Introduction to Warehouse Logistics and Micro-fulfillment Centers

Warehouse logistics involves the management of large-scale storage facilities designed to handle bulk inventory with efficient inbound and outbound operations utilizing advanced inventory tracking systems and material handling equipment. Micro-fulfillment centers are compact, automated warehouses located closer to urban areas, enabling rapid order processing and last-mile delivery to meet growing e-commerce demand. Both solutions optimize supply chain efficiency but differ significantly in scale, technology deployment, and proximity to end consumers.

Defining Traditional Warehouse Logistics

Traditional warehouse logistics involve managing large storage facilities where goods are received, stored, and dispatched in bulk, supporting long-term inventory management and supply chain efficiency. These warehouses are typically located near transportation hubs to facilitate the movement of goods through freight networks such as trucking, rail, or shipping. The emphasis lies on optimizing space utilization, inventory accuracy, and labor management to handle large volumes with extended processing times.

What Are Micro-fulfillment Centers?

Micro-fulfillment centers are compact, automated warehouses designed to enable rapid order processing and delivery, primarily supporting e-commerce and last-mile distribution. These centers use advanced robotics and AI technology to maximize storage density and optimize picking efficiency within limited urban spaces. By situating near consumer hubs, micro-fulfillment centers reduce delivery times and transportation costs compared to traditional warehouse logistics.

Key Differences Between Warehousing and Micro-fulfillment

Warehouse logistics typically involves large-scale storage facilities designed for bulk inventory management, optimizing space, and long-term stockholding. Micro-fulfillment centers focus on rapid order processing and last-mile delivery efficiency by utilizing smaller, automated facilities situated closer to urban areas. The key differences lie in scale, speed of fulfillment, and proximity to the end consumer, impacting distribution strategies and transportation costs.

Inventory Management in Warehouse Logistics vs Micro-fulfillment

Warehouse logistics relies on bulk inventory storage with centralized management systems that optimize stock levels and reduce replenishment cycles. Micro-fulfillment centers utilize advanced automation and real-time data analytics to manage smaller, high-turnover inventories closer to end consumers. This approach enhances order accuracy and accelerates fulfillment speed compared to traditional warehouse inventory management.

Speed and Efficiency: Comparing Fulfillment Times

Warehouse logistics typically manage large inventory volumes with fulfillment times ranging from 2 to 5 days, optimized for cost-efficiency rather than speed. Micro-fulfillment centers leverage automation and proximity to urban areas, enabling same-day or next-day delivery within hours. Faster order processing and reduced last-mile transit contribute to superior speed and efficiency in micro-fulfillment operations compared to traditional warehouses.

Costs: Investment, Operation, and Scalability

Warehouse logistics typically involve higher initial investment costs due to larger space requirements and extensive infrastructure for storage and handling systems. Operational expenses in warehouse logistics include labor, utilities, and inventory management, which can be substantial but benefit from economies of scale in traditional supply chains. Micro-fulfillment centers offer lower investment and operational costs by leveraging automation and proximity to end customers, enhancing scalability through modular setups that adapt quickly to fluctuating demand.

Technological Innovations in Both Models

Warehouse logistics leverage automated guided vehicles (AGVs) and advanced warehouse management systems (WMS) to optimize large-scale inventory handling and order fulfillment with high accuracy. Micro-fulfillment centers integrate robotics, AI-driven sorting systems, and real-time data analytics to enable rapid, last-mile delivery in urban environments. Both models increasingly adopt IoT sensors and cloud-based platforms to enhance operational efficiency and provide scalable, flexible logistics solutions.

Industry Applications and Suitability

Warehouse logistics excels in handling large-scale inventory storage and managing bulk shipments for industries like manufacturing, wholesale, and retail distribution. Micro-fulfillment centers optimize last-mile delivery and rapid order processing, making them ideal for e-commerce, grocery, and urban retail sectors where speed and proximity to customers are critical. Selecting between traditional warehouses and micro-fulfillment centers depends heavily on factors such as order volume, delivery speed requirements, and geographic service areas.

Future Trends in Warehousing and Micro-fulfillment

Future trends in warehousing and micro-fulfillment emphasize automation and artificial intelligence to enhance inventory accuracy and reduce order processing times. Integration of robotics, Internet of Things (IoT) sensors, and real-time data analytics drives efficiency in both large-scale warehouse logistics and compact micro-fulfillment centers. Sustainability initiatives and renewable energy adoption are increasingly prioritized to minimize the environmental impact of logistics operations.

Related Important Terms

Dark Stores

Dark stores serve as efficient micro-fulfillment centers designed specifically for rapid order processing and last-mile delivery within densely populated urban areas, minimizing delivery times and optimizing inventory management. Unlike traditional warehouse logistics, dark stores are strategically located closer to end customers, leveraging automation and real-time data analytics to enhance order accuracy and operational speed in e-commerce fulfillment.

Hyperlocal Fulfillment

Warehouse logistics traditionally handles bulk storage and distribution over broader regions, while micro-fulfillment centers specialize in hyperlocal fulfillment by processing orders quickly within urban areas to meet same-day delivery demands. Micro-fulfillment centers leverage automation and strategic placement inside cities, drastically reducing last-mile delivery times and improving inventory turnover for e-commerce and retail sectors.

Pick-to-Light Systems

Pick-to-light systems in warehouse logistics enhance efficiency by directing workers to specific storage locations with light signals, reducing picking errors and speeding order fulfillment. Micro-fulfillment centers utilize these systems to optimize space and accelerate last-mile delivery, supporting rapid, high-density order processing in urban environments.

Cross-docking Automation

Cross-docking automation enhances warehouse logistics by streamlining the direct transfer of goods from inbound to outbound transportation, significantly reducing storage time and operational costs. Micro-fulfillment centers leverage automated cross-docking to expedite last-mile delivery, optimizing inventory flow and boosting order accuracy in urban distribution networks.

Urban Micro-warehousing

Urban micro-warehousing streamlines last-mile delivery by positioning inventory closer to densely populated areas, significantly reducing transit times and operational costs compared to traditional warehouse logistics. This shift enhances supply chain agility and responsiveness, meeting growing urban demand through smaller, strategically located fulfillment hubs.

Last-Mile Parcel Hubs

Last-mile parcel hubs in warehouse logistics typically rely on large centralized facilities optimized for bulk storage and longer transit times, whereas micro-fulfillment centers prioritize proximity to urban consumers, enabling faster order processing and delivery. The shift toward micro-fulfillment centers reduces transportation costs and delivery windows by decentralizing inventory closer to end customers.

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) in warehouse logistics optimize inventory management and order fulfillment by using robotic technology to increase storage density and reduce labor costs. In micro-fulfillment centers, AS/RS enables rapid, high-frequency picking for e-commerce, enhancing efficiency in smaller urban spaces through compact, automated solutions.

Micro-hubs

Micro-fulfillment centers (micro-hubs) optimize last-mile delivery by enabling rapid order processing and reducing transportation costs through proximity to urban consumers. Unlike traditional warehouse logistics, these compact facilities leverage automation and real-time inventory management to enhance efficiency in high-demand areas.

Inventory Virtualization

Warehouse logistics relies on centralized inventory management with physical stock stored in large facilities, creating challenges for real-time inventory visibility and responsiveness. Micro-fulfillment centers leverage inventory virtualization through integrated software platforms, enabling seamless allocation and dynamic inventory updates across multiple small-scale locations for faster order fulfillment.

Robotic Picking Solutions

Robotic picking solutions in warehouse logistics enhance order accuracy and efficiency by automating bulk inventory handling across large-scale storage facilities, while micro-fulfillment centers leverage these technologies to expedite last-mile delivery through compact, localized automation. Integration of advanced AI-driven robotic systems in both setups optimizes picking speed and reduces labor costs, supporting the growing demand for rapid e-commerce fulfillment.

Warehouse Logistics vs Micro-fulfillment Centers Infographic

industrydif.com

industrydif.com