Containerization revolutionizes transportation by standardizing cargo sizes, which enhances stacking efficiency and simplifies intermodal transfers. Autonomous container handling leverages robotics and AI to increase operational speed, reduce labor costs, and improve safety within ports. Together, these technologies optimize supply chain logistics, driving faster turnaround times and reduced shipping expenses.

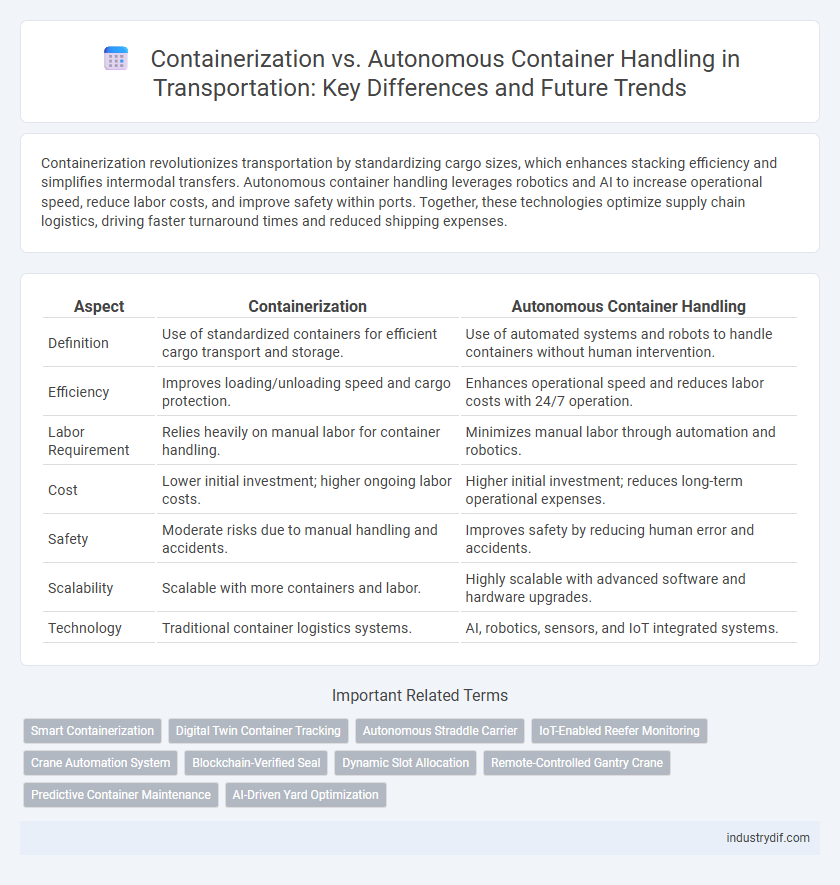

Table of Comparison

| Aspect | Containerization | Autonomous Container Handling |

|---|---|---|

| Definition | Use of standardized containers for efficient cargo transport and storage. | Use of automated systems and robots to handle containers without human intervention. |

| Efficiency | Improves loading/unloading speed and cargo protection. | Enhances operational speed and reduces labor costs with 24/7 operation. |

| Labor Requirement | Relies heavily on manual labor for container handling. | Minimizes manual labor through automation and robotics. |

| Cost | Lower initial investment; higher ongoing labor costs. | Higher initial investment; reduces long-term operational expenses. |

| Safety | Moderate risks due to manual handling and accidents. | Improves safety by reducing human error and accidents. |

| Scalability | Scalable with more containers and labor. | Highly scalable with advanced software and hardware upgrades. |

| Technology | Traditional container logistics systems. | AI, robotics, sensors, and IoT integrated systems. |

Introduction to Containerization in Transportation

Containerization revolutionized transportation by standardizing cargo units, enabling efficient handling, stacking, and transfer across ships, trucks, and trains. This method significantly reduced shipping time, minimized cargo damage, and lowered costs through streamlined logistics and intermodal compatibility. Autonomous container handling introduces advanced robotics and AI to automate loading, unloading, and storage, enhancing precision and operational efficiency in ports and terminals.

Evolution of Container Handling Technologies

Container handling technologies have evolved from traditional manual and crane-based operations to automated systems integrating autonomous vehicles and robotics, significantly increasing efficiency and reducing labor costs. The shift towards autonomous container handling involves AI-driven equipment such as automated guided vehicles (AGVs) and automated stacking cranes (ASCs) that optimize logistics and minimize human error. This progression supports faster turnaround times at ports, enhancing global supply chain reliability and reducing environmental impact through precision and energy-efficient operations.

What is Autonomous Container Handling?

Autonomous container handling refers to the use of automated systems and robotics to manage the loading, unloading, stacking, and transportation of shipping containers within ports and terminals. It integrates technologies such as AI, machine learning, and GPS to optimize container movement, reduce human error, and enhance operational efficiency. This approach minimizes labor costs and downtime while improving safety and throughput in maritime logistics.

Key Benefits of Traditional Containerization

Traditional containerization revolutionized transportation by standardizing cargo sizes, enabling efficient stacking, handling, and intermodal transfers that drastically reduce loading times and damage risks. The widespread adoption of standardized containers facilitates global trade through seamless integration with ships, trucks, and trains, enhancing supply chain reliability. Containerization also lowers transportation costs by optimizing space utilization and minimizing manual labor requirements, driving overall logistical efficiency.

Advantages of Autonomous Container Handling Systems

Autonomous container handling systems improve operational efficiency by reducing human error and enabling 24/7 continuous operation in ports and logistics hubs. These systems enhance safety through precise control and minimized human exposure to hazardous environments, while also optimizing container stacking and retrieval via AI-driven algorithms. Furthermore, they significantly lower labor costs and environmental impact by utilizing electric-powered vehicles and reducing idle times during container transfer processes.

Challenges Faced in Containerization

Containerization faces significant challenges including port congestion, limited infrastructure capacity, and handling inefficiencies that delay cargo movement and increase operational costs. Manual container handling often results in higher labor costs and safety risks, while lack of real-time tracking hinders supply chain visibility and responsiveness. These issues emphasize the need for advanced solutions like autonomous container handling to enhance efficiency and reduce delays in global transportation networks.

Barriers to Autonomous Container Handling Adoption

High initial investment costs and integration complexity create significant barriers to autonomous container handling adoption in the transportation industry. Safety concerns and regulatory compliance issues also slow down implementation, as stringent standards must be met for automation systems. Limited infrastructure compatibility and workforce resistance further challenge seamless deployment of autonomous container handling technologies.

Impact on Operational Efficiency

Containerization streamlines cargo handling by standardizing container sizes and enabling seamless intermodal transfers, significantly reducing loading and unloading times. Autonomous container handling uses AI-driven robotics and automated guided vehicles to optimize port operations, further minimizing human error and operational delays. Together, these technologies enhance throughput, reduce operational costs, and improve supply chain reliability.

Future Trends in Container Handling

Future trends in container handling emphasize the shift from traditional containerization towards autonomous container handling systems powered by artificial intelligence and IoT technologies. These advancements enable enhanced operational efficiency, reduced labor costs, and improved safety through automated cranes, guided vehicles, and real-time tracking. Integration of 5G networks and robotics further accelerates smart port development, promoting seamless, data-driven logistics and supply chain optimization.

Conclusion: The Future of Container Transportation

Containerization revolutionized global trade by standardizing cargo units, drastically improving efficiency and reducing costs in maritime and intermodal transport. Autonomous container handling integrates advanced robotics and AI, promising enhanced precision, safety, and operational speed at ports and terminals. The future of container transportation hinges on widespread adoption of autonomous systems, enabling smarter logistics networks and significantly boosting global supply chain resilience.

Related Important Terms

Smart Containerization

Smart containerization integrates IoT sensors, real-time tracking, and AI-driven analytics to optimize cargo management, reducing delays and enhancing supply chain visibility. Autonomous container handling leverages robotics and automated vehicles for efficient loading and unloading, complementing smart container systems to streamline port operations and minimize human error.

Digital Twin Container Tracking

Digital twin container tracking enhances containerization by creating virtual replicas of physical containers, enabling real-time monitoring and predictive analytics that optimize logistics and reduce operational costs. Autonomous container handling leverages these digital twins to facilitate automated equipment movements, increasing efficiency and minimizing human error in container terminals.

Autonomous Straddle Carrier

Autonomous straddle carriers revolutionize containerization by enabling efficient, driverless container handling in port terminals, reducing labor costs and increasing operational safety. Equipped with advanced sensors and AI, these carriers optimize container stacking and movement, accelerating turnaround times and enhancing overall logistics throughput.

IoT-Enabled Reefer Monitoring

IoT-enabled reefer monitoring enhances containerization by providing real-time temperature, humidity, and location data, ensuring optimal cargo conditions throughout transit. Autonomous container handling integrates this IoT data to automate and optimize loading, unloading, and storage processes, reducing human error and increasing efficiency in supply chain logistics.

Crane Automation System

Containerization revolutionized cargo transport by standardizing container sizes, enabling efficient stacking and handling across ports worldwide. Autonomous container handling, particularly through advanced crane automation systems, enhances operational accuracy and safety while significantly reducing turnaround times in container terminals.

Blockchain-Verified Seal

Blockchain-verified seals enhance containerization by providing immutable records that ensure container integrity and security throughout transit, reducing tampering risks. Autonomous container handling leverages blockchain technology to automate seal verification, enabling real-time, transparent monitoring and seamless trust between stakeholders in the supply chain.

Dynamic Slot Allocation

Dynamic slot allocation in containerization maximizes storage efficiency by optimizing space based on container size, weight, and destination, reducing idle time and improving turnaround. Autonomous container handling integrates AI-driven dynamic slot allocation, enabling real-time adjustments, increased accuracy, and faster container retrieval, enhancing port productivity and reducing operational costs.

Remote-Controlled Gantry Crane

Remote-controlled gantry cranes enhance containerization by enabling precise, efficient loading and unloading without onsite operators, reducing labor costs and increasing safety. Autonomous container handling integrates AI-driven gantry cranes to optimize logistics workflows, minimize human error, and accelerate port throughput.

Predictive Container Maintenance

Predictive container maintenance leverages real-time sensor data and machine learning algorithms to forecast equipment failures and optimize repair schedules, significantly reducing downtime and operational costs. Autonomous container handling systems integrate these predictive analytics to enhance efficiency, safety, and reliability in port logistics by enabling preemptive interventions before maintenance issues escalate.

AI-Driven Yard Optimization

AI-driven yard optimization in autonomous container handling leverages advanced algorithms and real-time data analytics to streamline container placement, reduce handling times, and maximize yard capacity utilization. This contrasts with traditional containerization methods, which rely heavily on manual processes and fixed scheduling, often leading to inefficiencies and increased operational costs.

Containerization vs Autonomous Container Handling Infographic

industrydif.com

industrydif.com