Biodegradable plastics offer an eco-friendly alternative to traditional plastics by breaking down more rapidly under specific conditions, reducing landfill accumulation. PHA-based plastics, derived from microbial fermentation of renewable resources, provide a truly bio-based and compostable solution with strong mechanical properties. Their complete biodegradability in marine and soil environments positions PHA plastics as a promising material for sustainable waste management.

Table of Comparison

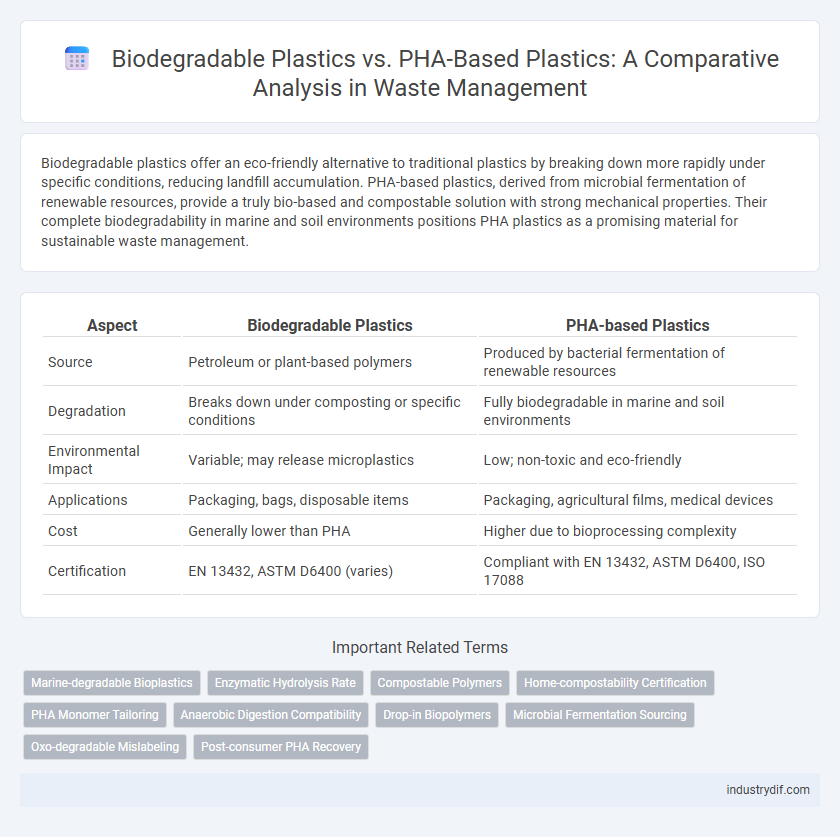

| Aspect | Biodegradable Plastics | PHA-based Plastics |

|---|---|---|

| Source | Petroleum or plant-based polymers | Produced by bacterial fermentation of renewable resources |

| Degradation | Breaks down under composting or specific conditions | Fully biodegradable in marine and soil environments |

| Environmental Impact | Variable; may release microplastics | Low; non-toxic and eco-friendly |

| Applications | Packaging, bags, disposable items | Packaging, agricultural films, medical devices |

| Cost | Generally lower than PHA | Higher due to bioprocessing complexity |

| Certification | EN 13432, ASTM D6400 (varies) | Compliant with EN 13432, ASTM D6400, ISO 17088 |

Overview of Biodegradable Plastics in Waste Management

Biodegradable plastics, including PHA-based plastics, play a critical role in waste management by reducing landfill accumulation and lowering environmental pollution. PHA-based plastics are produced by bacterial fermentation of renewable resources, offering superior biodegradability in marine and soil environments compared to conventional biodegradable plastics. Effective integration of biodegradable plastics in waste management systems enhances organic waste processing and mitigates microplastic contamination.

Understanding PHA-Based Plastics: Definition and Production

PHA-based plastics are biodegradable polymers produced by microbial fermentation of renewable feedstocks such as sugars and lipids. These bioplastics decompose naturally in various environments due to their microbial origin and hydrolyzable ester bonds. Unlike conventional biodegradable plastics, PHAs offer superior biocompatibility and are synthesized through bacterial metabolic pathways, enhancing sustainable waste management solutions.

Degradation Mechanisms: Biodegradable vs. PHA-Based Plastics

Biodegradable plastics primarily degrade through hydrolysis and microbial action, breaking down into water, carbon dioxide, and biomass under specific environmental conditions such as composting. PHA-based plastics, synthesized by microbial fermentation, undergo enzymatic degradation directly by microorganisms in soil and marine environments, resulting in complete mineralization without harmful residues. This enzymatic degradation mechanism renders PHA plastics more efficient and environmentally friendly compared to conventional biodegradable plastics, which may require industrial composting settings.

Feedstock Sources for Biodegradable and PHA Plastics

Biodegradable plastics are primarily derived from renewable feedstocks such as corn starch, sugarcane, and potato starch, which enable their decomposition through microbial activity. PHA-based plastics, or polyhydroxyalkanoates, are produced by bacterial fermentation of organic substrates including agricultural waste, glycerol, and fatty acids, offering a sustainable alternative with a broad range of feedstock flexibility. The use of diverse and renewable feedstock sources not only enhances biodegradability but also reduces reliance on fossil fuels in plastic production.

Environmental Impact Analysis: Lifecycle Assessment

PHA-based plastics exhibit a significantly lower carbon footprint compared to conventional biodegradable plastics due to their microbial production from renewable resources, reducing reliance on fossil fuels. Lifecycle assessments reveal that PHA plastics demonstrate superior biodegradability in marine and soil environments, minimizing long-term pollution and microplastic accumulation. Energy consumption during production and end-of-life degradation phases for PHA plastics is markedly lower, enhancing overall environmental sustainability in waste management systems.

Industrial Compostability and End-of-Life Scenarios

Biodegradable plastics often require specific industrial composting conditions, such as controlled temperature and humidity, to break down effectively, while PHA-based plastics naturally decompose in diverse environments, including marine and soil settings. Industrial compostability certifications like ASTM D6400 and EN 13432 are commonly met by PHA plastics, ensuring they do not leave toxic residues and support circular waste management. End-of-life scenarios for PHA-based plastics include biodegradation without microplastic formation, making them a sustainable alternative to conventional biodegradable plastics that may fragment but persist in landfills or natural ecosystems.

Performance and Application Differences in Packaging

Biodegradable plastics commonly used in packaging, such as polylactic acid (PLA), exhibit moderate barrier properties and require industrial composting conditions for effective breakdown. PHA-based plastics, derived from microbial fermentation, offer superior biodegradability in diverse environments including marine and soil, with comparable mechanical strength and flexibility to conventional plastics. Their enhanced performance in applications like food packaging and single-use items supports sustainable waste management by reducing environmental persistence.

Regulatory Landscape: Standards and Certifications

Biodegradable plastics and PHA-based plastics are subject to evolving regulatory landscapes with specific standards such as ASTM D6400 and EN 13432 that certify compostability and biodegradability. Government agencies worldwide, including the European Commission and the U.S. Environmental Protection Agency (EPA), promote standards ensuring these plastics meet environmental safety and degradation criteria. Certification bodies like TUV Austria and BPI provide verification that PHA-based plastics comply with strict biodegradability timelines and eco-toxicity requirements, enhancing market acceptance and regulatory compliance.

Economic Considerations: Cost and Scalability

Biodegradable plastics generally have lower production costs due to established manufacturing processes, but their scalability is limited by feedstock availability and recycling infrastructure. PHA-based plastics incur higher costs because of expensive microbial fermentation and purification steps, hindering widespread adoption despite superior biodegradability. Economic feasibility depends on technological advancements and market demand to reduce costs and scale production effectively.

Future Trends and Innovations in Bioplastic Waste Solutions

PHA-based plastics demonstrate significant potential for the future of biodegradable plastics due to their complete biodegradability and production from renewable resources like agricultural waste. Innovations in microbial fermentation and genetic engineering are rapidly improving PHA yield and functional properties, making them more cost-competitive and versatile than conventional bioplastics. Emerging waste management technologies, including advanced composting systems and enzymatic recycling, are tailored to optimize the degradation and circularity of PHA-based materials, highlighting their critical role in sustainable waste solutions.

Related Important Terms

Marine-degradable Bioplastics

PHA-based plastics exhibit superior marine biodegradability compared to conventional biodegradable plastics, breaking down efficiently in ocean environments without leaving harmful microplastics. Their natural microbial origin and complete bioassimilation make them a sustainable solution for reducing marine plastic pollution.

Enzymatic Hydrolysis Rate

Biodegradable plastics exhibit variable enzymatic hydrolysis rates, with PHA-based plastics demonstrating superior enzymatic degradation due to their natural polymer structure, enabling faster breakdown by microbial enzymes. This enhanced enzymatic hydrolysis rate of PHA-based plastics significantly reduces environmental persistence compared to conventional biodegradable plastics, promoting more efficient waste management and reduced plastic pollution.

Compostable Polymers

PHA-based plastics are a type of compostable polymer derived from microbial fermentation, offering a fully biodegradable alternative to traditional biodegradable plastics made from petrochemicals. These compostable polymers break down efficiently in industrial composting facilities, reducing landfill waste and lowering environmental impact through carbon sequestration and minimized microplastic formation.

Home-compostability Certification

PHA-based plastics hold a distinct advantage in home-compostability certification due to their natural microbial biodegradation process, allowing them to break down efficiently in typical domestic composting environments. Biodegradable plastics often require industrial composting conditions with controlled temperature and humidity, limiting their home-compostable claims and practical use in residential waste management.

PHA Monomer Tailoring

PHA-based plastics offer superior biodegradability due to precise monomer tailoring, enabling customization of polymer properties such as flexibility, strength, and degradation rate. This molecular-level control contrasts with conventional biodegradable plastics, enhancing environmental performance and expanding applications in packaging and medical fields.

Anaerobic Digestion Compatibility

PHA-based plastics exhibit superior compatibility with anaerobic digestion processes, breaking down efficiently into biogas and biomass within controlled environments. Biodegradable plastics often require specific conditions and may degrade slower under anaerobic digestion, limiting their effectiveness in waste-to-energy systems.

Drop-in Biopolymers

Drop-in biopolymers, such as PHA-based plastics, offer seamless integration into existing plastic manufacturing and recycling systems while providing enhanced biodegradability compared to traditional biodegradable plastics derived from starch or cellulose. PHA-based plastics exhibit superior environmental performance by breaking down naturally in marine and soil environments, reducing microplastic pollution and supporting circular economy goals in waste management.

Microbial Fermentation Sourcing

PHA-based plastics are produced through microbial fermentation of renewable biomass, offering a sustainable alternative to conventional biodegradable plastics derived from petrochemicals or plant-based polymers like PLA; this process harnesses bacteria to convert sugars and lipids into polyhydroxyalkanoates (PHAs), which are fully biodegradable and compostable. Microbial fermentation enables precise control over polymer properties, enhancing biodegradability and reducing environmental impact compared to traditional biodegradable plastics that may persist under certain conditions.

Oxo-degradable Mislabeling

Oxo-degradable plastics are often misclassified as biodegradable, yet they fragment into microplastics rather than fully decomposing, causing long-term environmental harm. PHA-based plastics biodegrade completely through microbial activity, offering a truly sustainable alternative to conventional and oxo-degradable plastics.

Post-consumer PHA Recovery

Post-consumer PHA recovery enhances waste management by facilitating the biodegradable plastic's reintegration into natural cycles, reducing landfill accumulation and microplastic pollution. PHA-based plastics exhibit superior biodegradability and compostability compared to conventional biodegradable plastics, which often require industrial composting facilities for effective decomposition.

Biodegradable Plastics vs PHA-based Plastics Infographic

industrydif.com

industrydif.com