Hazardous waste includes toxic materials from industrial processes that pose significant environmental and health risks if not managed properly. E-waste mining involves extracting valuable metals from discarded electronic devices, reducing the demand for raw mineral mining and minimizing electronic pollution. Properly managing both hazardous waste and e-waste mining contributes to sustainable resource use and environmental protection.

Table of Comparison

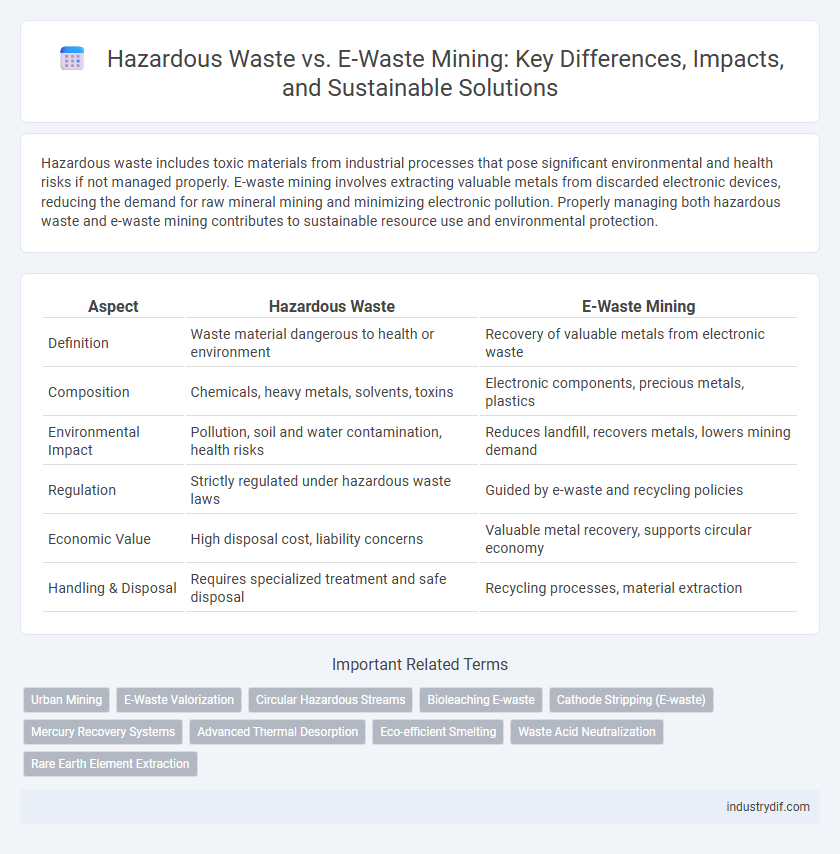

| Aspect | Hazardous Waste | E-Waste Mining |

|---|---|---|

| Definition | Waste material dangerous to health or environment | Recovery of valuable metals from electronic waste |

| Composition | Chemicals, heavy metals, solvents, toxins | Electronic components, precious metals, plastics |

| Environmental Impact | Pollution, soil and water contamination, health risks | Reduces landfill, recovers metals, lowers mining demand |

| Regulation | Strictly regulated under hazardous waste laws | Guided by e-waste and recycling policies |

| Economic Value | High disposal cost, liability concerns | Valuable metal recovery, supports circular economy |

| Handling & Disposal | Requires specialized treatment and safe disposal | Recycling processes, material extraction |

Defining Hazardous Waste and E-Waste Mining

Hazardous waste consists of materials that are dangerous or potentially harmful to human health or the environment, including chemicals, heavy metals, and toxic substances generated from industrial, medical, or household sources. E-waste mining involves extracting valuable metals like gold, silver, and copper from discarded electronic devices, offering a sustainable means to recover resources while reducing electronic pollution. Understanding hazardous waste versus e-waste mining highlights the environmental risks of improper disposal and the opportunities for resource recovery through advanced recycling technologies.

Key Differences Between Hazardous Waste and E-Waste

Hazardous waste encompasses materials that pose significant risks to human health or the environment due to their toxic, corrosive, or reactive properties, while e-waste specifically refers to discarded electronic devices containing hazardous substances like lead, mercury, and cadmium. The mining process for e-waste involves recovering valuable metals such as gold, silver, and copper through specialized recycling techniques, whereas hazardous waste disposal requires strict regulatory compliance to prevent contamination and ensure safe handling. Unlike hazardous waste, e-waste mining emphasizes resource recovery and material reuse, addressing both environmental pollution and raw material scarcity.

Sources and Types of Hazardous Waste

Hazardous waste from e-waste mining primarily includes heavy metals such as lead, mercury, cadmium, and arsenic, which originate from discarded electronic devices like batteries, circuit boards, and cathode ray tubes. This type of waste is characterized by its toxic, flammable, corrosive, or reactive properties, posing significant environmental and health risks during improper disposal or processing. Common sources also involve industrial activities related to the extraction and recovery of valuable metals, where chemical solvents and acidic residues contribute to hazardous waste streams.

The Evolution of E-Waste Mining

E-waste mining has evolved as an innovative approach to recover valuable metals like gold, silver, and copper from discarded electronics, reducing reliance on hazardous waste disposal. Unlike traditional hazardous waste treatment, e-waste mining targets resource extraction from electronic scrap, minimizing environmental pollution and promoting circular economy practices. Advances in automation and chemical processing have enhanced efficiency, making e-waste a critical urban mine for sustainable resource management.

Environmental Impacts of Hazardous Waste

Hazardous waste from mining, including toxic chemicals and heavy metals, significantly contaminates soil and groundwater, posing severe risks to ecosystems and human health. Unlike e-waste, which primarily involves electronic components, hazardous mining waste generates persistent pollutants that bioaccumulate and disrupt local biodiversity. Effective management and remediation strategies are crucial to mitigate long-term environmental degradation caused by hazardous waste mining activities.

Risks and Rewards of E-Waste Mining

E-waste mining recovers valuable metals like gold, silver, and copper from discarded electronics, reducing reliance on hazardous waste landfills and conserving natural resources. While it poses risks such as exposure to toxic substances like lead and mercury, proper recycling technologies mitigate health hazards and environmental contamination. The rewards include sustainable resource management, economic benefits from material recovery, and decreased environmental impact compared to traditional hazardous waste disposal methods.

Regulatory Frameworks: Handling Hazardous Waste vs E-Waste

Regulatory frameworks for hazardous waste and e-waste mining differ significantly, with hazardous waste governed by strict laws like the Resource Conservation and Recovery Act (RCRA) in the U.S., emphasizing containment, treatment, and disposal to prevent environmental contamination. E-waste mining is increasingly regulated through directives such as the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, which mandates the responsible collection, recycling, and recovery of valuable metals while minimizing toxic byproducts. Compliance with these frameworks ensures safer handling, reduces environmental risks, and promotes sustainable resource recovery practices in both hazardous waste and e-waste mining sectors.

Innovative Technologies in Hazardous Waste Management

Innovative technologies in hazardous waste management, such as advanced bioremediation and plasma gasification, significantly reduce environmental impact by efficiently treating toxic substances often found in e-waste mining sites. These technologies enable safer extraction and recycling of valuable metals like gold and rare earth elements, minimizing hazardous residues. Implementing smart sensor networks and AI-driven sorting systems enhances the precision and safety of hazardous waste processing, promoting sustainable waste management practices.

Sustainable Solutions in E-Waste Mining

Sustainable solutions in e-waste mining prioritize the recovery of valuable metals such as gold, silver, and rare earth elements while minimizing environmental contamination from hazardous waste chemicals like lead and mercury. Advanced techniques like bioleaching and automated sorting increase resource efficiency and reduce the release of toxic substances commonly associated with traditional hazardous waste management. Integrating circular economy principles, e-waste mining supports resource conservation and pollution reduction compared to conventional hazardous waste disposal methods.

Future Trends: Integrating Circular Economy in Waste Industries

Future trends in hazardous waste and e-waste mining prioritize circular economy integration to maximize resource recovery and minimize environmental impact. Advanced technologies enable efficient extraction of critical metals from e-waste and hazardous residues, supporting sustainable supply chains for electronics and industrial materials. Policy frameworks increasingly enforce extended producer responsibility and promote recycling infrastructure expansion to drive closed-loop waste management systems.

Related Important Terms

Urban Mining

Urban mining efficiently recovers valuable metals such as gold, silver, and rare earth elements from e-waste, reducing reliance on hazardous waste landfills and traditional mining methods. This sustainable approach mitigates environmental risks by minimizing toxic chemical leachates and heavy metal contamination inherent in hazardous waste disposal.

E-Waste Valorization

E-waste valorization involves extracting valuable metals like gold, silver, and copper from discarded electronic devices, significantly reducing hazardous waste accumulation and environmental contamination. This sustainable mining approach not only mitigates the negative impacts of hazardous waste but also supports resource recovery and circular economy principles by turning electronic waste into profitable raw materials.

Circular Hazardous Streams

Circular hazardous streams prioritize the safe recovery and reuse of toxic materials from hazardous waste and e-waste mining processes to minimize environmental impact. Efficient extraction of valuable metals like lead, mercury, and cadmium from e-waste supports sustainable resource management and reduces the need for virgin resource mining.

Bioleaching E-waste

Bioleaching of e-waste leverages microorganisms to extract valuable metals like gold, copper, and nickel from electronic components, offering a sustainable alternative to hazardous waste mining that often releases toxic substances such as lead, mercury, and cadmium into the environment. This biotechnological approach reduces environmental pollution and enhances metal recovery efficiency compared to conventional methods.

Cathode Stripping (E-waste)

Cathode stripping in e-waste mining involves selectively removing valuable metals like copper, gold, and silver from cathode ray tubes and printed circuit boards, reducing hazardous waste generation compared to traditional hazardous waste disposal methods. Efficient cathode stripping minimizes toxic chemical leaching and promotes resource recovery, making it a critical process in sustainable electronic waste management and hazardous material mitigation.

Mercury Recovery Systems

Mercury recovery systems play a crucial role in hazardous waste management, efficiently extracting mercury from contaminated materials to prevent environmental contamination and health risks. In contrast, e-waste mining primarily targets valuable metals like gold and copper, with mercury recovery being a specialized process within hazardous waste treatment to address toxic element hazards.

Advanced Thermal Desorption

Advanced Thermal Desorption technology efficiently separates hazardous waste contaminants from e-waste mining residues by heating materials to volatilize toxic compounds without combustion, enabling safer recovery of valuable metals like gold, silver, and palladium. This method significantly reduces environmental pollution and enhances metal extraction efficiency compared to traditional hazardous waste treatment processes.

Eco-efficient Smelting

Eco-efficient smelting techniques in hazardous waste and e-waste mining significantly reduce environmental impact by lowering energy consumption and minimizing toxic emissions such as heavy metals and dioxins. Advanced metallurgical processes enhance the recovery rates of valuable metals like gold, copper, and rare earth elements while ensuring compliance with stringent environmental regulations.

Waste Acid Neutralization

Waste acid neutralization is a critical process in hazardous waste and e-waste mining to prevent environmental contamination from toxic substances like heavy metals and acid residues. Implementing effective neutralization techniques, such as using alkaline compounds to stabilize waste acids, reduces hazardous waste risks and enables safer recycling of valuable materials from electronic components.

Rare Earth Element Extraction

Hazardous waste from rare earth element extraction in e-waste mining poses significant environmental risks due to toxic chemicals like heavy metals and acids used in processing. Efficient recycling methods targeting rare earth elements reduce reliance on traditional mining, minimizing hazardous waste generation and conserving finite natural resources.

Hazardous Waste vs E-waste Mining Infographic

industrydif.com

industrydif.com