Residual waste refers to the non-recyclable and non-compostable materials left after sorting, typically destined for landfills or incineration without energy recovery. Refuse-derived fuel (RDF) is produced by processing residual waste to remove recyclables and moisture, creating a combustible material used as an alternative energy source in industrial plants. RDF reduces landfill volume and generates energy, offering an environmentally preferable solution to managing residual waste.

Table of Comparison

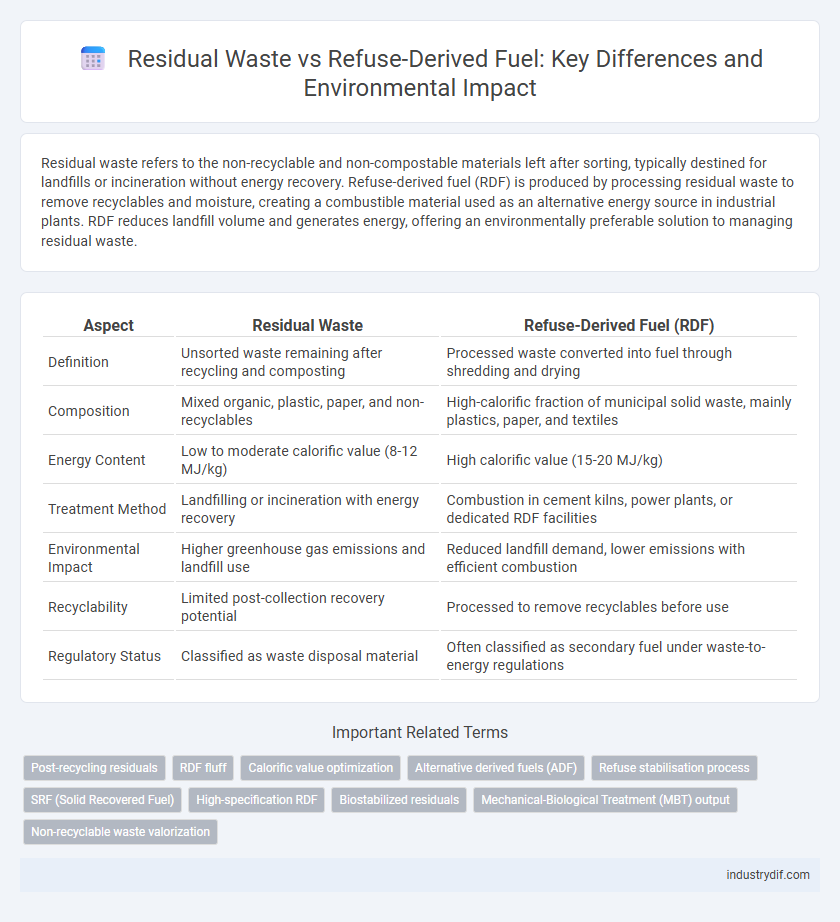

| Aspect | Residual Waste | Refuse-Derived Fuel (RDF) |

|---|---|---|

| Definition | Unsorted waste remaining after recycling and composting | Processed waste converted into fuel through shredding and drying |

| Composition | Mixed organic, plastic, paper, and non-recyclables | High-calorific fraction of municipal solid waste, mainly plastics, paper, and textiles |

| Energy Content | Low to moderate calorific value (8-12 MJ/kg) | High calorific value (15-20 MJ/kg) |

| Treatment Method | Landfilling or incineration with energy recovery | Combustion in cement kilns, power plants, or dedicated RDF facilities |

| Environmental Impact | Higher greenhouse gas emissions and landfill use | Reduced landfill demand, lower emissions with efficient combustion |

| Recyclability | Limited post-collection recovery potential | Processed to remove recyclables before use |

| Regulatory Status | Classified as waste disposal material | Often classified as secondary fuel under waste-to-energy regulations |

Defining Residual Waste

Residual waste refers to the portion of municipal solid waste that remains after recyclable materials and organic waste have been separated for recovery or composting. It generally includes non-recyclable plastics, contaminated materials, and certain household wastes that cannot be processed further for reuse. Unlike refuse-derived fuel, residual waste is typically destined for landfill or incineration without energy recovery.

Understanding Refuse-Derived Fuel (RDF)

Refuse-Derived Fuel (RDF) is a processed form of residual waste consisting primarily of combustible materials such as plastics, paper, and textiles, which are separated and treated to enhance energy recovery. RDF provides a sustainable alternative to landfilling by converting non-recyclable waste into fuel for energy production, reducing environmental impact. This fuel is commonly used in cement kilns and power plants to lower reliance on fossil fuels and decrease greenhouse gas emissions.

Composition Differences: Residual Waste vs RDF

Residual waste primarily consists of mixed household and commercial solid waste, including organic matter, plastics, paper, and non-recyclable materials that remain after recycling efforts. Refuse-Derived Fuel (RDF) is composed mainly of combustible materials such as plastics, textiles, paper, and wood, with a significantly reduced organic content due to preprocessing and sorting. The higher calorific value of RDF results from the removal of non-combustible and wet components, distinguishing its composition sharply from heterogeneous residual waste.

Processing Methods for Residual Waste

Residual waste is often processed through mechanical-biological treatment (MBT), involving mechanical sorting to separate recyclables followed by biological stabilization to reduce organic content. Thermal techniques such as incineration with energy recovery also serve as common methods, converting residual waste into heat or electricity while minimizing landfill use. The processing efficiency depends on waste composition, moisture content, and technology applied, influencing both environmental impact and resource recovery potential.

RDF Production: Conversion and Treatment

Residual waste undergoes mechanical and biological treatment to separate recyclable materials and organic content before RDF production. The conversion process involves shredding, drying, and homogenizing waste to produce Refuse-Derived Fuel with a consistent calorific value suitable for energy recovery. Treatment technologies such as magnetic separation and air classification enhance RDF quality by removing contaminants and improving fuel composition.

Environmental Impact Comparison

Residual waste often ends up in landfills, contributing to methane emissions and long-term soil contamination, whereas refuse-derived fuel (RDF) converts waste materials into energy, reducing landfill volume and lowering greenhouse gas emissions. RDF combustion emits fewer pollutants compared to traditional fossil fuels, enhancing air quality and supporting sustainable energy goals. Lifecycle analyses show that RDF's environmental benefits hinge on efficient processing and emission controls to minimize toxic byproducts.

Energy Recovery from Residual Waste and RDF

Energy recovery from residual waste involves extracting usable energy through processes such as incineration or gasification, reducing landfill volume and generating electricity or heat. Refuse-Derived Fuel (RDF) is produced by processing residual waste to remove recyclables and non-combustibles, resulting in a fuel with higher calorific value used in industrial power plants and cement kilns. Utilizing RDF enhances waste-to-energy efficiency by providing a consistent and cleaner fuel source compared to untreated residual waste.

Regulatory Standards and Compliance

Residual waste is subject to strict regulatory standards such as the EU Waste Framework Directive and U.S. EPA guidelines, emphasizing landfill reduction and environmental protection. Refuse-derived fuel (RDF) must comply with specific emission limits under air quality regulations like the Industrial Emissions Directive (IED) and ASTM standards to ensure safe combustion. Compliance with these frameworks is critical for waste management facilities to minimize environmental impact and meet sustainability goals.

Economic Factors in Residual Waste vs RDF

Residual waste management incurs higher disposal costs due to landfill taxes and transportation expenses, whereas refuse-derived fuel (RDF) generates revenue through energy recovery and reduces landfill reliance. The economic viability of RDF improves with rising fossil fuel prices and government incentives for renewable energy production. Investment in RDF processing infrastructure presents upfront capital challenges but offers long-term savings by diverting waste from costly landfill sites.

Future Trends in Waste Management and RDF

Future trends in waste management emphasize the increasing adoption of refuse-derived fuel (RDF) as a sustainable alternative to traditional residual waste disposal. Advanced technologies in RDF production enhance energy recovery while reducing landfill dependence and greenhouse gas emissions. Emerging policies incentivize RDF integration into circular economy frameworks, promoting resource efficiency and minimizing environmental impact.

Related Important Terms

Post-recycling residuals

Post-recycling residual waste primarily consists of non-recyclable materials left after the extraction of recyclable content, often characterized by reduced organic matter and increased moisture content. Refuse-Derived Fuel (RDF) processes these residuals by converting them into a high-energy substitute fuel, enhancing waste-to-energy efficiency while minimizing landfill dependency.

RDF fluff

Residual waste consists of mixed garbage left after recyclable materials are removed, often leading to higher landfill usage and environmental impact. Refuse-Derived Fuel (RDF) fluff is the lightweight, low-density fraction separated during RDF production, typically composed of paper, plastics, and textiles, which can be processed into alternative fuel sources for energy recovery.

Calorific value optimization

Residual waste typically has a lower calorific value due to its heterogeneous composition, reducing energy recovery efficiency. Refuse-derived fuel (RDF) enhances calorific value by selectively processing combustible materials, optimizing fuel quality for waste-to-energy conversion.

Alternative derived fuels (ADF)

Residual waste consists primarily of non-recyclable municipal solid waste, while refuse-derived fuel (RDF) is processed waste material optimized for energy recovery through combustion. Alternative Derived Fuels (ADF) encompass specialized fuels like RDF and solid recovered fuels (SRF), designed to reduce landfill dependency by converting residual waste into high-calorific energy sources for industrial use.

Refuse stabilisation process

Refuse-Derived Fuel (RDF) undergoes a refuse stabilization process that reduces organic content and moisture, enhancing its combustion efficiency and lowering emissions compared to residual waste. This stabilization converts heterogeneous waste into a more uniform, energy-rich fuel, optimizing thermal recovery and minimizing landfill dependency.

SRF (Solid Recovered Fuel)

Solid Recovered Fuel (SRF) is a high-quality form of refuse-derived fuel (RDF) produced from residual waste through advanced sorting and processing techniques, resulting in a more homogeneous and energy-dense fuel. SRF offers improved combustion efficiency and lower emissions compared to untreated residual waste, making it a sustainable alternative for energy recovery in waste-to-energy plants.

High-specification RDF

High-specification refuse-derived fuel (RDF) is produced by processing residual waste to remove contaminants and enhance fuel quality, resulting in a consistent calorific value suitable for energy recovery in advanced combustion plants. This refined RDF offers improved emissions performance and operational efficiency compared to untreated residual waste, supporting sustainable waste-to-energy solutions.

Biostabilized residuals

Biostabilized residuals from residual waste treatment exhibit reduced biodegradability and odor, making them more suitable for safe landfill disposal compared to refuse-derived fuel, which is processed for energy recovery through combustion. This stabilization process lowers the environmental impact by minimizing leachate production and methane emissions, positioning biostabilized residuals as an effective waste management solution within integrated waste systems.

Mechanical-Biological Treatment (MBT) output

Mechanical-Biological Treatment (MBT) processes residual waste to produce a stabilized organic fraction and a refuse-derived fuel (RDF) with enhanced calorific value, optimizing energy recovery. MBT output reduces landfill volumes by transforming mixed residual waste into RDF for incineration and compost-like material for land application, aligning with circular economy goals.

Non-recyclable waste valorization

Residual waste consists of non-recyclable materials that cannot be processed through conventional recycling methods, while refuse-derived fuel (RDF) transforms this waste into a valuable energy source through mechanical and thermal treatments. RDF valorizes non-recyclable waste by converting it into combustible pellets or flakes used in industrial energy recovery, significantly reducing landfill dependency and greenhouse gas emissions.

Residual Waste vs Refuse-Derived Fuel Infographic

industrydif.com

industrydif.com