Solid waste management involves the collection, treatment, and disposal of non-hazardous waste materials generated by households, businesses, and institutions, aiming to minimize environmental impact. Industrial symbiosis promotes resource efficiency by facilitating the exchange of materials, energy, and by-products between industrial processes, reducing solid waste generation and lowering overall environmental footprints. This collaborative approach transforms waste streams into valuable inputs, advancing sustainable production and waste reduction goals.

Table of Comparison

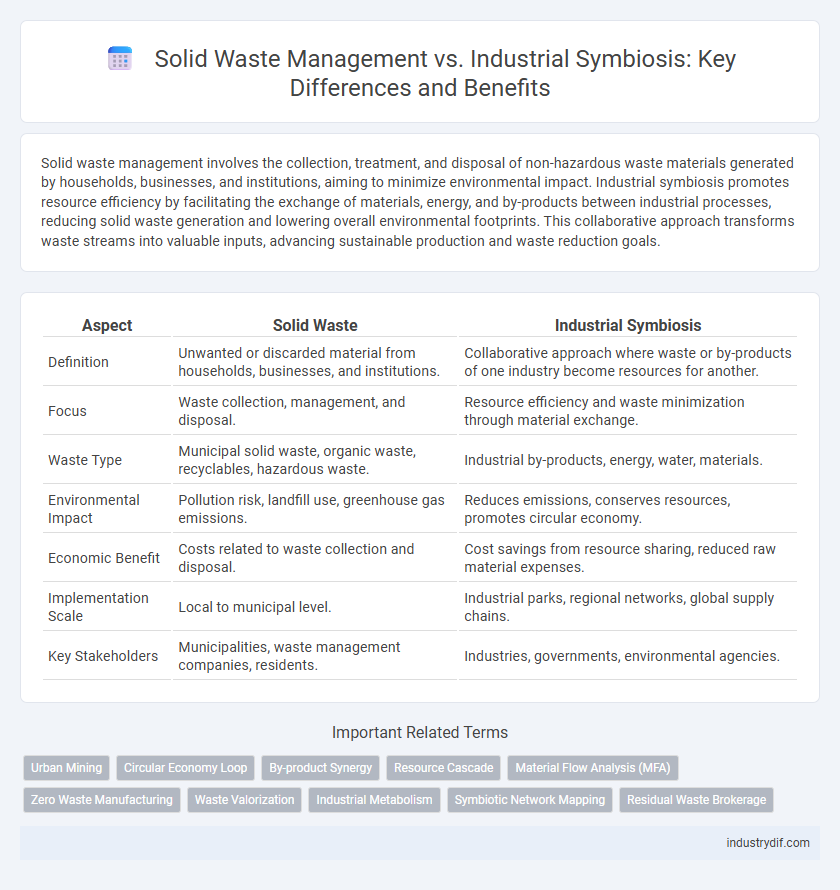

| Aspect | Solid Waste | Industrial Symbiosis |

|---|---|---|

| Definition | Unwanted or discarded material from households, businesses, and institutions. | Collaborative approach where waste or by-products of one industry become resources for another. |

| Focus | Waste collection, management, and disposal. | Resource efficiency and waste minimization through material exchange. |

| Waste Type | Municipal solid waste, organic waste, recyclables, hazardous waste. | Industrial by-products, energy, water, materials. |

| Environmental Impact | Pollution risk, landfill use, greenhouse gas emissions. | Reduces emissions, conserves resources, promotes circular economy. |

| Economic Benefit | Costs related to waste collection and disposal. | Cost savings from resource sharing, reduced raw material expenses. |

| Implementation Scale | Local to municipal level. | Industrial parks, regional networks, global supply chains. |

| Key Stakeholders | Municipalities, waste management companies, residents. | Industries, governments, environmental agencies. |

Defining Solid Waste: Industry Perspectives

Solid waste refers to non-liquid, discarded materials generated from industrial, commercial, and residential activities, encompassing a wide range of items such as packaging, food scraps, and manufacturing byproducts. From an industry perspective, managing solid waste effectively involves strategies to reduce landfill use, improve recycling rates, and repurpose materials to enhance sustainability. Industrial symbiosis leverages solid waste by turning byproducts from one facility into valuable inputs for another, promoting resource efficiency and reducing overall environmental impact.

Understanding Industrial Symbiosis in Modern Manufacturing

Industrial symbiosis transforms solid waste management in modern manufacturing by enabling companies to exchange by-products, turning waste into valuable resources. This approach reduces landfill dependency and minimizes environmental impact while promoting cost savings through resource efficiency. Implementing industrial symbiosis enhances sustainability by aligning waste streams with industrial processes, fostering circular economy principles.

Key Differences: Solid Waste Management vs Symbiotic Practices

Solid waste management primarily involves the collection, treatment, and disposal of non-hazardous waste from households and businesses to reduce environmental impact. Industrial symbiosis emphasizes resource efficiency by facilitating the exchange of materials, energy, and by-products between industries, creating closed-loop systems that minimize waste generation. While solid waste management addresses waste disposal challenges, industrial symbiosis focuses on collaborative practices that transform waste into valuable inputs, promoting sustainability.

Environmental Impacts: Comparing Solid Waste and Symbiosis

Solid waste management often leads to significant environmental impacts such as landfill methane emissions, soil contamination, and groundwater pollution due to improper disposal methods. In contrast, industrial symbiosis reduces environmental footprints by promoting resource efficiency, minimizing waste generation, and enabling the reuse of by-products across industries. This approach significantly lowers greenhouse gas emissions and conserves natural resources, contributing to sustainable waste reduction.

Economic Benefits of Industrial Symbiosis Over Traditional Waste Disposal

Industrial symbiosis significantly enhances economic benefits by transforming solid waste into valuable resources through collaborative processes among industries, reducing raw material costs and waste disposal expenses. Traditional solid waste management often incurs high landfill fees and environmental penalties, while industrial symbiosis reduces waste generation and promotes resource efficiency, contributing to cost savings and improved profitability. By leveraging by-products as inputs in other production cycles, industrial symbiosis drives innovation, creates new market opportunities, and supports sustainable economic growth.

Resource Efficiency: Turning Waste Into Value

Solid waste management aims to reduce landfill use through recycling and recovery, whereas industrial symbiosis enhances resource efficiency by exchanging waste materials between industries as valuable inputs. Industrial symbiosis transforms by-products and residues into raw materials, minimizing environmental impact and promoting circular economy practices. This approach not only reduces solid waste volume but also drives innovation in sustainable production and resource optimization.

Regulatory Frameworks: Solid Waste Guidelines vs Symbiosis Incentives

Solid waste management is governed by strict regulatory frameworks such as the Resource Conservation and Recovery Act (RCRA), which mandates proper waste segregation, treatment, and disposal to minimize environmental impact. Industrial symbiosis, conversely, is promoted through policy incentives and collaborative regulations like the European Union's Circular Economy Action Plan that encourage resource sharing and waste exchanges between industries. These contrasting regulatory approaches highlight the shift from traditional waste disposal towards sustainable material reuse and economic symbiosis in industrial ecosystems.

Case Studies: Successful Industrial Symbiosis Initiatives

Successful industrial symbiosis initiatives demonstrate significant reductions in solid waste by enabling companies to exchange by-products as raw materials, minimizing landfill use. Case studies such as Kalundborg Eco-Industrial Park in Denmark showcase how interconnected industries achieve economic and environmental benefits through coordinated waste management and resource sharing. These examples highlight the potential of industrial symbiosis to transform solid waste challenges into sustainable resource cycles.

Barriers to Adoption: Solid Waste Challenges vs Symbiosis Potential

Solid waste management faces significant barriers such as high collection costs, inconsistent segregation, and limited recycling infrastructure, which hinder effective waste reduction. In contrast, industrial symbiosis leverages the exchange of by-products between industries to minimize waste but encounters barriers like regulatory constraints, lack of trust among partners, and logistical complexities. Overcoming these challenges requires integrated policy frameworks and enhanced collaboration to unlock the full potential of industrial symbiosis as a sustainable waste management solution.

Future Trends: Integrating Solid Waste Management with Industrial Symbiosis

Future trends in solid waste management emphasize integrating industrial symbiosis to enhance resource efficiency and reduce environmental impact. By linking waste outputs from one industry as inputs for another, this approach promotes circular economy principles and minimizes landfill dependency. Emerging technologies in waste sorting and real-time data sharing are critical for optimizing these symbiotic relationships and achieving sustainable waste management goals.

Related Important Terms

Urban Mining

Urban mining leverages the extraction of valuable metals and materials from solid waste streams, reducing the dependency on virgin resource extraction and minimizing landfill volumes. Industrial symbiosis enhances urban mining by facilitating the exchange of by-products and waste among industries, promoting resource efficiency and circular economy principles within urban environments.

Circular Economy Loop

Solid waste management plays a critical role in closing the circular economy loop by diverting materials from landfills and enabling resource recovery. Industrial symbiosis enhances this process by facilitating the exchange of by-products and waste materials between industries, reducing overall waste generation and promoting sustainable resource efficiency.

By-product Synergy

By-product synergy in industrial symbiosis transforms solid waste from one industry into valuable input for another, significantly reducing landfill disposal and promoting circular economy practices. This approach enhances resource efficiency, lowers environmental impact, and supports sustainable industrial ecosystem development through collaborative waste valorization.

Resource Cascade

Solid waste management typically involves the disposal or recycling of materials without fully exploiting their potential value, whereas industrial symbiosis emphasizes the resource cascade by facilitating the continuous reuse of by-products and waste streams across industries, thereby maximizing resource efficiency and minimizing environmental impact. Implementing industrial symbiosis strategies transforms solid waste into valuable inputs for other processes, promoting circular economy principles and reducing the extraction of virgin resources.

Material Flow Analysis (MFA)

Material Flow Analysis (MFA) quantifies and visualizes the flow of materials in solid waste management and supports Industrial Symbiosis by identifying opportunities for resource sharing and waste reduction. Integrating MFA enables systematic tracking of waste streams and by-products, enhancing efficiency and sustainability in both solid waste treatment and industrial ecosystem collaboration.

Zero Waste Manufacturing

Zero Waste Manufacturing emphasizes minimizing solid waste generation by integrating Industrial Symbiosis, where by-products from one process serve as raw materials for another, creating closed-loop systems. This collaborative approach significantly reduces landfill dependency and promotes sustainable resource efficiency across industries.

Waste Valorization

Solid waste management traditionally focuses on collection, disposal, and recycling, whereas industrial symbiosis emphasizes waste valorization by transforming by-products from one industry into valuable raw materials for another, enhancing resource efficiency and reducing environmental impact. This approach to waste valorization in industrial symbiosis promotes circular economy principles, minimizes landfill dependency, and fosters sustainable industrial ecosystems.

Industrial Metabolism

Industrial metabolism emphasizes the flow of materials and energy through industrial systems to mimic natural ecosystems, reducing solid waste by transforming by-products into valuable inputs for other processes. This approach underpins industrial symbiosis, where interconnected industries collaborate to optimize resource efficiency and minimize environmental impact.

Symbiotic Network Mapping

Symbiotic network mapping in industrial symbiosis identifies and visualizes the flows of materials, energy, and resources between companies, optimizing waste exchange and minimizing solid waste generation. This approach transforms traditional solid waste management by fostering collaborative resource use, reducing environmental impact, and improving economic efficiency through interconnected industrial ecosystems.

Residual Waste Brokerage

Residual waste brokerage facilitates the efficient management of solid waste by connecting waste producers with industrial symbiosis networks, optimizing resource recovery and minimizing landfill use. This approach transforms residual waste into valuable inputs for industrial processes, driving sustainability and cost reduction in waste management.

Solid Waste vs Industrial Symbiosis Infographic

industrydif.com

industrydif.com