Trash collection involves the regular gathering and disposal of waste from residential and commercial areas, aiming to maintain cleanliness and prevent environmental contamination. Reverse logistics focuses on the efficient return and reuse of products, components, and materials to minimize landfill waste and promote circular economy practices. Integrating reverse logistics into waste management systems enhances resource recovery and reduces overall environmental impact.

Table of Comparison

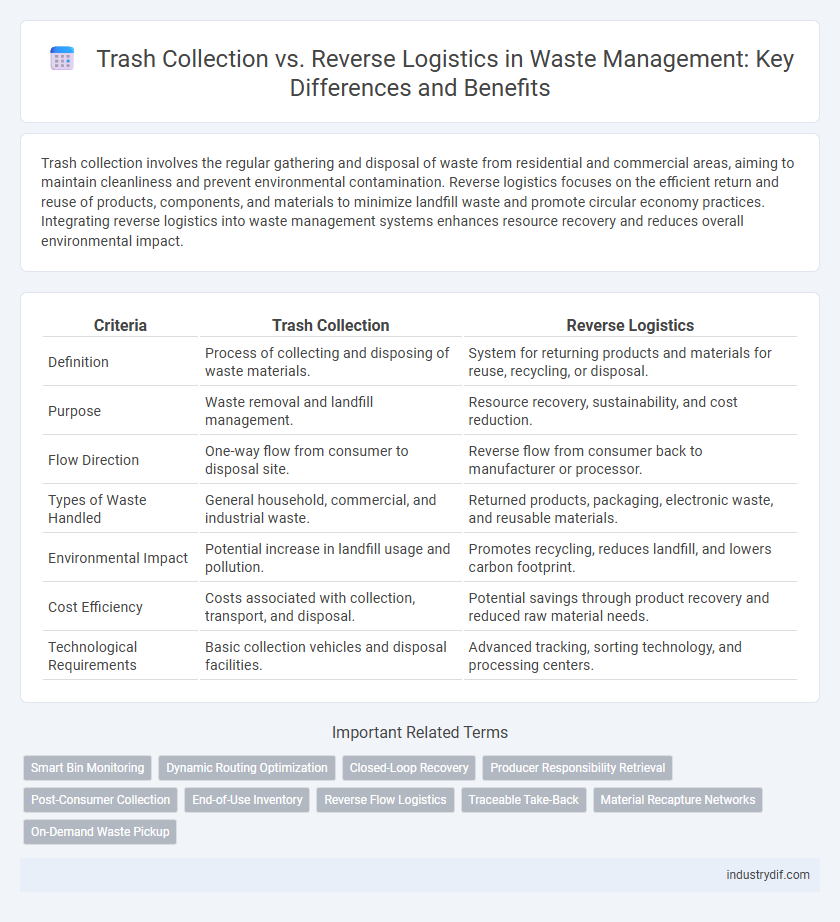

| Criteria | Trash Collection | Reverse Logistics |

|---|---|---|

| Definition | Process of collecting and disposing of waste materials. | System for returning products and materials for reuse, recycling, or disposal. |

| Purpose | Waste removal and landfill management. | Resource recovery, sustainability, and cost reduction. |

| Flow Direction | One-way flow from consumer to disposal site. | Reverse flow from consumer back to manufacturer or processor. |

| Types of Waste Handled | General household, commercial, and industrial waste. | Returned products, packaging, electronic waste, and reusable materials. |

| Environmental Impact | Potential increase in landfill usage and pollution. | Promotes recycling, reduces landfill, and lowers carbon footprint. |

| Cost Efficiency | Costs associated with collection, transport, and disposal. | Potential savings through product recovery and reduced raw material needs. |

| Technological Requirements | Basic collection vehicles and disposal facilities. | Advanced tracking, sorting technology, and processing centers. |

Defining Trash Collection and Reverse Logistics

Trash collection involves the routine gathering and disposal of waste materials from residential, commercial, and industrial sources, focusing on efficient removal and landfill or incineration processes. Reverse logistics, in contrast, manages the return flow of products and packaging from consumers to manufacturers for reuse, recycling, or proper disposal, emphasizing resource recovery and sustainability. Both systems play crucial roles in waste management but differ fundamentally in operational goals and environmental impact.

Key Differences Between Trash Collection and Reverse Logistics

Trash collection primarily involves the gathering and disposal of waste materials from residential, commercial, and industrial sources, focusing on efficient removal and landfill diversion. Reverse logistics centers on the process of returning products or materials back through the supply chain for reuse, remanufacturing, recycling, or proper disposal, emphasizing value recovery and sustainability. Key differences include waste direction--trash collection moves waste outward for disposal, while reverse logistics moves materials backward for recovery--along with distinct operational goals and handling methods.

Role of Waste Management in Trash Collection

Waste management plays a critical role in trash collection by ensuring the efficient segregation, transportation, and disposal of solid waste to minimize environmental impact. Advanced waste management systems integrate technologies such as GPS tracking and route optimization to enhance trash collection efficiency and reduce operational costs. Effective waste management supports reverse logistics by facilitating the recovery and recycling of materials, closing the loop in sustainable waste processing.

The Importance of Reverse Logistics in Circular Economy

Reverse logistics plays a crucial role in the circular economy by enabling the efficient return, recycling, and repurposing of waste materials, reducing the dependency on landfill sites. Unlike traditional trash collection that primarily focuses on disposal, reverse logistics maximizes resource recovery and minimizes environmental impact through systematic product lifecycle management. Implementing reverse logistics systems leads to significant cost savings, lower carbon emissions, and promotes sustainable consumption patterns by closing the loop on material usage.

Collection Processes: Traditional vs Sustainable Approaches

Traditional trash collection relies heavily on scheduled curbside pickups, centralized landfills, and incineration, often resulting in higher carbon emissions and inefficient resource use. Sustainable collection processes in reverse logistics emphasize waste segregation at the source, material recovery facilities, and closed-loop recycling systems to minimize landfill dependency. Advanced technologies like IoT-enabled bins and route optimization software enhance sustainable collection efficiency by reducing fuel consumption and enabling real-time waste monitoring.

Environmental Impact: Disposal vs Resource Recovery

Trash collection primarily contributes to environmental degradation through increased landfill use and methane emissions, whereas reverse logistics emphasizes resource recovery by redirecting waste materials for reuse and recycling, significantly lowering carbon footprints and conserving natural resources. Efficient reverse logistics systems facilitate closed-loop supply chains, reducing the extraction of raw materials and minimizing hazardous waste generation. This shift from disposal toward resource recovery enhances sustainability and promotes circular economy practices, mitigating pollution and supporting long-term environmental health.

Cost Analysis: Trash Collection vs Reverse Logistics

Trash collection often incurs higher operational costs due to fuel consumption, labor, and landfill fees, while reverse logistics leverages streamlined processes to recover value from returned or recyclable materials, reducing overall expenses. Implementing reverse logistics can lead to significant cost savings by minimizing waste disposal fees and generating revenue through refurbishing or reselling products. Detailed cost analysis reveals that reverse logistics optimizes resource allocation and lowers environmental impact, presenting a more sustainable financial model compared to traditional trash collection.

Innovations Transforming Waste Handling

Innovations transforming waste handling reveal a shift from traditional trash collection to advanced reverse logistics systems that prioritize resource recovery and circular economy principles. Smart sensor technologies and AI-driven sorting facilities optimize material segregation, reducing landfill reliance and enhancing recycling rates. Emerging blockchain solutions ensure transparency and traceability in waste streams, supporting efficient reuse, remanufacturing, and sustainable waste management practices.

Regulatory Compliance in Trash Collection and Reverse Logistics

Regulatory compliance in trash collection mandates adherence to strict guidelines on waste segregation, transportation, and disposal to prevent environmental contamination and ensure public health safety. Reverse logistics requires compliance with additional regulations on the handling, refurbishing, and reintroducing of materials, emphasizing proper documentation and traceability to meet legal standards. Both systems must align with local, national, and international environmental laws, such as the Resource Conservation and Recovery Act (RCRA) and international treaties on hazardous waste management.

Future Trends: Integrating Reverse Logistics into Waste Management

Future trends in waste management emphasize the integration of reverse logistics to enhance sustainability and resource recovery. Advanced reverse logistics systems enable efficient collection, sorting, and processing of recyclable materials, reducing landfill dependency and lowering carbon emissions. Smart technologies like IoT and AI optimize waste routes, improve material tracking, and facilitate circular economy practices in urban environments.

Related Important Terms

Smart Bin Monitoring

Smart bin monitoring enhances trash collection efficiency by using IoT sensors to track fill levels, enabling optimized route planning and reduced collection frequency. Integrating this technology with reverse logistics supports sustainable waste management by facilitating the timely retrieval and recycling of reusable materials.

Dynamic Routing Optimization

Dynamic routing optimization significantly enhances trash collection efficiency by minimizing fuel consumption and reducing travel time through real-time data analysis and adaptive route adjustments. Reverse logistics similarly benefits by streamlining the return flow of goods and recyclables, enabling precise scheduling and resource allocation that lower operational costs and environmental impact.

Closed-Loop Recovery

Trash collection traditionally involves the gathering and disposal of solid waste, whereas reverse logistics emphasizes the systematic return and reuse of materials to support closed-loop recovery. Closed-loop recovery enhances sustainability by reintegrating recovered products into production cycles, reducing landfill dependency and promoting resource efficiency.

Producer Responsibility Retrieval

Producer Responsibility Retrieval enhances waste management by ensuring manufacturers actively collect and recycle end-of-life products, reducing landfill dependence. This approach integrates reverse logistics systems that streamline the return of goods from consumers, optimizing resource recovery and minimizing environmental impact.

Post-Consumer Collection

Post-consumer collection in waste management emphasizes efficient trash collection systems that directly retrieve discarded consumer products for recycling or disposal, reducing landfill impact and promoting sustainability. Reverse logistics extends this process by integrating return flows of used goods back into supply chains, enabling product refurbishment, recycling, and resource recovery, ultimately enhancing circular economy practices.

End-of-Use Inventory

Trash collection primarily handles end-of-use Inventory by gathering and disposing of waste materials efficiently, while reverse logistics focuses on reclaiming value from these products through processes like remanufacturing, refurbishing, or recycling. Effective management of end-of-use inventory through reverse logistics reduces landfill volumes, supports circular economy initiatives, and maximizes resource recovery.

Reverse Flow Logistics

Reverse flow logistics streamlines the process of returning, recycling, and redistributing waste materials, significantly enhancing resource recovery and reducing landfill dependence. This approach contrasts with traditional trash collection by emphasizing circular economy principles and optimizing the supply chain for waste reuse and remanufacturing.

Traceable Take-Back

Traceable take-back systems in reverse logistics enable precise tracking of waste from consumer to recycler, enhancing accountability and reducing landfill overflow compared to traditional trash collection methods. Implementing digital tracking technologies in reverse logistics improves data accuracy for waste streams, facilitating regulatory compliance and promoting circular economy practices.

Material Recapture Networks

Material recapture networks in waste management optimize resource recovery by integrating trash collection systems with reverse logistics processes, enabling efficient sorting, transportation, and processing of recyclable materials. These networks reduce landfill dependency and promote circular economy principles by maximizing the value extracted from post-consumer waste through coordinated reverse supply chains.

On-Demand Waste Pickup

On-demand waste pickup enhances efficiency by allowing users to schedule trash collection precisely when needed, reducing unnecessary trips and lowering carbon emissions compared to traditional fixed-route methods. Integrating reverse logistics in this system optimizes resource recovery and waste sorting, promoting sustainability and cost savings for municipalities and businesses.

Trash Collection vs Reverse Logistics Infographic

industrydif.com

industrydif.com