Single-stream recycling simplifies waste sorting by allowing all recyclables to be placed in one bin, increasing participation but often leading to contamination and lower material quality. Multi-layer plastic recycling targets complex packaging by separating layers for more efficient recovery, though it requires advanced technology and higher costs. Choosing the right method depends on balancing convenience, contamination rates, and the efficiency of recycling different plastic types.

Table of Comparison

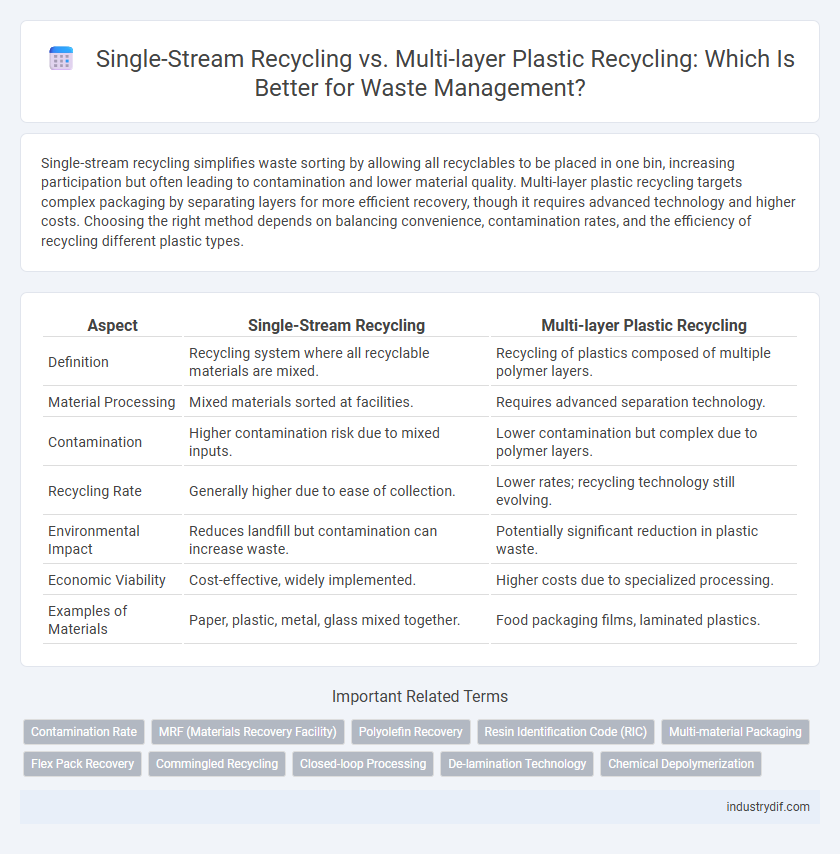

| Aspect | Single-Stream Recycling | Multi-layer Plastic Recycling |

|---|---|---|

| Definition | Recycling system where all recyclable materials are mixed. | Recycling of plastics composed of multiple polymer layers. |

| Material Processing | Mixed materials sorted at facilities. | Requires advanced separation technology. |

| Contamination | Higher contamination risk due to mixed inputs. | Lower contamination but complex due to polymer layers. |

| Recycling Rate | Generally higher due to ease of collection. | Lower rates; recycling technology still evolving. |

| Environmental Impact | Reduces landfill but contamination can increase waste. | Potentially significant reduction in plastic waste. |

| Economic Viability | Cost-effective, widely implemented. | Higher costs due to specialized processing. |

| Examples of Materials | Paper, plastic, metal, glass mixed together. | Food packaging films, laminated plastics. |

Overview of Single-Stream Recycling

Single-stream recycling allows households to place all recyclables, including paper, plastics, metals, and glass, into a single collection bin, simplifying waste sorting at the source. This system increases participation rates and collection volumes but often leads to higher contamination levels, affecting the efficiency of material recovery facilities (MRFs). While convenient for consumers and waste management services, the mixed nature of single-stream recycling requires advanced sorting technology to separate recyclable materials effectively.

Understanding Multi-layer Plastic Recycling

Multi-layer plastic recycling involves the processing of packaging materials composed of multiple polymer layers, which provide enhanced barrier properties but complicate separation and recycling. Advanced technologies like solvent-based delamination and chemical recycling enable the recovery of individual polymers without degrading their quality. Effective multi-layer plastic recycling reduces environmental impact by diverting complex waste from landfills and promoting circular economy principles within plastic waste management.

Key Differences Between Single-Stream and Multi-layer Recycling

Single-stream recycling collects all recyclable materials in one bin, simplifying sorting but increasing contamination risks and reducing material quality. Multi-layer plastic recycling involves separating distinct plastic layers, enhancing the purity and recyclability of each component but requiring advanced sorting technology and higher processing costs. These key differences impact the efficiency, cost, and environmental outcomes of recycling programs.

Collection Processes in Single-Stream Systems

Single-stream recycling collection processes streamline the sorting phase by combining all recyclables--paper, plastics, metals, and glass--into a single bin, reducing the need for separate containers. This method improves participation rates and collection efficiency but demands advanced sorting technologies at material recovery facilities to separate mixed materials. Effective single-stream systems rely on automated equipment like optical sorters and air classifiers to manage contamination and ensure high-quality recyclables for downstream processing.

Challenges in Recycling Multi-layer Plastics

Recycling multi-layer plastics presents significant challenges due to the complex combination of different polymers and adhesives, which complicate sorting and material recovery processes. Single-stream recycling systems struggle to effectively separate these materials, leading to contamination and reduced quality of recycled output. Advanced technologies like solvent-based separation and specialized mechanical recycling are necessary but often costly and not widely implemented, limiting multi-layer plastics recycling rates.

Sorting Technologies and Innovations

Single-stream recycling relies heavily on advanced optical sorting technologies such as near-infrared (NIR) sensors and laser-induced fluorescence to efficiently separate mixed recyclables, improving collection convenience but often resulting in higher contamination rates. In contrast, multi-layer plastic recycling demands innovative sorting methods like density separation, electrostatic sorting, and novel solvent-based recycling techniques to effectively separate complex polymer layers, enhancing material recovery and quality. Emerging AI-driven robotics and hyperspectral imaging further optimize sorting precision, reducing manual labor and increasing throughput in both systems.

Environmental Impact Comparison

Single-stream recycling often leads to higher contamination rates, reducing the quality of recycled materials and increasing landfill waste. In contrast, multi-layer plastic recycling, though technically challenging, enables the reuse of complex packaging materials, significantly lowering resource extraction and greenhouse gas emissions. Lifecycle assessments reveal that optimizing multi-layer plastic recycling processes offers greater environmental benefits by conserving energy and reducing plastic pollution.

Contamination Issues in Single-Stream Recycling

Single-stream recycling faces significant contamination issues due to the commingling of various materials, which complicates the sorting process and reduces the quality of recyclables. Multi-layer plastic recycling, by contrast, often deals with contamination at the material level, but it benefits from more controlled input streams that enhance purity. Contamination in single-stream recycling leads to higher rejection rates at material recovery facilities, ultimately increasing landfill waste and reducing recycling efficiency.

Economic Viability and Market Demand

Single-stream recycling offers cost advantages through streamlined collection and sorting processes, enabling higher participation rates and reducing labor expenses. Multi-layer plastic recycling faces economic challenges due to complex material separation and lower market demand for recycled outputs, which limits profitability. Increasing consumer awareness and regulatory incentives are gradually boosting market demand for multi-layer plastic recycling technologies.

Future Trends in Recycling Industry

Future trends in the recycling industry emphasize advancements in single-stream recycling technologies to enhance sorting efficiency and reduce contamination rates, facilitating higher material recovery. Multi-layer plastic recycling is gaining traction through innovative chemical recycling methods that break down complex polymers, enabling the recovery of valuable resins previously considered non-recyclable. Integration of AI-powered sorting systems and increased investments in circular economy initiatives are shaping the scalability and sustainability of both recycling streams, driving improved environmental outcomes.

Related Important Terms

Contamination Rate

Single-stream recycling systems exhibit higher contamination rates, often exceeding 20%, due to the mixing of various materials that complicates sorting processes and reduces the quality of recovered plastics. Multi-layer plastic recycling, while technically challenging, benefits from specialized separation techniques that lower contamination levels and improve the efficiency of reclaiming valuable polymers.

MRF (Materials Recovery Facility)

Single-stream recycling simplifies sorting at Materials Recovery Facilities (MRFs) by collecting all recyclables together, but often leads to higher contamination rates and reduced Quality of recovered materials, particularly with multi-layer plastics. Multi-layer plastic recycling requires advanced sorting technologies at MRFs to effectively separate composite materials, enhancing the recovery rate and enabling more efficient recycling of complex packaging.

Polyolefin Recovery

Single-stream recycling simplifies collection but often leads to contamination that reduces the efficiency of polyolefin recovery, while multi-layer plastic recycling, although more complex, enables targeted separation techniques that enhance the purification and reuse of polyolefins such as polyethylene and polypropylene. Optimizing polyolefin recovery improves material quality and supports circular economy goals by reducing reliance on virgin plastics and minimizing landfill waste.

Resin Identification Code (RIC)

Single-stream recycling systems often struggle with accurately sorting materials due to the mixing of different resin codes, which complicates the processing of multi-layer plastics identified by Resin Identification Codes (RIC) 7. Multi-layer plastics frequently fall under RIC 7, representing complex composites that require specialized recycling methods distinct from the more straightforward resin types labeled 1 through 6, emphasizing the need for targeted sorting technology to improve recycling efficiency.

Multi-material Packaging

Multi-material packaging presents significant challenges for recycling due to the complex layering of plastic, metal, and paper components that hinder efficient separation and material recovery. Multi-layer plastic recycling technologies aim to improve the circularity of single-stream recycling systems by selectively processing each polymer layer, enhancing material purity and reducing contamination in recycled outputs.

Flex Pack Recovery

Single-stream recycling simplifies collection by combining all recyclables into one bin, but it often results in contamination that reduces the quality of recovered materials, particularly flexible packaging (flex pack). Multi-layer plastic recycling, although more complex, targets flex pack recovery specifically by using advanced sorting and processing technologies to separate and recycle the diverse polymer layers, significantly improving material reclamation rates and reducing landfill waste.

Commingled Recycling

Commingled recycling, also known as single-stream recycling, simplifies waste sorting by collecting all recyclables in one bin, increasing participation rates but often leading to higher contamination levels that reduce the quality of recovered materials. In contrast, multi-layer plastic recycling requires separation of materials by type, enabling more efficient recovery of composite plastics yet demanding more complex sorting infrastructure.

Closed-loop Processing

Single-stream recycling collects all recyclables together, simplifying consumer participation but often resulting in higher contamination rates that challenge closed-loop processing efficiency. Multi-layer plastic recycling employs specialized techniques to separate and reprocess composite materials, enabling a more effective closed-loop system that preserves material quality and supports sustainable plastic product manufacturing.

De-lamination Technology

De-lamination technology enhances the efficiency of multi-layer plastic recycling by separating different polymer layers, enabling higher-quality material recovery compared to single-stream recycling, which often results in contamination and lower purity. This process reduces landfill waste and supports circular economy goals by enabling the reuse of complex plastic packaging that single-stream systems cannot effectively process.

Chemical Depolymerization

Chemical depolymerization in multi-layer plastic recycling enables the breakdown of complex polymers into their monomers, facilitating efficient recovery of high-purity materials that single-stream recycling cannot achieve due to contamination and mixed materials. This advanced process enhances circularity by converting multi-layer plastics, commonly found in packaging waste, into reusable feedstocks, significantly reducing landfill dependency and environmental impact.

Single-Stream Recycling vs Multi-layer Plastic Recycling Infographic

industrydif.com

industrydif.com