Scrap metal recycling involves collecting and processing discarded metal materials from conventional sources such as old vehicles, appliances, and construction debris. Urban mining, however, extracts valuable metals directly from electronic waste and complex urban materials, offering a more targeted approach to resource recovery. Both methods reduce the demand for virgin metal extraction, but urban mining capitalizes on the high concentration of precious metals found in modern electronic devices.

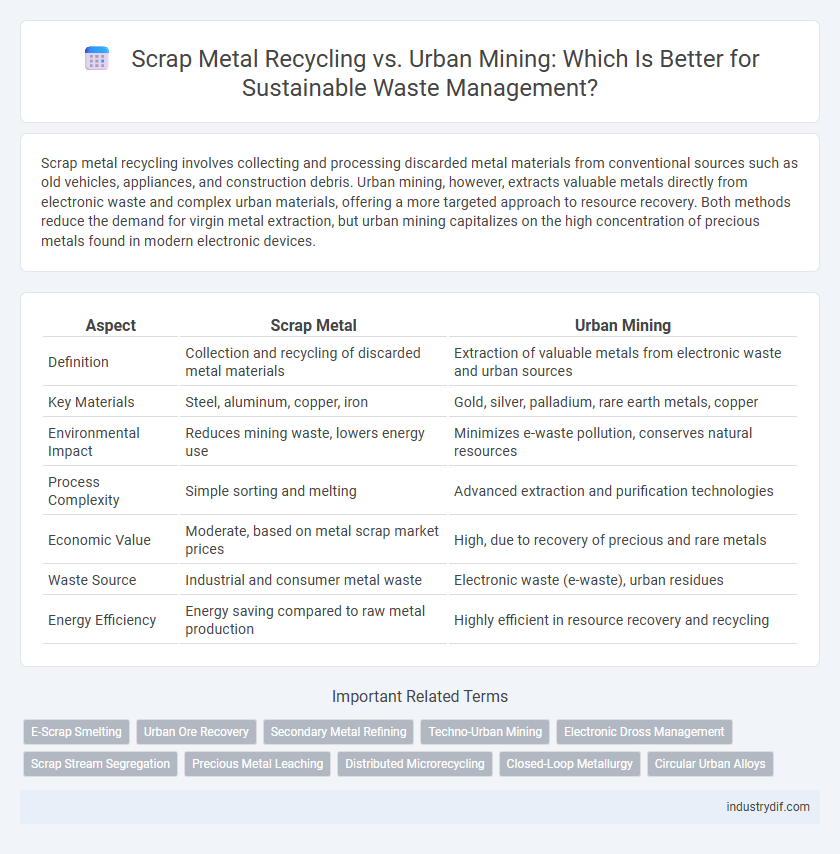

Table of Comparison

| Aspect | Scrap Metal | Urban Mining |

|---|---|---|

| Definition | Collection and recycling of discarded metal materials | Extraction of valuable metals from electronic waste and urban sources |

| Key Materials | Steel, aluminum, copper, iron | Gold, silver, palladium, rare earth metals, copper |

| Environmental Impact | Reduces mining waste, lowers energy use | Minimizes e-waste pollution, conserves natural resources |

| Process Complexity | Simple sorting and melting | Advanced extraction and purification technologies |

| Economic Value | Moderate, based on metal scrap market prices | High, due to recovery of precious and rare metals |

| Waste Source | Industrial and consumer metal waste | Electronic waste (e-waste), urban residues |

| Energy Efficiency | Energy saving compared to raw metal production | Highly efficient in resource recovery and recycling |

Introduction to Scrap Metal and Urban Mining

Scrap metal refers to discarded metal materials that can be recycled and reused, reducing the need for raw metal extraction and minimizing environmental impact. Urban mining involves recovering valuable metals and other resources from electronic waste, buildings, and infrastructure within cities, efficiently tapping into secondary raw materials. Both processes contribute significantly to sustainable waste management by promoting resource recovery and reducing landfill use.

Defining Scrap Metal Recovery

Scrap metal recovery involves collecting and processing discarded metal materials from various sources, such as manufacturing waste, end-of-life products, and construction debris, to reclaim valuable metals like steel, aluminum, copper, and brass. Urban mining refers to extracting these metals from electronic waste, obsolete vehicles, and building materials found in urban environments, emphasizing resource efficiency and reducing the need for virgin ore mining. Both processes contribute significantly to sustainable waste management by minimizing landfill use and lowering environmental impact through metal recycling and reuse.

What Is Urban Mining?

Urban mining is the process of reclaiming raw materials from electronic waste, discarded appliances, and other scrap metals typically found in urban environments. It involves extracting valuable metals like copper, aluminum, gold, and rare earth elements from end-of-life products, reducing the reliance on traditional mining and minimizing environmental impact. Unlike conventional scrap metal recycling, urban mining emphasizes the recovery of metals embedded within complex waste streams, promoting sustainable resource management and circular economy principles.

Sources of Recyclable Materials

Scrap metal primarily originates from end-of-life vehicles, machinery, and construction debris, providing a concentrated and accessible source of recyclable materials. Urban mining, on the other hand, targets electronic waste, discarded appliances, and obsolete infrastructure, recovering valuable metals often overlooked in conventional recycling streams. Both methods contribute significantly to reducing the demand for virgin ore extraction by tapping into diverse, sustainable material sources within urban environments.

Key Processes: Scrap Metal vs Urban Mining

Scrap metal processing involves collection, sorting, and melting of discarded metals to produce reusable raw materials, emphasizing traditional recycling tools and manual labor. Urban mining leverages advanced technologies like sensor-based sorting, shredding, and hydrometallurgical extraction to recover precious metals from electronic waste and complex consumer products. Both processes prioritize resource recovery but differ significantly in scope, with urban mining targeting a broader range of materials and promoting circular economy principles.

Environmental Impact Comparison

Scrap metal recycling reduces the need for virgin ore extraction, significantly lowering greenhouse gas emissions and energy consumption compared to traditional mining. Urban mining leverages waste electrical and electronic equipment, recovering valuable metals with minimal environmental disturbance and reducing landfill waste. Both methods contribute to sustainable resource management, but urban mining offers a higher potential for reducing toxic waste and conserving natural habitats.

Economic Value and Market Trends

Scrap metal recycling generates significant economic value by supplying raw materials to industries, reducing the need for costly mining operations and lowering production costs. Urban mining, the process of recovering valuable metals from electronic waste, is growing rapidly due to rising metal prices and increasing regulatory pressures for resource sustainability. Market trends indicate a shift toward urban mining investments as it offers higher yields of precious metals like gold, silver, and platinum, driving profitability in circular economy models.

Technological Innovations in Recovery

Technological innovations in scrap metal recovery include advanced sorting systems using AI-driven sensors and robotic arms that enhance material purity and recycling efficiency. Urban mining leverages cutting-edge techniques such as hydrometallurgical processes and bioleaching to extract valuable metals from electronic waste and obsolete infrastructure. Both approaches benefit from real-time data analytics and automation, significantly improving recovery rates and reducing environmental impact.

Challenges in Collection and Sorting

Scrap metal collection faces challenges such as contamination, illegal dumping, and a lack of efficient sorting technologies, impacting the quality and market value of recycled materials. Urban mining encounters difficulties in identifying and extracting valuable metals from complex waste streams, including electronic waste, which requires advanced sorting methods like sensor-based separation and automated dismantling. Both processes demand improved infrastructure and regulatory support to optimize recovery rates and reduce environmental impacts.

Future Outlook for Resource Sustainability

Scrap metal recycling and urban mining both play crucial roles in achieving resource sustainability by reducing dependence on virgin raw materials and minimizing environmental impact. Urban mining, which involves recovering metals from electronic waste and complex products, is expected to grow significantly with advancements in automated sorting and material recovery technologies. The future outlook highlights increased integration of circular economy principles, promoting efficient resource use and fostering sustainable development through innovative waste management practices.

Related Important Terms

E-Scrap Smelting

E-scrap smelting efficiently recovers valuable metals like copper, gold, and silver from discarded electronics through high-temperature processes, offering a cost-effective alternative to traditional scrap metal recycling. Urban mining leverages e-scrap smelting to extract critical raw materials from electronic waste, reducing environmental impact and dependence on virgin metal mining.

Urban Ore Recovery

Urban ore recovery leverages advanced technologies to extract valuable metals from electronic waste, construction debris, and discarded appliances, significantly reducing reliance on traditional scrap metal sources. This method enhances resource efficiency by reclaiming critical elements like copper, gold, and rare earth metals from urban environments, promoting sustainable waste management and circular economy practices.

Secondary Metal Refining

Scrap metal collection serves as a primary source of raw materials for secondary metal refining, enabling the recovery of valuable metals like steel, aluminum, and copper with significantly lower energy consumption than primary extraction. Urban mining, which involves reclaiming metals from electronic waste and obsolete infrastructure, enhances secondary refining processes by providing a diversified and high-purity feedstock for sustainable metal production.

Techno-Urban Mining

Techno-Urban Mining leverages advanced technologies such as AI-driven sensors and automated sorting systems to efficiently extract valuable metals from electronic waste, offering a sustainable alternative to traditional scrap metal recycling methods. This innovative approach maximizes resource recovery, reduces environmental impact, and supports circular economy goals by reclaiming metals embedded within urban infrastructures.

Electronic Dross Management

Scrap metal recycling primarily involves recovering valuable metals from discarded electronic dross, reducing environmental impact and conserving natural resources through efficient metal reclamation processes. Urban mining enhances electronic dross management by extracting critical metals from e-waste, promoting circular economy principles and minimizing landfill accumulation.

Scrap Stream Segregation

Effective scrap stream segregation enhances resource recovery by separating ferrous and non-ferrous metals, reducing contamination and enabling efficient recycling. Urban mining leverages segregated scrap streams from electronic waste and construction debris to recover valuable metals, minimizing environmental impact and promoting circular economy practices.

Precious Metal Leaching

Precious metal leaching in scrap metal processing involves chemically extracting valuable metals such as gold, silver, and platinum from electronic waste and discarded materials, optimizing resource recovery and reducing environmental impact. Urban mining leverages this process by reclaiming precious metals from complex urban waste streams, offering a sustainable alternative to traditional mining and promoting circular economy principles.

Distributed Microrecycling

Distributed microrecycling enhances urban mining by enabling localized processing of scrap metal, reducing transportation emissions and improving raw material recovery rates. This approach leverages decentralized facilities to efficiently reclaim valuable metals from electronic waste and end-of-life products, supporting sustainable resource management.

Closed-Loop Metallurgy

Closed-loop metallurgy enhances resource efficiency by integrating scrap metal recycling with urban mining, enabling continuous material recovery and reducing reliance on virgin ores. This sustainable approach minimizes environmental impact while maximizing metal reuse in manufacturing processes.

Circular Urban Alloys

Circular Urban Alloys leverage urban mining techniques to extract valuable metals from scrap metal found in electronic waste, construction debris, and discarded vehicles, reducing the need for virgin material extraction. This innovative approach enhances resource efficiency by transforming urban waste streams into high-quality alloy inputs, supporting sustainable metal recycling and lowering environmental impact.

Scrap Metal vs Urban Mining Infographic

industrydif.com

industrydif.com