Single-use plastics contribute significantly to environmental pollution due to their non-biodegradable nature and long decomposition times. Compostable packaging offers an eco-friendly alternative by breaking down naturally and enriching soil without leaving harmful residues. Transitioning to compostable materials reduces landfill waste and supports sustainable waste management practices.

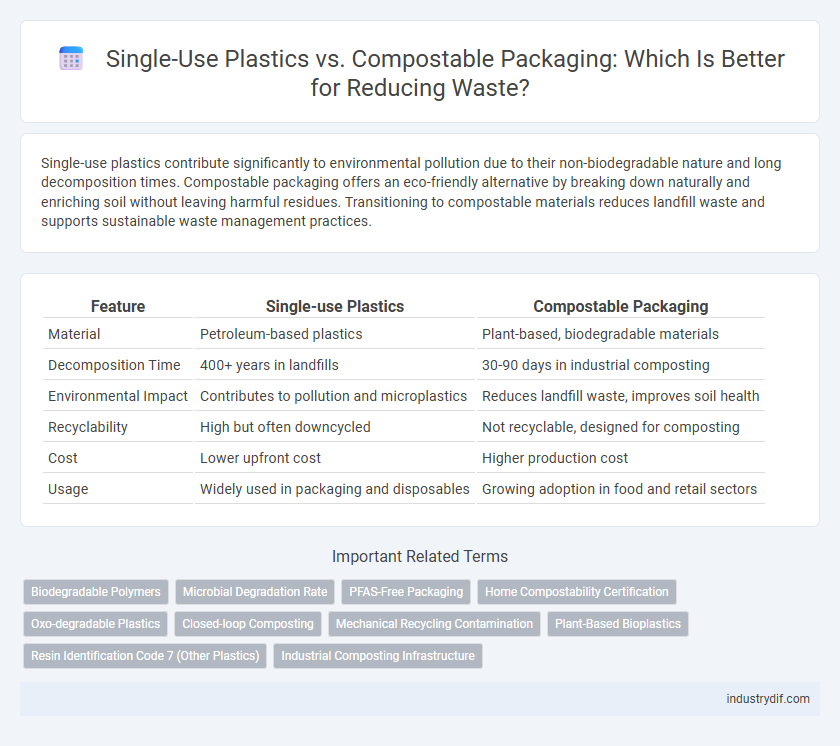

Table of Comparison

| Feature | Single-use Plastics | Compostable Packaging |

|---|---|---|

| Material | Petroleum-based plastics | Plant-based, biodegradable materials |

| Decomposition Time | 400+ years in landfills | 30-90 days in industrial composting |

| Environmental Impact | Contributes to pollution and microplastics | Reduces landfill waste, improves soil health |

| Recyclability | High but often downcycled | Not recyclable, designed for composting |

| Cost | Lower upfront cost | Higher production cost |

| Usage | Widely used in packaging and disposables | Growing adoption in food and retail sectors |

Defining Single-use Plastics and Compostable Packaging

Single-use plastics are disposable materials designed for one-time use and include items like plastic straws, cutlery, and bags that contribute significantly to environmental pollution due to their long decomposition periods. Compostable packaging, made from plant-based materials such as cornstarch or sugarcane fiber, breaks down into organic matter within a controlled composting environment, reducing landfill waste and supporting soil health. Understanding these definitions highlights the environmental impact differences and waste management challenges associated with each packaging type.

Environmental Impact: Single-use Plastics vs Compostables

Single-use plastics contribute significantly to environmental pollution, persisting in ecosystems for hundreds of years and harming marine life through microplastic contamination. Compostable packaging, made from plant-based materials like PLA or bagasse, breaks down within months under industrial composting conditions, reducing landfill waste and greenhouse gas emissions. Lifecycle assessments reveal compostable packaging has a lower carbon footprint compared to traditional plastics, promoting sustainable waste management and circular economy practices.

Lifecycle Analysis of Packaging Materials

Lifecycle analysis reveals single-use plastics contribute significantly to greenhouse gas emissions and persist in landfills for centuries, causing long-term environmental harm. Compostable packaging, derived from renewable resources like cornstarch or sugarcane, breaks down within months under industrial composting conditions, reducing waste accumulation and soil contamination. Despite higher initial production energy, compostable materials often result in lower overall environmental impact through decreased pollution and improved end-of-life biodegradability.

Production Costs and Economic Implications

Single-use plastics typically have lower production costs due to established manufacturing processes and abundant raw materials like petroleum, making them economically attractive for mass production. Compostable packaging, while more expensive to produce because of specialized materials such as polylactic acid (PLA) and biopolymers, offers long-term savings by reducing waste management expenses and environmental cleanup costs. Economically, shifting to compostable packaging can stimulate green industry growth and create jobs, but requires initial investment and consumer willingness to bear higher product prices.

Decomposition Rates and End-of-Life Scenarios

Single-use plastics can take up to 500 years to decompose, leading to long-term environmental pollution and landfill overflow. Compostable packaging typically breaks down within 90 to 180 days under industrial composting conditions, converting into nutrient-rich soil amendments. End-of-life scenarios for compostable materials require proper composting facilities, while single-use plastics often end up in landfills or oceans, contributing to microplastic contamination.

Regulatory Policies and Industry Standards

Regulatory policies increasingly target single-use plastics by imposing bans, taxes, and restrictions to reduce environmental impact, while promoting compostable packaging through certification standards such as ASTM D6400 and EN 13432. Industry standards emphasize material biodegradability, compostability under industrial conditions, and lifecycle assessments to ensure sustainable alternatives. Compliance with these regulations and standards drives market shifts towards eco-friendly packaging solutions, supporting circular economy goals and reducing plastic pollution.

Consumer Perceptions and Market Trends

Consumer perceptions increasingly favor compostable packaging over single-use plastics due to growing environmental awareness and demand for sustainable alternatives. Market trends reveal a significant rise in the adoption of compostable materials, driven by regulatory pressures and consumer preference shifts towards eco-friendly products. Companies investing in innovative compostable packaging technologies are experiencing enhanced brand loyalty and market competitiveness.

Challenges in Recycling and Composting Infrastructure

Single-use plastics present significant challenges in recycling due to contamination and limited processing facilities, leading to low recovery rates and environmental pollution. Compostable packaging requires specialized industrial composting infrastructure, which is often scarce or absent, causing compostable materials to end up in landfills where they fail to degrade properly. Both waste streams highlight gaps in current infrastructure that hinder effective recycling and composting, necessitating investment in advanced sorting technologies and expansion of certified composting programs.

Comparing Carbon Footprints

Single-use plastics generate approximately 6 kg of CO2 emissions per kg of material produced, contributing significantly to global warming. Compostable packaging, made from renewable resources like PLA or cellulose, typically emits 2-3 kg of CO2 per kg, offering a lower carbon footprint throughout its lifecycle. However, the environmental benefits of compostable packaging depend on proper industrial composting conditions, which are often limited in availability.

Future Innovations in Sustainable Packaging

Emerging innovations in sustainable packaging prioritize biodegradable composites and bio-based polymers to replace single-use plastics, drastically reducing environmental impact. Companies invest in enzymatic recycling and nanocellulose materials, offering enhanced durability and compostability without compromising functionality. These advancements signal a scalable shift towards circular economies, minimizing waste accumulation in landfills and marine ecosystems.

Related Important Terms

Biodegradable Polymers

Biodegradable polymers used in compostable packaging break down through microbial activity within months, significantly reducing environmental pollution compared to single-use plastics that can persist for centuries. These polymers, often derived from renewable resources like polylactic acid (PLA) or polyhydroxyalkanoates (PHA), offer sustainable disposal options aligned with circular economy principles.

Microbial Degradation Rate

Single-use plastics persist in the environment for hundreds of years due to their low microbial degradation rate, often exceeding 400 years. Compostable packaging, made from bio-based materials like polylactic acid (PLA), breaks down significantly faster within months under industrial composting conditions, promoting faster nutrient recycling and reduced environmental impact.

PFAS-Free Packaging

PFAS-free compostable packaging offers a sustainable alternative to single-use plastics by eliminating toxic per- and polyfluoroalkyl substances, which are persistent environmental pollutants linked to health risks. By adopting compostable materials free from PFAS, industries can reduce plastic pollution and promote safer waste decomposition in landfills and composting facilities.

Home Compostability Certification

Home compostability certification ensures that compostable packaging breaks down safely and completely in typical household composting conditions, reducing plastic pollution from single-use plastics. Unlike conventional single-use plastics that persist in the environment for hundreds of years, certified home compostable packaging supports sustainable waste management and soil health by decomposing within weeks to months.

Oxo-degradable Plastics

Oxo-degradable plastics contain additives that trigger fragmentation under oxidative conditions but do not fully biodegrade, leading to persistent microplastic pollution. Compared to compostable packaging certified to break down into non-toxic components within industrial composting facilities, oxo-degradable plastics pose greater environmental risks and fail to meet sustainable waste management standards.

Closed-loop Composting

Closed-loop composting transforms single-use compostable packaging into nutrient-rich soil, reducing landfill waste and carbon footprints significantly compared to conventional single-use plastics. This sustainable cycle enhances organic waste management by enabling materials like bioplastics and paper-based packaging to fully decompose within commercial composting facilities, promoting environmental regeneration.

Mechanical Recycling Contamination

Mechanical recycling of single-use plastics often faces significant contamination challenges due to food residues and mixed polymer types, reducing the quality and recyclability of recovered materials. Compostable packaging, designed to biodegrade in industrial facilities, minimizes mechanical recycling contamination but requires dedicated composting infrastructure to prevent cross-stream pollution and ensure effective waste management.

Plant-Based Bioplastics

Plant-based bioplastics derived from renewable resources like cornstarch and sugarcane offer a sustainable alternative to single-use plastics by being compostable and reducing landfill waste. These bioplastics decompose naturally under industrial composting conditions, significantly lowering environmental impact compared to conventional petroleum-based plastics that persist for centuries.

Resin Identification Code 7 (Other Plastics)

Resin Identification Code 7 (Other Plastics) includes a variety of plastic types often found in single-use plastics that pose challenges for recycling due to their mixed composition and low recovery rates. Compostable packaging made from certified biopolymers provides a sustainable alternative by breaking down in industrial composting facilities, reducing landfill waste and environmental pollution caused by persistent plastics.

Industrial Composting Infrastructure

Industrial composting infrastructure is essential for effectively processing compostable packaging, as it requires controlled conditions of temperature, moisture, and microbial activity to break down materials efficiently. Unlike single-use plastics that persist in landfills and oceans, compostable packaging relies on this specialized infrastructure to reduce environmental impact and close the waste loop through biodegradable waste management.

Single-use Plastics vs Compostable Packaging Infographic

industrydif.com

industrydif.com