Chlorination effectively eliminates bacteria and viruses in water through chemical oxidation, but it can produce harmful disinfection byproducts and alter taste. UV-C LED disinfection offers a chemical-free alternative by using ultraviolet light to inactivate microorganisms without generating toxic residues. This innovative technology provides energy-efficient, environmentally friendly water purification with minimal maintenance requirements.

Table of Comparison

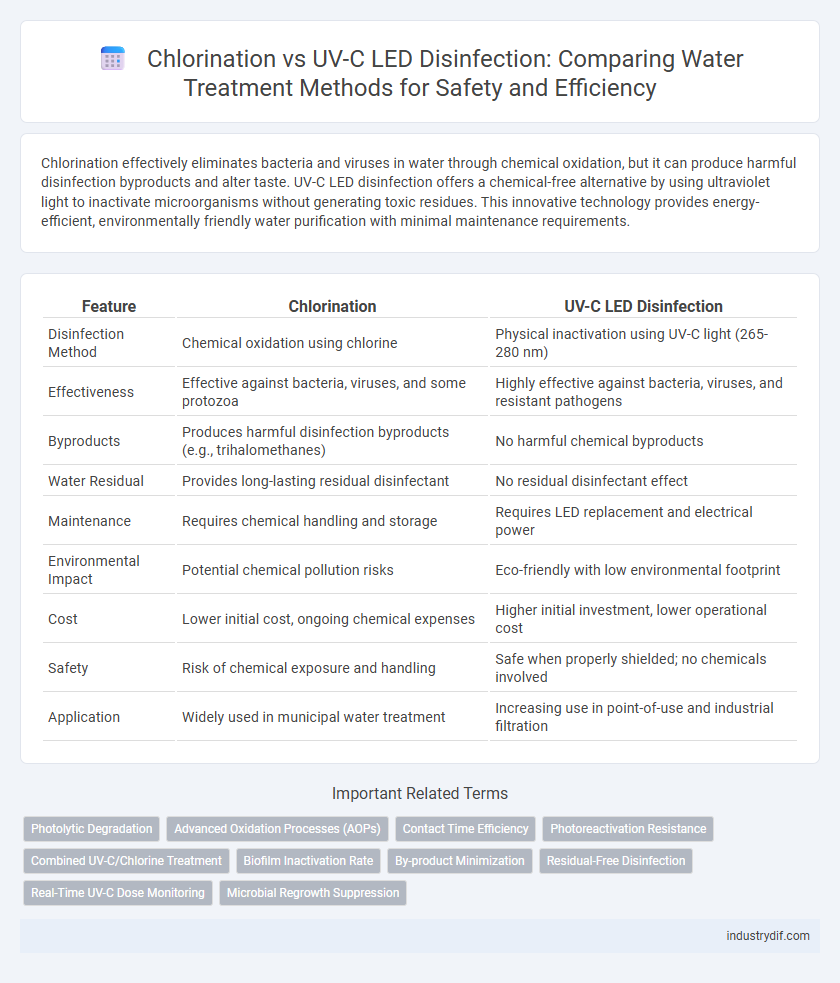

| Feature | Chlorination | UV-C LED Disinfection |

|---|---|---|

| Disinfection Method | Chemical oxidation using chlorine | Physical inactivation using UV-C light (265-280 nm) |

| Effectiveness | Effective against bacteria, viruses, and some protozoa | Highly effective against bacteria, viruses, and resistant pathogens |

| Byproducts | Produces harmful disinfection byproducts (e.g., trihalomethanes) | No harmful chemical byproducts |

| Water Residual | Provides long-lasting residual disinfectant | No residual disinfectant effect |

| Maintenance | Requires chemical handling and storage | Requires LED replacement and electrical power |

| Environmental Impact | Potential chemical pollution risks | Eco-friendly with low environmental footprint |

| Cost | Lower initial cost, ongoing chemical expenses | Higher initial investment, lower operational cost |

| Safety | Risk of chemical exposure and handling | Safe when properly shielded; no chemicals involved |

| Application | Widely used in municipal water treatment | Increasing use in point-of-use and industrial filtration |

Overview of Water Disinfection Methods

Chlorination remains a widely used water disinfection method due to its effectiveness against a broad spectrum of pathogens and residual disinfectant properties that help prevent recontamination. UV-C LED disinfection, emerging as an advanced technology, uses ultraviolet light at specific wavelengths to inactivate microorganisms without chemical byproducts, making it environmentally friendly and safe for sensitive applications. Both methods contribute to water safety, with chlorination favored for large-scale municipal systems and UV-C LED ideal for point-of-use treatment and applications requiring chemical-free processes.

Introduction to Chlorination

Chlorination is a widely used water disinfection method that employs chlorine or chlorine compounds to eliminate pathogens and harmful microorganisms. It effectively controls bacteria, viruses, and protozoa, ensuring safe drinking water in municipal and industrial applications. Chlorination also provides a residual disinfectant effect, maintaining water quality throughout the distribution system.

Introduction to UV-C LED Disinfection

UV-C LED disinfection utilizes ultraviolet light at specific wavelengths (200-280 nm) to effectively inactivate bacteria, viruses, and protozoa in water without chemical additives. Compared to traditional chlorination, UV-C LEDs offer rapid microbial control with minimal formation of harmful disinfection byproducts like trihalomethanes and chloramines. The compact size, energy efficiency, and instant on/off capability of UV-C LED systems make them ideal for decentralized and point-of-use water treatment applications.

Mechanisms of Chlorination

Chlorination disinfects water by releasing free chlorine, primarily hypochlorous acid (HOCl), which penetrates microbial cell walls causing oxidative damage to proteins, enzymes, and nucleic acids. This mechanism effectively inactivates bacteria, viruses, and protozoa by disrupting cellular metabolism and integrity. Residual chlorine also provides ongoing protection against microbial recontamination in distribution systems.

Mechanisms of UV-C LED Disinfection

UV-C LED disinfection employs ultraviolet light at wavelengths between 260-280 nm to disrupt the DNA and RNA of microorganisms, rendering them unable to reproduce and cause infection. Unlike chlorination, which relies on chemical oxidation to neutralize pathogens, UV-C LEDs provide a physical, non-chemical sanitization method that leaves no residual byproducts. This technology ensures rapid inactivation of bacteria, viruses, and protozoa with minimal energy consumption and precise dose control.

Efficacy Against Waterborne Pathogens

Chlorination effectively inactivates a broad spectrum of waterborne pathogens, including bacteria, viruses, and protozoa, by disrupting their cellular processes through oxidative damage. UV-C LED disinfection offers a targeted approach by emitting ultraviolet light at specific wavelengths that disrupt the DNA and RNA of microbes, preventing replication and ensuring rapid pathogen inactivation. Both methods demonstrate high efficacy, but UV-C LEDs provide chemical-free treatment with minimal formation of harmful by-products, making them ideal for sensitive water systems.

Health and Environmental Impacts

Chlorination effectively kills pathogens but can produce harmful disinfection byproducts like trihalomethanes, posing health risks and contaminating aquatic ecosystems. UV-C LED disinfection inactivates microorganisms without chemical residues, reducing toxic effects on human health and minimizing environmental pollution. Both methods ensure water safety, but UV-C LED offers a greener alternative with lower long-term ecological impact.

Operational Costs and Maintenance

Chlorination involves continuous chemical supply and frequent monitoring, leading to higher operational costs and maintenance complexity due to handling hazardous materials and byproduct management. UV-C LED disinfection offers lower operational expenses with minimal maintenance, as it requires only periodic LED replacements without chemical storage or handling. The energy efficiency and extended lifespan of UV-C LEDs contribute to reduced long-term costs compared to traditional chlorination systems.

Regulatory Standards and Compliance

Chlorination remains widely accepted under EPA and WHO regulatory standards for water disinfection, ensuring compliance through established residual disinfectant levels and microbial reduction benchmarks. UV-C LED disinfection is gaining regulatory recognition with NSF/ANSI Standard 55 certification, emphasizing pathogen inactivation without chemical byproducts, though it often requires combined use with residual disinfectants to meet drinking water regulations fully. Regulatory frameworks prioritize consistent disinfection efficacy, validated dosing, and safety compliance, making chlorination a robust choice while UV-C LED offers a chemical-free alternative suitable for specific applications within regulatory constraints.

Future Trends in Water Disinfection Technologies

Emerging trends in water disinfection highlight the increasing adoption of UV-C LED technology due to its energy efficiency, longer lifespan, and absence of harmful byproducts compared to traditional chlorination. Innovations in UV-C LED systems emphasize precise wavelength targeting that effectively inactivates pathogens while reducing chemical reliance. Integration with smart sensors and IoT platforms enhances monitoring and control, signaling a shift toward sustainable, real-time water treatment solutions.

Related Important Terms

Photolytic Degradation

Chlorination effectively kills pathogens by releasing chlorine compounds but can produce harmful disinfection byproducts, while UV-C LED disinfection employs photolytic degradation to break down microbial DNA without chemical residues. UV-C LED technology offers targeted photolytic degradation, ensuring rapid inactivation of bacteria and viruses in water without altering its chemical composition.

Advanced Oxidation Processes (AOPs)

Advanced Oxidation Processes (AOPs) utilize reactive oxygen species to achieve superior water disinfection compared to traditional chlorination, effectively degrading organic contaminants and inactivating pathogens. UV-C LED disinfection combined with AOPs enhances microbial inactivation and reduces harmful disinfection byproducts, offering a sustainable alternative for water treatment.

Contact Time Efficiency

Chlorination requires longer contact time, typically 30 minutes, to effectively eliminate pathogens, whereas UV-C LED disinfection achieves rapid microbial inactivation within seconds to minutes due to its high-intensity ultraviolet light. UV-C LED systems offer higher contact time efficiency, enabling faster water treatment and reduced waiting periods compared to traditional chlorination methods.

Photoreactivation Resistance

Chlorination effectively inactivates a broad spectrum of pathogens but is vulnerable to photoreactivation, a process where some microorganisms repair UV-induced DNA damage upon exposure to visible light, reducing disinfection efficacy. UV-C LED disinfection provides superior photoreactivation resistance by causing irreversible DNA damage without relying on chemical agents, ensuring sustained microbial inactivation even under light exposure.

Combined UV-C/Chlorine Treatment

Combined UV-C/Chlorine treatment enhances water disinfection by leveraging UV-C LED's ability to inactivate a broad spectrum of pathogens while chlorine provides residual disinfection in the distribution system. This hybrid approach reduces chlorine dosage, minimizes harmful disinfection byproducts, and improves overall water quality and safety.

Biofilm Inactivation Rate

Chlorination achieves biofilm inactivation rates typically between 60% and 80%, effectively disrupting microbial colonies but often leaving residual chlorine by-products. UV-C LED disinfection demonstrates biofilm inactivation rates exceeding 90%, offering rapid microbial eradication without chemical residues and enhanced control over resistant biofilm formations.

By-product Minimization

Chlorination in water treatment commonly produces disinfection by-products (DBPs) such as trihalomethanes and haloacetic acids, which pose health risks and require careful monitoring. UV-C LED disinfection effectively inactivates pathogens without forming harmful DBPs, offering a safer alternative for minimizing chemical residues in potable water.

Residual-Free Disinfection

UV-C LED disinfection provides a residual-free method for water treatment, eliminating harmful byproducts and chemical residues often associated with chlorination. This technology ensures effective pathogen inactivation without altering water taste or producing toxic disinfection byproducts, making it ideal for safe, eco-friendly water purification.

Real-Time UV-C Dose Monitoring

Real-time UV-C dose monitoring ensures precise control of UV-C LED disinfection, maximizing pathogen inactivation while minimizing energy consumption and preventing under- or overexposure. Chlorination relies on residual chemical disinfectants but lacks instantaneous dose feedback, potentially leading to inconsistent microbial control and formation of harmful disinfection byproducts.

Microbial Regrowth Suppression

Chlorination effectively kills pathogens but may allow microbial regrowth due to residual disinfectant decay and formation of disinfection byproducts, whereas UV-C LED disinfection inactivates microorganisms through DNA disruption without residual chemicals, reducing post-treatment regrowth risks. Studies show UV-C LED systems provide rapid, targeted microbial suppression ideal for sensitive water applications demanding minimal byproduct formation and enhanced water safety.

Chlorination vs UV-C LED Disinfection Infographic

industrydif.com

industrydif.com