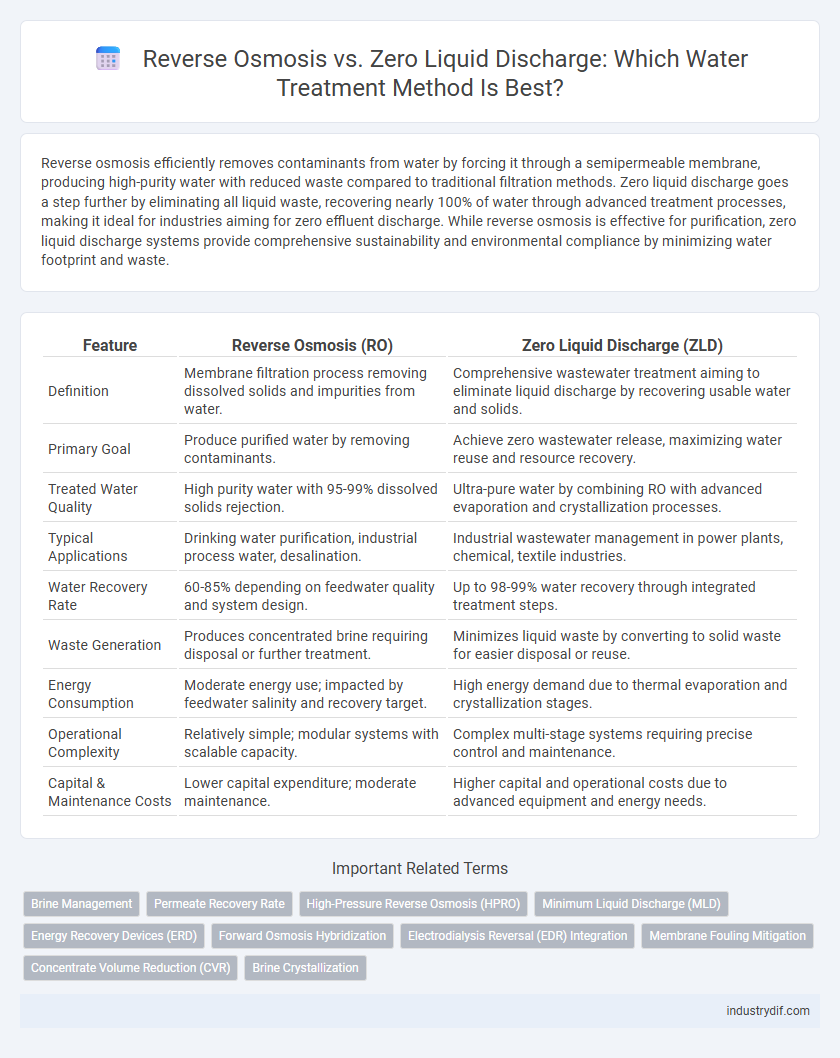

Reverse osmosis efficiently removes contaminants from water by forcing it through a semipermeable membrane, producing high-purity water with reduced waste compared to traditional filtration methods. Zero liquid discharge goes a step further by eliminating all liquid waste, recovering nearly 100% of water through advanced treatment processes, making it ideal for industries aiming for zero effluent discharge. While reverse osmosis is effective for purification, zero liquid discharge systems provide comprehensive sustainability and environmental compliance by minimizing water footprint and waste.

Table of Comparison

| Feature | Reverse Osmosis (RO) | Zero Liquid Discharge (ZLD) |

|---|---|---|

| Definition | Membrane filtration process removing dissolved solids and impurities from water. | Comprehensive wastewater treatment aiming to eliminate liquid discharge by recovering usable water and solids. |

| Primary Goal | Produce purified water by removing contaminants. | Achieve zero wastewater release, maximizing water reuse and resource recovery. |

| Treated Water Quality | High purity water with 95-99% dissolved solids rejection. | Ultra-pure water by combining RO with advanced evaporation and crystallization processes. |

| Typical Applications | Drinking water purification, industrial process water, desalination. | Industrial wastewater management in power plants, chemical, textile industries. |

| Water Recovery Rate | 60-85% depending on feedwater quality and system design. | Up to 98-99% water recovery through integrated treatment steps. |

| Waste Generation | Produces concentrated brine requiring disposal or further treatment. | Minimizes liquid waste by converting to solid waste for easier disposal or reuse. |

| Energy Consumption | Moderate energy use; impacted by feedwater salinity and recovery target. | High energy demand due to thermal evaporation and crystallization stages. |

| Operational Complexity | Relatively simple; modular systems with scalable capacity. | Complex multi-stage systems requiring precise control and maintenance. |

| Capital & Maintenance Costs | Lower capital expenditure; moderate maintenance. | Higher capital and operational costs due to advanced equipment and energy needs. |

Introduction to Reverse Osmosis (RO) and Zero Liquid Discharge (ZLD)

Reverse Osmosis (RO) is a water purification technology that uses a semipermeable membrane to remove ions, molecules, and larger particles from drinking water, effectively reducing contaminants such as salts and organic matter. Zero Liquid Discharge (ZLD) is an advanced wastewater treatment process designed to eliminate all liquid waste by recovering and recycling treated water, leaving behind solid residues. Both RO and ZLD play critical roles in sustainable water management by optimizing water reuse and minimizing environmental discharge.

Fundamental Principles: How RO and ZLD Work

Reverse Osmosis (RO) operates by applying pressure to force water through a semipermeable membrane that blocks contaminants, allowing only purified water to pass through. Zero Liquid Discharge (ZLD) combines multiple processes, such as evaporation and crystallization, to recover nearly all water and convert wastewater into solid waste, achieving minimal to zero liquid effluent. RO focuses on filtration and membrane technology, whereas ZLD emphasizes complete water recovery and waste minimization through thermal and chemical methods.

Key Applications in Industrial Water Treatment

Reverse osmosis (RO) is primarily used for desalination and removal of dissolved solids in industries such as pharmaceuticals, food and beverage, and power generation, ensuring high-quality process water and reducing contaminants. Zero liquid discharge (ZLD) systems are employed in sectors with zero wastewater discharge policies like textiles, chemicals, and petrochemicals, recovering nearly all water and converting waste into solid residues. Both technologies play crucial roles in optimizing water reuse, minimizing environmental impact, and complying with stringent industrial discharge regulations.

Efficiency Comparison: Water Recovery Rates

Reverse Osmosis systems typically achieve water recovery rates between 50% to 85%, depending on feedwater quality and membrane technology. Zero Liquid Discharge processes can recover up to 95% or more of water by integrating multiple treatment stages like evaporation and crystallization. RO offers faster turnaround with moderate recovery, while ZLD maximizes water reuse at higher energy and operational complexity.

Environmental Impact: Minimizing Discharge and Waste

Reverse osmosis (RO) effectively reduces contaminants by filtering water through semipermeable membranes, producing concentrated brine as waste that can negatively impact marine ecosystems if not properly managed. Zero Liquid Discharge (ZLD) systems aim to eliminate all liquid waste by recovering nearly 100% of water through evaporation and crystallization, significantly minimizing environmental discharge and reducing the risk of groundwater contamination. Implementing ZLD technology often results in higher energy consumption but offers superior environmental protection by converting waste into solid residues suitable for safe disposal or reuse.

Operational Costs and Economic Considerations

Reverse osmosis systems typically incur lower initial capital costs but higher ongoing operational expenses due to energy-intensive membrane filtration and frequent membrane replacement. Zero liquid discharge (ZLD) processes demand significant upfront investment and complex infrastructure, yet result in minimal wastewater discharge and reduced environmental compliance costs over time. Evaluating the total cost of ownership, including energy consumption, maintenance, and regulatory fees, is crucial for determining the most economically viable water treatment solution.

System Design and Infrastructure Requirements

Reverse osmosis systems rely on high-pressure pumps, semi-permeable membranes, and pre-treatment units to remove contaminants from water, requiring significant energy input and regular maintenance for membrane longevity. Zero Liquid Discharge (ZLD) systems incorporate advanced evaporation and crystallization units alongside pretreatment and RO stages to eliminate all liquid waste, demanding extensive infrastructure, higher capital investment, and complex operational controls. While RO prioritizes efficient contaminant removal with simpler setup, ZLD emphasizes complete waste elimination through integrated, large-scale system designs that necessitate robust mechanical and thermal components.

Challenges and Limitations of RO vs ZLD

Reverse Osmosis (RO) faces challenges such as high energy consumption, membrane fouling, and limited capability to handle high-salinity wastewater, which restricts its efficiency and lifespan. Zero Liquid Discharge (ZLD) systems, while more effective in minimizing liquid waste, encounter limitations including significant operational costs, complex maintenance, and the requirement for specialized infrastructure to recover solids and manage brine concentrate. RO is typically more suitable for moderate contamination levels, whereas ZLD is essential for industries with stringent environmental discharge regulations but demands higher capital investment and technical expertise.

Regulatory Compliance in Water Management

Reverse osmosis systems effectively reduce contaminants to meet stringent drinking water standards, ensuring compliance with regulations such as the Safe Drinking Water Act (SDWA). Zero Liquid Discharge (ZLD) technology advances regulatory adherence by minimizing wastewater discharge and facilitating recovery of reusable water, aligning with EPA effluent guidelines. Both methods support sustainable water management practices by addressing environmental compliance requirements and reducing the impact of industrial effluents on water bodies.

Future Trends in RO and ZLD Technologies

Future trends in Reverse Osmosis (RO) technology focus on enhancing energy efficiency and membrane durability through advanced nanomaterials and smart monitoring systems. Zero Liquid Discharge (ZLD) innovations prioritize integrating renewable energy sources and wastewater recovery techniques to achieve sustainable water reuse. The convergence of RO and ZLD is driving hybrid systems that optimize resource recovery while minimizing environmental impact in industrial water treatment.

Related Important Terms

Brine Management

Reverse osmosis generates concentrated brine as a byproduct requiring effective brine management to prevent environmental pollution. Zero Liquid Discharge systems treat and recycle brine, converting it into solid waste and minimizing liquid waste discharge, offering a sustainable solution for industrial water management.

Permeate Recovery Rate

Reverse osmosis systems typically achieve a permeate recovery rate of 75-85%, efficiently converting feed water into purified output while discarding concentrated brine. Zero liquid discharge systems push recovery rates closer to 95-99%, employing advanced treatment and evaporation techniques to minimize liquid waste and maximize water reuse.

High-Pressure Reverse Osmosis (HPRO)

High-Pressure Reverse Osmosis (HPRO) utilizes pressures above 600 psi to enhance water recovery efficiency and reduce waste brine volume, making it a cost-effective alternative to Zero Liquid Discharge (ZLD) systems in industrial wastewater treatment. While ZLD aims for complete water reuse by evaporating all liquid waste, HPRO balances operational costs with substantial contaminant rejection, especially for desalination and brackish water applications.

Minimum Liquid Discharge (MLD)

Reverse osmosis (RO) efficiently reduces contaminants by forcing water through a semipermeable membrane, achieving high-purity water recovery but still generating a brine concentrate requiring disposal. Zero Liquid Discharge (ZLD) systems incorporate RO with advanced evaporation and crystallization techniques, enabling Minimum Liquid Discharge (MLD) by recovering nearly all water and minimizing wastewater to solid residues for zero environmental liquid effluent.

Energy Recovery Devices (ERD)

Energy Recovery Devices (ERD) significantly enhance the efficiency of Reverse Osmosis (RO) systems by capturing and reusing hydraulic energy from the high-pressure brine stream, reducing overall energy consumption by up to 60%. Zero Liquid Discharge (ZLD) systems, while comprehensive in minimizing liquid waste, typically rely on multiple energy-intensive steps where ERDs have limited application, resulting in higher energy demands compared to RO with ERD integration.

Forward Osmosis Hybridization

Forward osmosis hybridization integrates reverse osmosis with zero liquid discharge systems to enhance water recovery efficiency while minimizing brine production. This approach leverages osmotic pressure gradients in forward osmosis membranes to pretreat feedwater, reducing fouling and energy consumption compared to standalone reverse osmosis processes.

Electrodialysis Reversal (EDR) Integration

Reverse osmosis efficiently removes dissolved salts and contaminants from water, while zero liquid discharge systems aim to eliminate all liquid waste by integrating multiple treatment technologies. The integration of Electrodialysis Reversal (EDR) with reverse osmosis in zero liquid discharge systems enhances ion removal efficiency, reduces scaling, and lowers energy consumption by periodically reversing polarity to prevent membrane fouling.

Membrane Fouling Mitigation

Reverse osmosis employs semi-permeable membranes to filter contaminants, where membrane fouling mitigation is achieved through pretreatment processes such as chemical dosing and periodic membrane cleaning to maintain flux and prolong membrane life. Zero liquid discharge systems integrate advanced filtration and evaporation technologies, combining reverse osmosis with additional stages like crystallization, effectively minimizing membrane fouling by reducing the volume and concentration of harmful solids.

Concentrate Volume Reduction (CVR)

Reverse osmosis systems typically achieve a concentrate volume reduction (CVR) of 70-85%, efficiently reducing wastewater but still producing a significant brine stream requiring disposal. Zero liquid discharge (ZLD) technologies maximize CVR by recovering nearly 100% of water, converting all liquid waste into solid residues, thereby eliminating liquid discharge and minimizing environmental impact.

Brine Crystallization

Reverse osmosis effectively reduces contaminants by pushing water through a semipermeable membrane, producing concentrated brine that requires further management, whereas zero liquid discharge systems integrate brine crystallization to recover solid salts and eliminate liquid waste entirely. Brine crystallization in ZLD systems transforms the concentrated brine from reverse osmosis into recoverable salt crystals, achieving near-zero wastewater discharge and enhancing sustainable water recovery.

Reverse Osmosis vs Zero Liquid Discharge Infographic

industrydif.com

industrydif.com