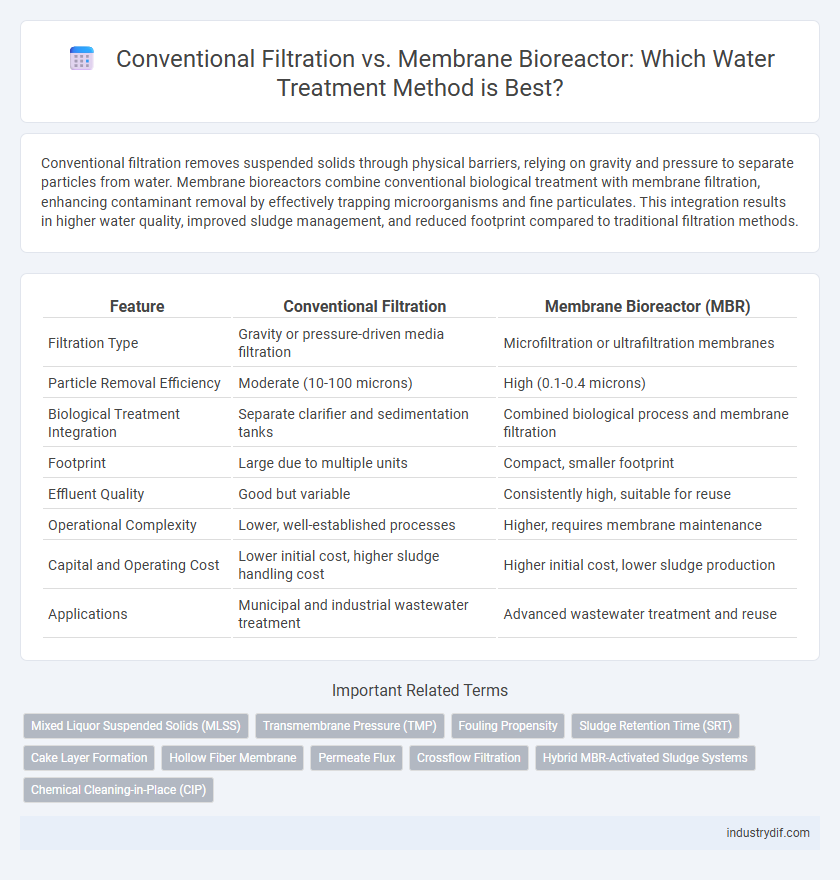

Conventional filtration removes suspended solids through physical barriers, relying on gravity and pressure to separate particles from water. Membrane bioreactors combine conventional biological treatment with membrane filtration, enhancing contaminant removal by effectively trapping microorganisms and fine particulates. This integration results in higher water quality, improved sludge management, and reduced footprint compared to traditional filtration methods.

Table of Comparison

| Feature | Conventional Filtration | Membrane Bioreactor (MBR) |

|---|---|---|

| Filtration Type | Gravity or pressure-driven media filtration | Microfiltration or ultrafiltration membranes |

| Particle Removal Efficiency | Moderate (10-100 microns) | High (0.1-0.4 microns) |

| Biological Treatment Integration | Separate clarifier and sedimentation tanks | Combined biological process and membrane filtration |

| Footprint | Large due to multiple units | Compact, smaller footprint |

| Effluent Quality | Good but variable | Consistently high, suitable for reuse |

| Operational Complexity | Lower, well-established processes | Higher, requires membrane maintenance |

| Capital and Operating Cost | Lower initial cost, higher sludge handling cost | Higher initial cost, lower sludge production |

| Applications | Municipal and industrial wastewater treatment | Advanced wastewater treatment and reuse |

Overview of Conventional Filtration in Water Treatment

Conventional filtration in water treatment involves the use of granular media filters such as sand or anthracite to remove suspended solids and particulate matter. This method relies on physical straining, sedimentation, and biological processes to improve water clarity and reduce turbidity. While effective for basic contaminant removal, conventional filtration has limitations in eliminating dissolved organic compounds and pathogens compared to advanced membrane bioreactor (MBR) systems.

Introduction to Membrane Bioreactor (MBR) Technology

Membrane Bioreactor (MBR) technology integrates conventional biological treatment with membrane filtration, enhancing wastewater treatment efficiency by effectively removing suspended solids and microorganisms. Unlike traditional filtration, MBR uses microfiltration or ultrafiltration membranes to provide higher quality effluent, allowing for reduced footprint and improved process control. This technology is widely adopted in municipal and industrial applications for superior removal of organic contaminants, nitrogen, and phosphorus.

Key Differences Between Conventional Filtration and MBR

Conventional filtration relies on physical barriers such as sand or gravel to remove suspended solids, while Membrane Bioreactor (MBR) systems incorporate advanced microfiltration or ultrafiltration membranes for superior solid-liquid separation. MBR technology offers higher effluent quality, smaller footprint, and better nutrient removal compared to traditional filtration methods. Operational complexity and energy consumption are generally higher in MBR systems due to the need for membrane aeration and cleaning protocols.

Process Flow: Conventional Filtration vs. MBR

Conventional filtration typically involves sequential processes such as coagulation, flocculation, sedimentation, and sand filtration to remove suspended solids, followed by disinfection for microbial control. Membrane bioreactors (MBRs) integrate biological treatment with membrane filtration, combining activated sludge processes with ultrafiltration or microfiltration membranes for enhanced solid-liquid separation and higher effluent quality. The MBR process flow offers a compact footprint, reduced sludge production, and superior removal of pathogens and micropollutants compared to conventional filtration systems.

Removal Efficiency: Suspended Solids and Contaminants

Conventional filtration effectively removes larger suspended solids but often struggles with fine contaminants and dissolved pollutants. Membrane bioreactors (MBRs) offer superior removal efficiency, capturing particles as small as 0.1 microns, including bacteria, viruses, and organic compounds. This advanced technology results in higher quality effluent suitable for reuse and stringent discharge standards.

Operational Costs and Energy Consumption Comparison

Conventional filtration systems typically incur lower initial operational costs but require frequent maintenance due to filter clogging, leading to higher long-term expenses. Membrane bioreactors (MBRs) have higher energy consumption driven by aeration and membrane cleaning processes, yet they offer enhanced water recovery rates and reduced chemical usage, which can offset operational costs over time. Energy efficiency in MBRs is improving with advances in membrane technology, making them more competitive compared to traditional filtration methods.

Footprint and Infrastructure Requirements

Conventional filtration systems typically require larger footprints and extensive infrastructure due to gravity-based settling tanks and multiple filtration stages, demanding substantial land and structural support. Membrane Bioreactor (MBR) technology combines biological treatment with membrane filtration in a compact unit, significantly reducing the footprint by eliminating the need for large clarifiers and secondary sedimentation tanks. The modular design of MBR systems allows for easier integration into existing facilities and lower infrastructure costs, making them ideal for space-constrained urban environments.

Maintenance and Lifespan Considerations

Conventional filtration systems typically require frequent media replacement and routine backwashing, resulting in higher maintenance efforts and shorter operational lifespans of 5 to 7 years. Membrane Bioreactors (MBRs) offer extended lifespan up to 10 to 15 years due to advanced membrane technology, although membrane fouling necessitates periodic chemical cleaning and careful operational monitoring. Effective maintenance protocols for MBRs ensure prolonged performance with reduced downtime compared to traditional filtration methods.

Applications: Municipal and Industrial Use Cases

Conventional filtration systems are widely used in municipal water treatment for removing suspended solids and reducing turbidity, providing effective pretreatment for large-scale water supply networks. Membrane bioreactors (MBRs) offer advanced wastewater treatment solutions in both municipal and industrial sectors, efficiently removing organic contaminants, nutrients, and pathogens with a smaller footprint. MBR technology is increasingly preferred in pharmaceutical, food processing, and chemical industries due to its ability to produce high-quality effluent suitable for reuse and discharge compliance.

Future Trends in Filtration and Bioreactor Technologies

Future trends in water treatment emphasize the integration of advanced membrane bioreactors (MBRs) with conventional filtration methods to enhance efficiency and scalability. Innovations in nanofiltration and ultrafiltration membranes combined with aerobic and anaerobic biological processes are driving significant improvements in contaminant removal and energy consumption. Emerging technologies prioritize sustainable operation, real-time monitoring, and automated control systems to optimize water reuse and reduce environmental impact.

Related Important Terms

Mixed Liquor Suspended Solids (MLSS)

Conventional filtration systems typically handle Mixed Liquor Suspended Solids (MLSS) at concentrations of 2,000 to 4,000 mg/L, whereas Membrane Bioreactors (MBRs) operate efficiently at much higher MLSS levels, often between 8,000 and 12,000 mg/L. Higher MLSS concentrations in MBRs enhance biomass retention and treatment capacity, resulting in improved effluent quality and reduced sludge production.

Transmembrane Pressure (TMP)

Transmembrane Pressure (TMP) in Conventional Filtration systems typically ranges from 0.1 to 0.3 bar, indicating lower resistance but limited filtration efficiency compared to Membrane Bioreactors (MBRs), where TMP can rise to 0.5 to 2 bar due to membrane fouling and biofilm accumulation. Monitoring TMP in MBRs is critical for optimizing operational performance and cleaning cycles, as elevated TMP directly impacts energy consumption and permeate quality.

Fouling Propensity

Conventional filtration systems experience higher fouling propensity due to larger pore sizes and accumulation of suspended solids, leading to frequent maintenance and reduced efficiency. Membrane Bioreactor (MBR) technology offers lower fouling rates by utilizing fine membrane pores and biological degradation, enhancing water treatment performance and operational stability.

Sludge Retention Time (SRT)

Conventional filtration systems typically operate with shorter Sludge Retention Times (SRT), leading to less efficient microbial degradation and higher sludge production. Membrane bioreactor (MBR) technology allows for extended SRTs, enhancing biomass concentration and improving overall treatment performance through effective sludge retention.

Cake Layer Formation

Conventional filtration relies on a cake layer formed by particulate matter trapped on the filter surface, which increases resistance and reduces flow rate over time. Membrane bioreactors minimize cake layer formation through fine membrane pores and controlled biomass concentration, enhancing filtration efficiency and prolonging membrane lifespan.

Hollow Fiber Membrane

Hollow fiber membranes in membrane bioreactors (MBRs) offer superior filtration by combining biological treatment with physical separation, enabling high-quality effluent with lower footprint compared to conventional filtration methods. These membranes provide enhanced removal of suspended solids and pathogens due to their fine pore size and effective backwashing capabilities, resulting in more reliable wastewater treatment performance.

Permeate Flux

Conventional filtration systems typically exhibit lower permeate flux rates due to larger pore sizes and less efficient contaminant separation, often limiting throughput and increasing operational demands. Membrane bioreactors achieve higher permeate flux by combining biological treatment with fine membrane filtration, enhancing water recovery and improving effluent quality with consistent performance under varying loads.

Crossflow Filtration

Crossflow filtration in membrane bioreactors (MBRs) enhances water treatment efficiency by continuously sweeping membranes, reducing fouling and enabling higher flux rates compared to conventional filtration methods that rely on dead-end flow. This dynamic filtration mechanism extends membrane lifespan and ensures consistent permeate quality by maintaining optimal solids separation and minimizing cake layer formation.

Hybrid MBR-Activated Sludge Systems

Hybrid MBR-Activated Sludge Systems combine conventional activated sludge processes with membrane bioreactors, enhancing organic matter removal and reducing sludge production while maintaining high effluent quality. This integration leverages membrane filtration's fine separation mechanism and the activated sludge system's biological degradation, resulting in improved treatment efficiency and compact plant design.

Chemical Cleaning-in-Place (CIP)

Chemical Cleaning-in-Place (CIP) is essential for maintaining optimal performance in both conventional filtration and membrane bioreactor (MBR) systems, with MBRs requiring more frequent and specialized CIP protocols due to membrane fouling. Effective CIP solutions target biofilm and scaling in MBRs, ensuring prolonged membrane lifespan and consistent permeate quality compared to conventional filtration.

Conventional Filtration vs Membrane Bioreactor Infographic

industrydif.com

industrydif.com