Desalination removes salts and impurities from seawater to produce potable water using processes like reverse osmosis or thermal distillation. Electrochemical water splitting generates hydrogen and oxygen gases by applying an electric current to water, representing a method for clean energy production rather than potable water creation. While desalination directly addresses freshwater scarcity, electrochemical water splitting primarily supports renewable energy storage and hydrogen fuel generation.

Table of Comparison

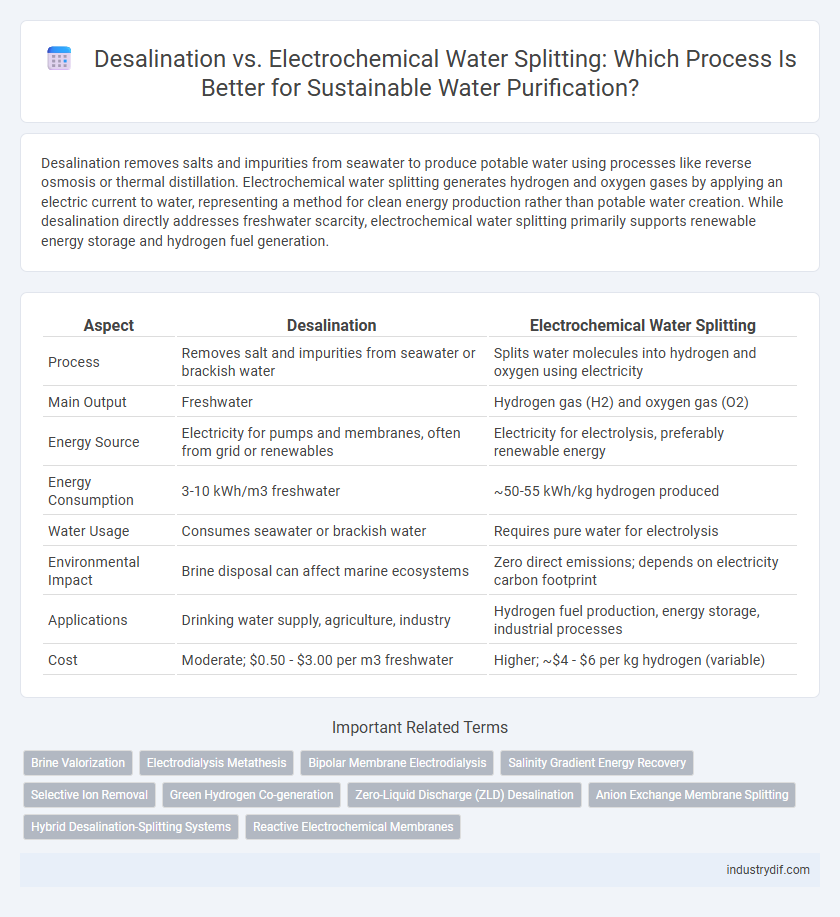

| Aspect | Desalination | Electrochemical Water Splitting |

|---|---|---|

| Process | Removes salt and impurities from seawater or brackish water | Splits water molecules into hydrogen and oxygen using electricity |

| Main Output | Freshwater | Hydrogen gas (H2) and oxygen gas (O2) |

| Energy Source | Electricity for pumps and membranes, often from grid or renewables | Electricity for electrolysis, preferably renewable energy |

| Energy Consumption | 3-10 kWh/m3 freshwater | ~50-55 kWh/kg hydrogen produced |

| Water Usage | Consumes seawater or brackish water | Requires pure water for electrolysis |

| Environmental Impact | Brine disposal can affect marine ecosystems | Zero direct emissions; depends on electricity carbon footprint |

| Applications | Drinking water supply, agriculture, industry | Hydrogen fuel production, energy storage, industrial processes |

| Cost | Moderate; $0.50 - $3.00 per m3 freshwater | Higher; ~$4 - $6 per kg hydrogen (variable) |

Introduction to Water Treatment Technologies

Desalination involves removing salts and impurities from seawater to produce freshwater, primarily using reverse osmosis or thermal methods. Electrochemical water splitting generates hydrogen and oxygen by applying an electric current to water, offering a clean energy source while addressing water purification. Both technologies play vital roles in advancing water treatment solutions to meet increasing global demand for clean and sustainable water resources.

Defining Desalination: Methods and Applications

Desalination is the process of removing dissolved salts and impurities from seawater or brackish water to produce fresh drinking water, primarily using methods like reverse osmosis, multi-stage flash distillation, and electrodialysis. This technology is essential for providing potable water in arid regions and areas with limited freshwater resources, supporting agriculture, industry, and municipal needs. Advances in membrane technology and energy-efficient systems continue to expand the applications and cost-effectiveness of desalination worldwide.

Understanding Electrochemical Water Splitting

Electrochemical water splitting uses an electric current to separate water molecules into hydrogen and oxygen gases, offering a clean method for producing hydrogen fuel without carbon emissions. This process relies on catalysts like platinum or transition metal oxides to enhance efficiency and reduce energy consumption during electrolysis. Unlike desalination, which removes salt and impurities from seawater to produce potable water, electrochemical water splitting focuses on generating renewable energy carriers, making it critical for sustainable energy systems.

Energy Requirements: Desalination vs Water Splitting

Desalination processes, especially reverse osmosis, typically consume around 3 to 4 kWh per cubic meter of freshwater produced, leveraging pressure-driven membrane filtration to remove salts efficiently. Electrochemical water splitting, used to generate hydrogen, demands significantly higher energy input, averaging 39.4 kWh per kilogram of hydrogen, equivalent to approximately 9 kWh to produce one cubic meter of hydrogen gas. Energy consumption in water splitting is influenced by electrode materials and electrolyzer efficiency, whereas desalination energy demand is closely tied to feedwater salinity and recovery rates.

Industrial Scalability and Infrastructure

Desalination technology leverages established large-scale reverse osmosis and thermal processes, supported by extensive coastal infrastructure, enabling reliable industrial scalability for freshwater production. Electrochemical water splitting, though promising for green hydrogen and oxygen generation, faces challenges in scaling due to high energy demands, costly catalysts, and limited infrastructure for widespread deployment. Industrial applications prioritize desalination for immediate water needs while ongoing research targets improving electrochemical methods for future sustainable water resource management.

Purity and Quality of Produced Water

Desalination processes, particularly reverse osmosis, deliver high-purity potable water by effectively removing salts, minerals, and contaminants, achieving total dissolved solids (TDS) levels typically below 500 mg/L. Electrochemical water splitting primarily produces hydrogen and oxygen gases, with the purity of resultant water largely dependent on the feedwater quality since impurities remain unless further treated. The water from desalination is directly suitable for drinking and industrial applications, whereas water from electrochemical water splitting often requires additional purification to meet potable standards.

Environmental Impact and Sustainability

Desalination processes often demand significant energy consumption and produce brine byproducts that can harm marine ecosystems, posing challenges to environmental sustainability. In contrast, electrochemical water splitting harnesses renewable energy to generate hydrogen and oxygen, offering a cleaner alternative with minimal ecological footprint. Evaluating these technologies requires balancing energy efficiency, resource use, and long-term environmental impacts to promote sustainable water management solutions.

Economic Considerations and Cost Analysis

Desalination techniques, particularly reverse osmosis, present lower operational costs compared to electrochemical water splitting due to mature technology and high water output efficiency. Electrochemical water splitting, while promising for hydrogen production, involves high energy consumption and expensive catalysts, increasing overall expenses. Cost analysis highlights that desalination remains more feasible for large-scale potable water production, whereas electrochemical methods are economically viable primarily for niche applications in hydrogen fuel generation.

Current Challenges and Technological Innovations

Desalination faces challenges such as high energy consumption and membrane fouling, driving innovations like graphene-based membranes and energy recovery devices to improve efficiency. Electrochemical water splitting struggles with catalyst degradation and high overpotentials, prompting advances in nanostructured electrocatalysts and renewable energy integration to enhance hydrogen production. Both technologies benefit from hybrid systems and AI-driven process optimization to address scalability and environmental impact concerns.

Future Prospects in Water Processing Technologies

Desalination technologies, such as reverse osmosis and multi-stage flash distillation, continue to advance with improved energy efficiency and reduced environmental impact, making them crucial for addressing global freshwater scarcity. Electrochemical water splitting, leveraging renewable energy sources to produce hydrogen and oxygen, presents a promising future for sustainable water processing by enabling clean energy integration and resource recovery. The convergence of these technologies with smart sensor networks and AI-driven optimization systems will likely transform water treatment, enhancing scalability and operational resilience in diverse environments.

Related Important Terms

Brine Valorization

Desalination produces large volumes of brine rich in salts and minerals, enabling brine valorization through recovery of valuable compounds such as lithium, magnesium, and bromine to enhance resource efficiency. Electrochemical water splitting generates less concentrated brine and allows simultaneous hydrogen production, yet faces challenges in brine valorization due to dilute by-products and complex extraction processes.

Electrodialysis Metathesis

Electrodialysis Metathesis (EDM) offers energy-efficient desalination by selectively removing ions through ion-exchange membranes, outperforming traditional thermal desalination methods in salt removal and water recovery rates. Compared to electrochemical water splitting, EDM focuses on ion separation without producing hydrogen gas, making it ideal for sustainable freshwater production and brine management.

Bipolar Membrane Electrodialysis

Bipolar Membrane Electrodialysis (BMED) offers a sustainable approach for desalination by efficiently separating ions and generating acid and base without harmful byproducts, improving water purification compared to traditional desalination methods. Electrochemical water splitting focuses on hydrogen production but integrating BMED enhances ion separation and energy efficiency in treating saline water, positioning it as a promising technology for advanced water treatment and resource recovery.

Salinity Gradient Energy Recovery

Desalination effectively removes salts from seawater but often wastes the salinity gradient energy present between freshwater and seawater, whereas electrochemical water splitting can harness this energy by using salinity gradients to improve hydrogen production efficiency. Integrating salinity gradient energy recovery in electrochemical water splitting systems enhances renewable hydrogen generation while reducing the environmental impacts and energy consumption associated with conventional desalination processes.

Selective Ion Removal

Desalination selectively removes salts and impurities from seawater through processes like reverse osmosis and membrane distillation, effectively providing potable water by targeting ions such as sodium and chloride. Electrochemical water splitting, using ion-selective electrodes, enables precise ion removal and separation by applying electric fields to selectively transport specific ions, offering advanced control in water purification and resource recovery.

Green Hydrogen Co-generation

Desalination processes remove salts and impurities from seawater to produce fresh water, while electrochemical water splitting uses renewable energy to generate green hydrogen and oxygen through hydrogen co-generation. Combining desalination with water splitting technologies enhances sustainable water management and clean energy production by utilizing brine and renewable electricity efficiently.

Zero-Liquid Discharge (ZLD) Desalination

Zero-Liquid Discharge (ZLD) desalination employs advanced membrane filtration and thermal processes to achieve complete reclamation of water while minimizing brine waste, making it ideal for sustainable water management in arid regions. Electrochemical water splitting, primarily used for hydrogen production, generates oxygen and hydrogen gases without wastewater, but does not address liquid waste recovery or salt concentration challenges inherent in desalination.

Anion Exchange Membrane Splitting

Anion exchange membrane (AEM) splitting offers a promising electrochemical water splitting method by selectively transporting hydroxide ions, enhancing energy efficiency compared to traditional desalination processes that rely on membrane filtration to remove salts. This technology enables simultaneous hydrogen production and water purification, making it a sustainable alternative to conventional desalination techniques with higher operational costs and energy consumption.

Hybrid Desalination-Splitting Systems

Hybrid desalination-splitting systems integrate reverse osmosis membranes with electrochemical water splitting cells to simultaneously produce fresh water and hydrogen fuel, enhancing energy efficiency and reducing overall operational costs. These systems optimize brine concentration gradients to improve ion transport and reduce energy consumption compared to standalone desalination or water splitting technologies.

Reactive Electrochemical Membranes

Reactive Electrochemical Membranes (REMs) enhance water purification by combining advanced oxidation processes with membrane filtration, offering higher efficiency in removing contaminants compared to traditional desalination methods. REMs operate by generating reactive species electrochemically, which degrade organic pollutants and reduce membrane fouling, making them a promising technology for sustainable and energy-efficient water treatment.

Desalination vs Electrochemical Water Splitting Infographic

industrydif.com

industrydif.com