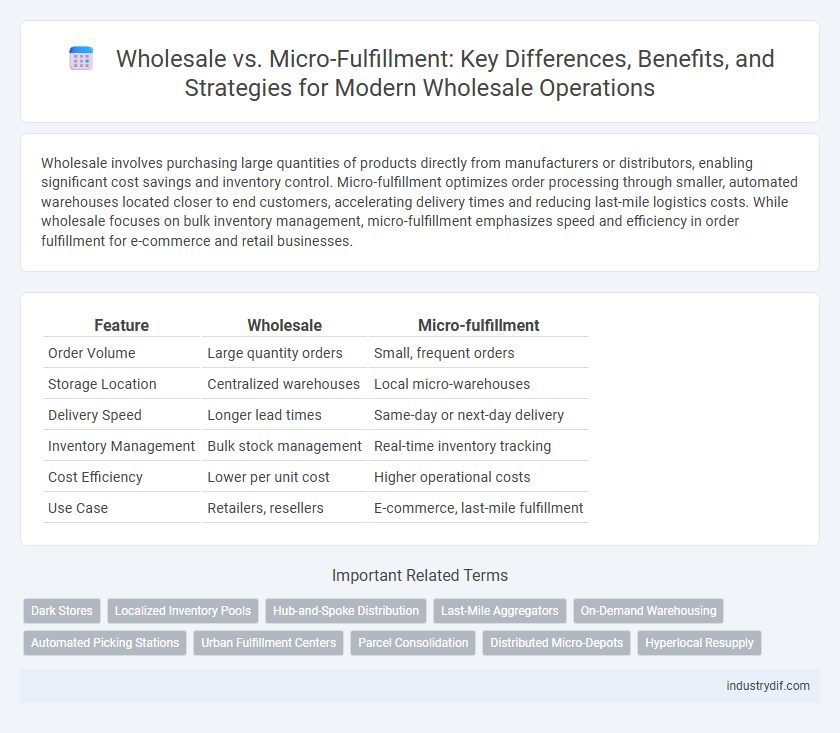

Wholesale involves purchasing large quantities of products directly from manufacturers or distributors, enabling significant cost savings and inventory control. Micro-fulfillment optimizes order processing through smaller, automated warehouses located closer to end customers, accelerating delivery times and reducing last-mile logistics costs. While wholesale focuses on bulk inventory management, micro-fulfillment emphasizes speed and efficiency in order fulfillment for e-commerce and retail businesses.

Table of Comparison

| Feature | Wholesale | Micro-fulfillment |

|---|---|---|

| Order Volume | Large quantity orders | Small, frequent orders |

| Storage Location | Centralized warehouses | Local micro-warehouses |

| Delivery Speed | Longer lead times | Same-day or next-day delivery |

| Inventory Management | Bulk stock management | Real-time inventory tracking |

| Cost Efficiency | Lower per unit cost | Higher operational costs |

| Use Case | Retailers, resellers | E-commerce, last-mile fulfillment |

Understanding Wholesale: Definition and Key Concepts

Wholesale involves the bulk sale of goods directly from manufacturers or distributors to retailers or large buyers, enabling significant cost savings through volume purchasing. Key concepts include supply chain efficiency, bulk inventory management, and price negotiation, which differentiate it from micro-fulfillment centers that focus on rapid, localized order processing. Understanding wholesale is crucial for optimizing distribution strategies and leveraging economies of scale in B2B transactions.

What is Micro-fulfillment? An Industry Overview

Micro-fulfillment refers to a highly automated, compact distribution strategy designed to expedite order processing and delivery within urban and suburban areas. This approach uses localized fulfillment centers equipped with robotics and AI to optimize inventory management, reduce transportation costs, and enhance delivery speed for retailers and wholesalers. The micro-fulfillment industry addresses evolving consumer demands for faster shipping while complementing traditional wholesale distribution models by focusing on efficiency in the last-mile delivery segment.

Comparative Analysis: Wholesale vs Micro-fulfillment Models

Wholesale models emphasize bulk purchasing and large-scale distribution, optimizing cost-efficiency for retailers and suppliers. Micro-fulfillment centers leverage automation and proximity to consumers, enhancing speed and reducing last-mile delivery costs. Comparing both, wholesale excels in inventory volume and price advantages, while micro-fulfillment prioritizes agility and customer experience in urban markets.

Inventory Management Strategies in Wholesale and Micro-fulfillment

Inventory management strategies in wholesale prioritize bulk purchasing and long-term storage to optimize cost efficiency and meet large order demands. In contrast, micro-fulfillment relies on localized, real-time inventory tracking and rapid replenishment to enhance speed and reduce holding costs. Combining wholesale scale with micro-fulfillment agility enables better stock turnover and responsiveness to fluctuating consumer demand.

Technology Integration: Wholesale and Micro-fulfillment Solutions

Wholesale and micro-fulfillment solutions leverage advanced technology integration to optimize inventory management, order processing, and distribution efficiency. Wholesale systems utilize large-scale warehouse automation and advanced ERP platforms to handle bulk orders and wide product assortments, while micro-fulfillment centers focus on localized, AI-driven robotics and real-time data analytics to expedite last-mile delivery and reduce fulfillment time. Combining IoT sensors, machine learning algorithms, and cloud computing enhances operational visibility and scalability across both wholesale and micro-fulfillment models.

Supply Chain Efficiency: Differences Between Wholesale and Micro-fulfillment

Wholesale relies on bulk inventory storage and centralized distribution centers to streamline supply chain efficiency, minimizing transportation costs through large-scale shipments. In contrast, micro-fulfillment embraces localized, small-scale fulfillment centers situated near end consumers, accelerating order processing and reducing last-mile delivery times. This decentralized approach enhances responsiveness to demand fluctuations but may increase operational complexity compared to traditional wholesale models.

Cost Implications: Wholesale vs Micro-fulfillment Operations

Wholesale operations benefit from economies of scale, significantly reducing per-unit costs through large volume purchasing and centralized distribution. Micro-fulfillment centers, while offering faster delivery, often incur higher operational expenses due to smaller inventory batches and increased labor intensity. Businesses must weigh the lower cost efficiency of wholesale against the agility and customer satisfaction benefits provided by micro-fulfillment.

Customer Experience: Meeting Demand in Wholesale and Micro-fulfillment

Wholesale leverages bulk inventory and efficient distribution centers to meet large-scale demand, ensuring consistent product availability and competitive pricing for customers. Micro-fulfillment centers, located closer to end consumers, enhance customer experience by enabling faster delivery times and greater order customization. Balancing wholesale's comprehensive stock with micro-fulfillment's speed addresses diverse customer needs in a dynamic market.

Scalability and Flexibility: Which Model Leads?

Wholesale offers unmatched scalability by handling large volumes of inventory across extensive distribution networks, enabling rapid expansion in diverse markets. Micro-fulfillment centers provide greater flexibility through localized, technology-driven operations tailored for fast, last-mile delivery and dynamic inventory management. Choosing between the two depends on balancing wholesale's capacity for mass distribution and micro-fulfillment's agility in meeting evolving consumer demands.

Future Trends: Wholesale and Micro-fulfillment in a Digital Economy

Future trends in wholesale increasingly integrate micro-fulfillment centers to enhance speed and efficiency in the digital economy. Micro-fulfillment leverages advanced automation, artificial intelligence, and real-time data analytics to optimize inventory management and reduce delivery times. This convergence enables wholesalers to meet growing consumer expectations for rapid, flexible, and localized fulfillment solutions while maintaining cost-effective bulk distribution.

Related Important Terms

Dark Stores

Dark stores, specialized fulfillment centers designed exclusively for online order processing, enable wholesalers to streamline inventory management and accelerate delivery times compared to traditional wholesale distribution. By integrating micro-fulfillment technology within dark stores, wholesale operations can achieve higher efficiency and meet increasing consumer demand for rapid e-commerce fulfillment.

Localized Inventory Pools

Wholesale distribution leverages large centralized inventory pools to optimize bulk shipments and lower per-unit costs, while micro-fulfillment prioritizes localized inventory pools in urban warehouses to enable faster delivery and enhance customer satisfaction. Localized inventory pools reduce transportation costs and improve supply chain responsiveness, crucial for meeting the increasing demand for same-day or next-day delivery in micro-fulfillment models.

Hub-and-Spoke Distribution

Hub-and-spoke distribution optimizes wholesale supply chains by centralizing inventory in a main hub and efficiently dispatching goods to multiple spokes or micro-fulfillment centers, reducing last-mile delivery costs and improving order fulfillment speed. This model contrasts with traditional wholesale by leveraging micro-fulfillment centers close to end customers, enhancing inventory turnover and responsiveness while maintaining centralized procurement advantages.

Last-Mile Aggregators

Last-mile aggregators streamline wholesale distribution by consolidating multiple orders to optimize delivery efficiency and reduce costs. Micro-fulfillment centers, in contrast, focus on localized, rapid inventory handling but often lack the broad network connectivity that wholesale last-mile aggregators provide for large-scale order aggregation and fulfillment.

On-Demand Warehousing

On-demand warehousing offers wholesale businesses flexible storage solutions that optimize inventory management compared to fixed-location micro-fulfillment centers, enabling rapid scaling and cost efficiency. This approach leverages real-time data analytics and dynamic space allocation to meet fluctuating demand without long-term commitments.

Automated Picking Stations

Automated picking stations in wholesale operations significantly enhance order accuracy and speed by utilizing robotics and AI-driven systems to streamline inventory handling and reduce manual labor. Compared to micro-fulfillment centers, wholesale facilities equipped with automated picking stations can process larger volume orders more efficiently, supporting high-throughput distribution channels.

Urban Fulfillment Centers

Urban fulfillment centers optimize wholesale distribution by reducing delivery times and transportation costs, leveraging proximity to dense consumer markets. Micro-fulfillment integrates automated storage and retrieval systems in these centers, enhancing inventory accuracy and order fulfillment speed for wholesale operations in urban areas.

Parcel Consolidation

Wholesale distribution leverages parcel consolidation to reduce shipping costs and improve delivery efficiency by combining multiple shipments into a single parcel, contrasting with micro-fulfillment centers that prioritize rapid local order fulfillment but often incur higher per-package expenses. Parcel consolidation in wholesale enhances supply chain scalability and lowers carbon footprint through optimized logistics, making it a cost-effective strategy compared to the fragmented shipping approach of micro-fulfillment.

Distributed Micro-Depots

Distributed micro-depots enhance wholesale operations by decentralizing inventory storage, enabling faster order fulfillment and reducing last-mile delivery costs. This localized approach supports scalable distribution networks, improves supply chain resilience, and meets increasing consumer demands for quicker delivery times.

Hyperlocal Resupply

Wholesale distribution leverages bulk purchasing and centralized inventory management to supply retailers efficiently, while micro-fulfillment centers enable rapid hyperlocal resupply through automation and proximity to end customers. Hyperlocal resupply optimizes last-mile delivery times, reducing transportation costs and enhancing stock availability in urban and densely populated areas.

Wholesale vs Micro-fulfillment Infographic

industrydif.com

industrydif.com