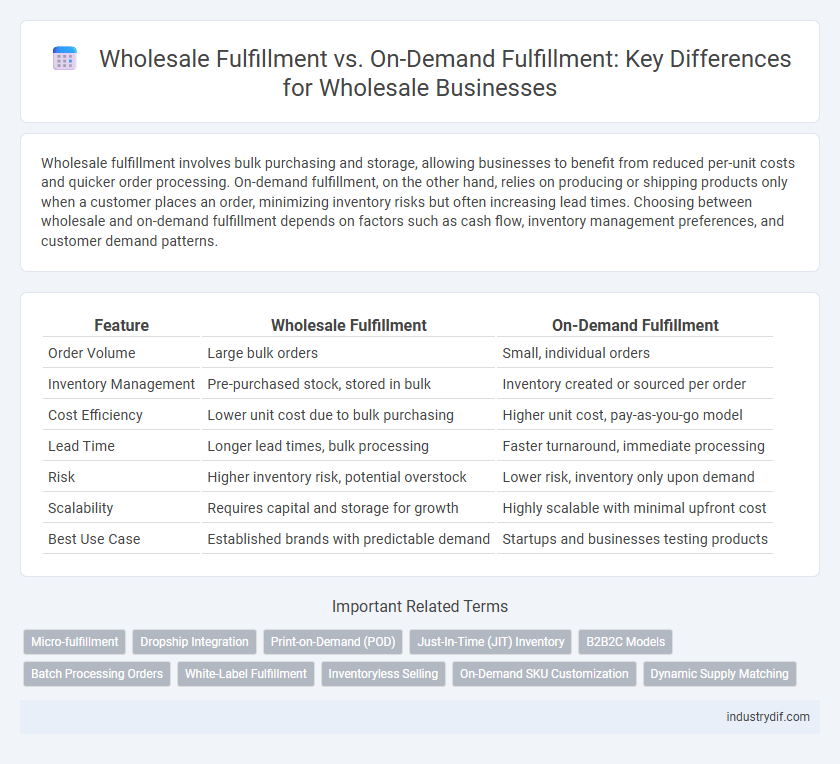

Wholesale fulfillment involves bulk purchasing and storage, allowing businesses to benefit from reduced per-unit costs and quicker order processing. On-demand fulfillment, on the other hand, relies on producing or shipping products only when a customer places an order, minimizing inventory risks but often increasing lead times. Choosing between wholesale and on-demand fulfillment depends on factors such as cash flow, inventory management preferences, and customer demand patterns.

Table of Comparison

| Feature | Wholesale Fulfillment | On-Demand Fulfillment |

|---|---|---|

| Order Volume | Large bulk orders | Small, individual orders |

| Inventory Management | Pre-purchased stock, stored in bulk | Inventory created or sourced per order |

| Cost Efficiency | Lower unit cost due to bulk purchasing | Higher unit cost, pay-as-you-go model |

| Lead Time | Longer lead times, bulk processing | Faster turnaround, immediate processing |

| Risk | Higher inventory risk, potential overstock | Lower risk, inventory only upon demand |

| Scalability | Requires capital and storage for growth | Highly scalable with minimal upfront cost |

| Best Use Case | Established brands with predictable demand | Startups and businesses testing products |

Definition of Wholesale Fulfillment

Wholesale fulfillment involves managing large-volume inventory shipments directly from manufacturers or suppliers to retailers or distributors, optimizing cost efficiency through bulk orders. This process typically includes warehousing, order processing, and logistics tailored for high-quantity transactions, reducing per-unit shipping costs and streamlining supply chain operations. Wholesale fulfillment contrasts with on-demand fulfillment by emphasizing bulk inventory handling rather than single or small-batch order processing.

Understanding On-Demand Fulfillment

On-demand fulfillment streamlines inventory management by producing or sourcing products only after a customer places an order, reducing storage costs and minimizing excess stock risk. This fulfillment method supports customization and rapid response to market trends, enhancing customer satisfaction and operational flexibility. Unlike traditional wholesale, on-demand fulfillment prioritizes agility and efficiency, aligning production closely with real-time demand data.

Key Differences Between Wholesale and On-Demand Fulfillment

Wholesale fulfillment involves purchasing and storing large quantities of products upfront, enabling bulk shipping to retailers or customers, which often results in lower per-unit costs. On-demand fulfillment operates by producing or sourcing items only after receiving customer orders, minimizing inventory risks but typically leading to higher costs and longer delivery times. The key differences lie in inventory management, cost structures, and speed of order fulfillment, with wholesale favoring economies of scale and on-demand emphasizing flexibility and reduced upfront investment.

Inventory Management in Wholesale vs On-Demand

Wholesale inventory management involves purchasing and storing large quantities of products upfront, which requires accurate demand forecasting and efficient warehouse organization to prevent overstocking and stockouts. On-demand fulfillment eliminates the need for large inventory holdings by sourcing products only when orders are placed, reducing storage costs and minimizing inventory risks. However, wholesale offers economies of scale and bulk pricing advantages that on-demand models typically cannot match.

Cost Structures: Wholesale vs On-Demand Fulfillment

Wholesale fulfillment typically involves bulk purchasing and storage costs, leading to lower per-unit expenses due to economies of scale and predictable inventory management. On-demand fulfillment eliminates large upfront inventory investments but incurs higher per-order fees and variable shipping costs, impacting overall profitability. Businesses must evaluate fixed inventory carrying costs against flexible, pay-as-you-go expenses to determine the optimal cost structure for their fulfillment model.

Scalability and Flexibility Compared

Wholesale fulfillment offers high scalability through bulk order processing, enabling businesses to manage large inventories efficiently and reduce per-unit costs. In contrast, on-demand fulfillment provides greater flexibility by allowing customization and smaller batch shipments aligned with real-time consumer demand. Companies seeking rapid growth benefit from wholesale scalability, while those prioritizing market responsiveness often prefer on-demand fulfillment models.

Order Volume and Processing Speed

Wholesale fulfillment handles large order volumes with bulk processing, resulting in slower individual order turnaround but economies of scale. On-demand fulfillment excels in rapid processing speed for smaller orders, offering swift delivery and flexibility. Businesses with high-volume, predictable demand benefit from wholesale, while those requiring agility favor on-demand fulfillment.

Suitability for Different Business Models

Wholesale fulfillment suits businesses with high volume sales and consistent demand, offering lower costs per unit through bulk purchasing and storage. On-demand fulfillment works best for startups and niche markets by minimizing inventory risk and allowing flexible, made-to-order production. Choosing between the two depends on cash flow, target customer base, and scalability needs within a business model.

Impact on Customer Experience

Wholesale offers consistent product availability and faster shipping times, enhancing customer satisfaction through reliable inventory and bulk order fulfillment. On-demand fulfillment provides personalized, customizable products with reduced inventory costs but may experience longer delivery times, impacting customer expectations. Balancing wholesale efficiency with on-demand flexibility can optimize overall customer experience by aligning speed, variety, and personalization.

Choosing the Right Fulfillment Model for Your Business

Wholesale fulfillment involves large inventory purchases stored and shipped in bulk, minimizing per-unit costs and enabling predictable supply chain management. On-demand fulfillment allows for smaller, customized orders shipped directly to customers, reducing inventory risks and improving cash flow flexibility. Selecting the right model depends on factors like product demand consistency, storage capacity, budget constraints, and the need for rapid market responsiveness.

Related Important Terms

Micro-fulfillment

Micro-fulfillment centers enhance wholesale distribution by enabling faster, localized inventory management compared to on-demand fulfillment, which prioritizes single-order processing. Leveraging automation and proximity to urban consumers, micro-fulfillment optimizes stock turnover rates and reduces last-mile delivery costs, streamlining the wholesale supply chain.

Dropship Integration

Wholesale enables bulk inventory management while dropship integration in on-demand fulfillment streamlines order processing by directly linking suppliers with retailers, reducing storage costs and delivery times. Dropship integration optimizes supply chain efficiency by synchronizing product availability, pricing updates, and real-time order tracking between wholesale distributors and retail platforms.

Print-on-Demand (POD)

Wholesale involves purchasing bulk inventory at lower costs to sell through various channels, whereas On-Demand Fulfillment in Print-on-Demand (POD) allows retailers to print and ship customized products only after a customer places an order, minimizing upfront investment and reducing inventory risk. POD streamlines operations by integrating with online platforms, offering scalability and flexibility that contrasts with the traditional wholesale model's reliance on bulk stock and storage.

Just-In-Time (JIT) Inventory

Just-In-Time (JIT) inventory in wholesale minimizes holding costs by synchronizing stock arrival closely with demand, reducing excess inventory and storage expenses. On-demand fulfillment bypasses traditional bulk purchasing, enabling faster response times and decreased lead times through direct supplier-to-customer shipping, optimizing cash flow and inventory turnover.

B2B2C Models

Wholesale fulfillment in B2B2C models enables bulk inventory management and predictable delivery timelines, reducing per-unit costs and improving margin stability for suppliers. On-demand fulfillment offers greater flexibility with just-in-time order processing, minimizing inventory risk and allowing retailers to quickly respond to consumer demand fluctuations.

Batch Processing Orders

Wholesale batch processing orders streamline inventory management by handling large volumes simultaneously, reducing handling time and operational costs. On-demand fulfillment processes orders individually, offering flexibility but often increasing lead times and higher per-unit expenses.

White-Label Fulfillment

White-label fulfillment offers wholesale businesses a scalable solution by allowing them to brand products and packaging without managing inventory or shipping, enhancing customer loyalty and operational efficiency. Unlike on-demand fulfillment, wholesale white-label services typically involve bulk order processing that reduces per-unit costs and streamlines supply chain management.

Inventoryless Selling

Wholesale fulfillment relies on bulk inventory purchases and storage, enabling faster shipping and lower per-unit costs, while on-demand fulfillment utilizes inventoryless selling by directly sourcing products from suppliers only after a customer places an order, reducing overhead and minimizing stock risks. Inventoryless selling in on-demand fulfillment optimizes cash flow and inventory management but may lead to longer delivery times compared to wholesale models holding stock in advance.

On-Demand SKU Customization

On-demand SKU customization enables businesses to tailor products individually, reducing inventory costs and minimizing waste compared to traditional wholesale models that require bulk purchasing. This flexibility enhances customer satisfaction by offering personalized options while streamlining supply chain efficiency.

Dynamic Supply Matching

Wholesale leverages bulk inventory purchasing to secure lower unit costs, enabling consistent product availability and better price stability, while on-demand fulfillment dynamically matches supply with real-time consumer demand to minimize excess stock and reduce holding costs. Dynamic supply matching in on-demand models optimizes inventory by aligning production and distribution with immediate market needs, contrasting with wholesale's pre-purchased stock that relies on forecast accuracy.

Wholesale vs On-Demand Fulfillment Infographic

industrydif.com

industrydif.com