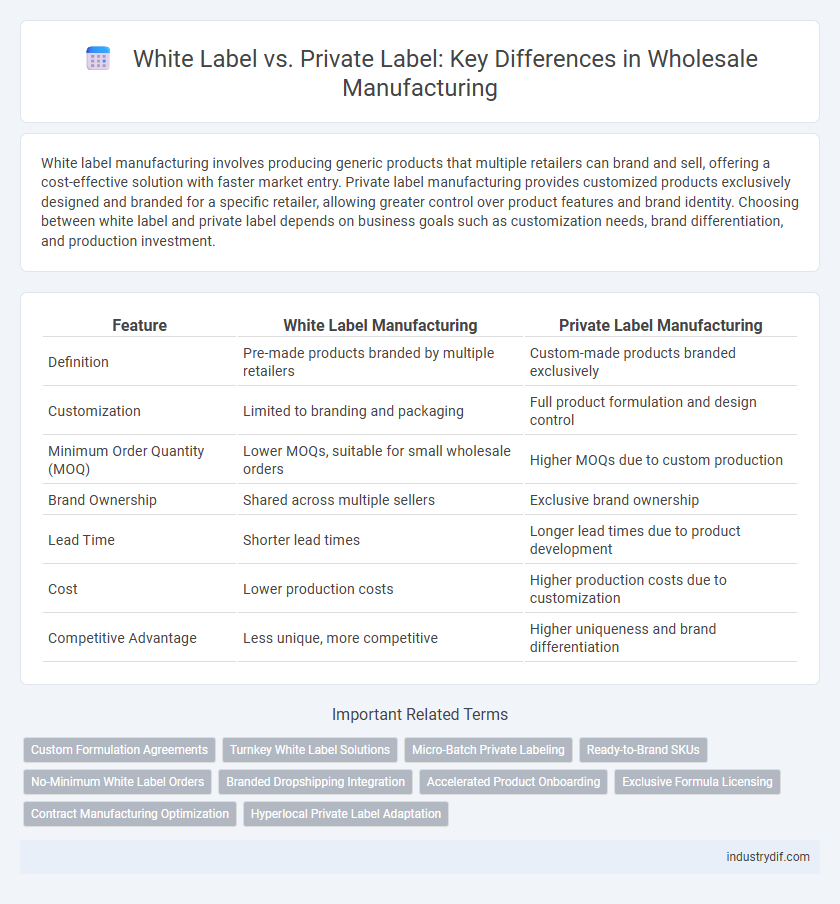

White label manufacturing involves producing generic products that multiple retailers can brand and sell, offering a cost-effective solution with faster market entry. Private label manufacturing provides customized products exclusively designed and branded for a specific retailer, allowing greater control over product features and brand identity. Choosing between white label and private label depends on business goals such as customization needs, brand differentiation, and production investment.

Table of Comparison

| Feature | White Label Manufacturing | Private Label Manufacturing |

|---|---|---|

| Definition | Pre-made products branded by multiple retailers | Custom-made products branded exclusively |

| Customization | Limited to branding and packaging | Full product formulation and design control |

| Minimum Order Quantity (MOQ) | Lower MOQs, suitable for small wholesale orders | Higher MOQs due to custom production |

| Brand Ownership | Shared across multiple sellers | Exclusive brand ownership |

| Lead Time | Shorter lead times | Longer lead times due to product development |

| Cost | Lower production costs | Higher production costs due to customization |

| Competitive Advantage | Less unique, more competitive | Higher uniqueness and brand differentiation |

Introduction to White Label and Private Label Manufacturing

White label manufacturing involves producing generic products that retailers can rebrand and sell under their own name without customization, allowing for quick market entry and reduced development costs. Private label manufacturing offers customization of products or packaging, enabling retailers to create unique brand identities and cater to specific target markets with greater control over product features. Both models streamline wholesale operations but differ primarily in branding flexibility and product differentiation.

Defining White Label Manufacturing

White label manufacturing involves producing generic products that retailers or companies can brand and sell as their own, allowing businesses to offer a wide range of products without investing in product development or manufacturing facilities. This model enables faster market entry and reduced overhead costs, as manufacturers handle production, quality control, and compliance. Companies benefit from turnkey solutions with white label products that can be customized only in packaging and branding, often used in industries like cosmetics, electronics, and food.

Defining Private Label Manufacturing

Private label manufacturing involves producing goods that retailers brand and sell as their own, typically allowing full control over product specifications and packaging. This approach enables businesses to create unique products without investing in production facilities, benefiting from manufacturers' expertise and economies of scale. Private label products often foster brand loyalty and higher profit margins compared to generic wholesale items.

Key Differences Between White Label and Private Label

White label manufacturing involves producing generic products that multiple retailers can rebrand and sell, whereas private label manufacturing creates products exclusively designed and branded for a specific retailer. White label products typically offer limited customization options, while private label products provide extensive control over ingredients, packaging, and branding to align with a retailer's unique market strategy. The choice between white label and private label manufacturing significantly impacts product differentiation, pricing strategy, and customer loyalty in wholesale business models.

Pros and Cons of White Label Manufacturing

White label manufacturing offers the advantage of quick market entry and lower upfront costs by utilizing pre-existing products that can be rebranded, reducing development time and expenses. However, it limits product differentiation and control over quality and features, which can impact brand uniqueness and customer loyalty. Businesses relying on white label solutions may face challenges in scalability and customization compared to private label manufacturing options.

Pros and Cons of Private Label Manufacturing

Private label manufacturing allows businesses to offer custom-branded products without the high costs of starting from scratch, providing greater control over product quality and brand identity. However, this approach requires significant initial investment, including minimum order quantities and longer lead times, which can pose risks for smaller retailers. Limited flexibility in product design and reliance on the manufacturer's production capabilities may also restrict innovation and responsiveness to market changes.

Choosing the Right Labeling Strategy for Your Business

White label manufacturing allows businesses to rebrand existing products from manufacturers, enabling faster market entry with lower development costs. Private label manufacturing offers greater customization and control over product design, branding, and formulation, which can enhance brand differentiation and customer loyalty. Selecting the right labeling strategy depends on factors such as budget, product uniqueness, time-to-market, and long-term branding goals to optimize wholesale success.

Impact on Branding and Market Positioning

White label manufacturing enables retailers to quickly offer a wide range of products under their own brand, enhancing brand visibility with minimal development costs, but often faces challenges in differentiation and market positioning. Private label manufacturing allows brands to create unique products tailored to their specific market needs, strengthening brand identity and customer loyalty by offering exclusivity and control over quality standards. Both strategies influence market positioning, with white label emphasizing speed and variety, while private label focuses on distinctiveness and long-term brand equity.

Cost Implications and Profit Margins

White label manufacturing typically involves lower upfront costs as products are pre-made and branded by the retailer, allowing for quicker market entry with reduced investment. Private label manufacturing requires higher initial expenses due to customization, product development, and smaller minimum order quantities, but it enables greater control over product differentiation and pricing. Profit margins tend to be higher with private label products because retailers can set premium prices and build brand loyalty, whereas white label products often compete primarily on price.

Industry Examples: White Label vs Private Label in Wholesale

In wholesale, white label products like electronics often involve retailers selling generic, pre-made items under their own brand without customization, exemplified by companies such as Best Buy offering generic smartphone accessories. Private label manufacturing, prevalent in the food and beverage sector with brands like Trader Joe's, features wholesale producers creating exclusive products tailored to the retailer's specifications and branding. This distinction impacts inventory control, profit margins, and brand differentiation strategies within the wholesale market.

Related Important Terms

Custom Formulation Agreements

Custom formulation agreements in white label manufacturing allow businesses to sell pre-existing products under their brand with minor modifications, minimizing development costs and time to market. Private label manufacturing involves creating unique product formulations tailored specifically to a brand's specifications, providing greater control over ingredients, quality, and differentiation in wholesale markets.

Turnkey White Label Solutions

Turnkey white label solutions offer businesses a complete, ready-to-sell product package that includes manufacturing, branding, packaging, and distribution, significantly reducing time-to-market and operational complexity. Unlike private label manufacturing, which often requires customization and higher involvement in product development, turnkey white label services provide scalable inventory management with established supply chain reliability across wholesale markets.

Micro-Batch Private Labeling

Micro-batch private labeling allows manufacturers to produce smaller, highly customized product runs ideal for niche markets, offering greater flexibility than traditional white label manufacturing which relies on pre-designed products. This approach enables brands to maintain unique formulations and packaging while benefiting from reduced inventory risks and faster market responsiveness.

Ready-to-Brand SKUs

White label manufacturing offers ready-to-brand SKUs developed and produced by third parties, allowing retailers to quickly launch products without customization, while private label manufacturing involves creating exclusive products tailored to specific brand requirements and unique formulations. Choosing white label SKUs streamlines inventory management and reduces time-to-market, whereas private label manufacturing supports brand differentiation and long-term customer loyalty through proprietary offerings.

No-Minimum White Label Orders

No-minimum white label orders allow businesses to source branded products without large inventory commitments, offering flexibility and reduced financial risk compared to private label manufacturing, which often requires higher minimum order quantities for custom branding and formulation. This approach is ideal for startups and small retailers aiming to test markets quickly with scalable, ready-made products while maintaining brand consistency.

Branded Dropshipping Integration

White label manufacturing enables businesses to rebrand generic products without customization, streamlining branded dropshipping integration for faster market entry and consistent quality control. Private label manufacturing offers tailored product design and unique branding, enhancing brand differentiation and enabling premium pricing in wholesale dropshipping platforms.

Accelerated Product Onboarding

White label manufacturing enables accelerated product onboarding by providing pre-designed products that wholesalers can brand quickly, reducing development time and upfront costs. Private label manufacturing offers more customization options but requires longer lead times due to unique product development and testing processes.

Exclusive Formula Licensing

Exclusive formula licensing distinguishes white label manufacturing by allowing retailers to market products created from proprietary formulations not available to competitors, enhancing brand uniqueness. Private label manufacturing typically offers products manufactured under a retailer's brand but without exclusive rights to the formula, limiting differentiation in the wholesale market.

Contract Manufacturing Optimization

White label manufacturing offers pre-designed products that wholesalers can rebrand, enabling faster market entry with lower development costs, while private label manufacturing involves custom product development tailored to specific brand requirements, allowing greater differentiation and control. Contract manufacturing optimization focuses on streamlining production processes, reducing lead times, and ensuring quality compliance to maximize efficiency and profitability in both white label and private label models.

Hyperlocal Private Label Adaptation

Hyperlocal private label manufacturing enables brands to tailor products to regional preferences and consumer behaviors, leveraging local resources and reducing supply chain complexity. Unlike standard white label production, hyperlocal adaptation fosters stronger brand differentiation and customer loyalty by reflecting community-specific tastes and cultural nuances.

White Label vs Private Label Manufacturing Infographic

industrydif.com

industrydif.com