Wholesale sourcing involves purchasing large quantities of products at discounted rates to maintain inventory, offering cost efficiency and consistent supply for businesses. On-demand sourcing allows companies to order products as needed, reducing inventory costs and minimizing waste but often at higher per-unit prices. Choosing between wholesale and on-demand sourcing depends on factors like demand predictability, storage capacity, and cash flow management.

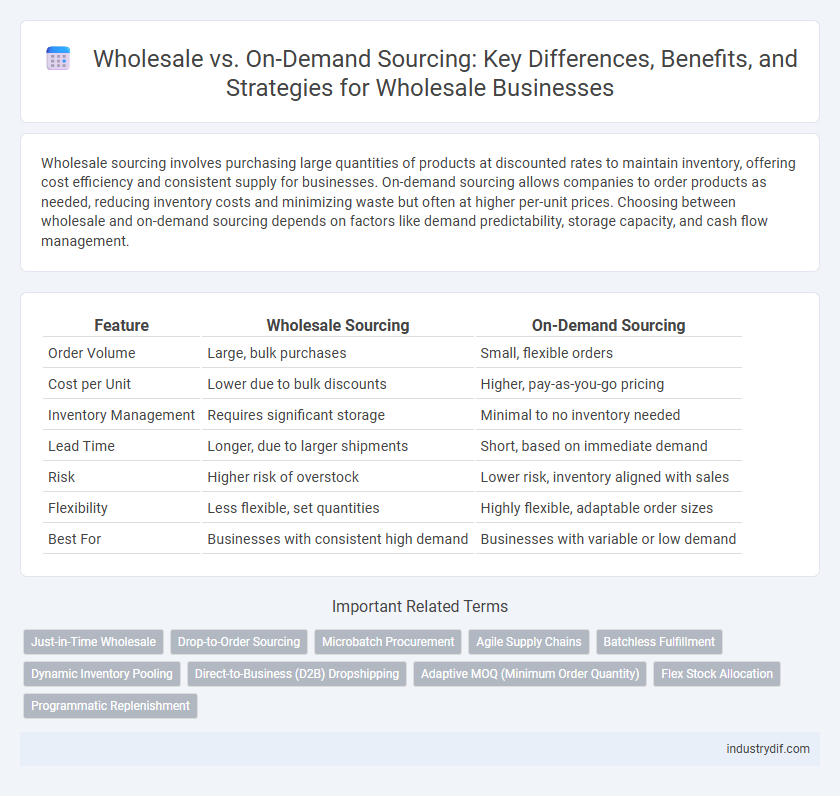

Table of Comparison

| Feature | Wholesale Sourcing | On-Demand Sourcing |

|---|---|---|

| Order Volume | Large, bulk purchases | Small, flexible orders |

| Cost per Unit | Lower due to bulk discounts | Higher, pay-as-you-go pricing |

| Inventory Management | Requires significant storage | Minimal to no inventory needed |

| Lead Time | Longer, due to larger shipments | Short, based on immediate demand |

| Risk | Higher risk of overstock | Lower risk, inventory aligned with sales |

| Flexibility | Less flexible, set quantities | Highly flexible, adaptable order sizes |

| Best For | Businesses with consistent high demand | Businesses with variable or low demand |

Introduction to Wholesale and On-Demand Sourcing

Wholesale involves purchasing large quantities of products at discounted rates, enabling businesses to maintain inventory for consistent customer demand. On-demand sourcing, by contrast, focuses on procuring goods as orders come in, reducing inventory costs and minimizing storage risks. Both strategies impact supply chain efficiency and capital allocation differently, influencing overall business scalability and responsiveness.

Defining Wholesale in the Modern Marketplace

Wholesale in the modern marketplace involves purchasing goods in large quantities directly from manufacturers or distributors at discounted rates to supply retailers or other businesses. This model emphasizes bulk transactions, streamlined inventory management, and cost-efficiency compared to on-demand sourcing, which focuses on smaller, just-in-time orders tailored to immediate demand. Wholesale's advantage lies in securing lower unit prices and fostering long-term supplier relationships, driving competitive pricing and consistent product availability for downstream sellers.

What is On-Demand Sourcing?

On-demand sourcing is a procurement strategy where products or materials are purchased only as they are needed, minimizing inventory costs and reducing waste. This approach leverages real-time data and flexible supplier relationships to quickly respond to market demands and fluctuating customer orders. It contrasts with wholesale sourcing, which involves buying large quantities upfront, often leading to bulk discounts but increased storage and capital expenses.

Key Differences Between Wholesale and On-Demand Sourcing

Wholesale sourcing involves purchasing large quantities of products upfront from suppliers at reduced prices, enabling businesses to maintain inventory and meet consistent demand. On-demand sourcing relies on acquiring products only when orders are received, minimizing inventory costs but potentially increasing lead times. Key differences include inventory management, capital investment, and supply chain flexibility, where wholesale requires higher upfront investment, whereas on-demand sourcing offers greater adaptability to market fluctuations.

Pros and Cons of Wholesale Sourcing

Wholesale sourcing offers the advantage of bulk purchasing, leading to lower per-unit costs and consistent inventory availability, which supports scalable business operations. However, it requires significant upfront investment and storage capacity, increasing financial risk and potential for unsold stock. Limited product flexibility and slower adaptation to market trends can also hinder responsiveness compared to on-demand sourcing models.

Advantages and Disadvantages of On-Demand Sourcing

On-demand sourcing offers flexibility by allowing businesses to order products as needed, minimizing inventory costs and reducing the risk of overstock or obsolescence. However, it may lead to longer lead times and potential supply chain disruptions compared to wholesale sourcing, which benefits from bulk purchasing and lower per-unit costs. This method suits companies prioritizing agility over immediate large inventory availability, but can challenge consistent supply reliability and pricing stability.

Impact on Inventory Management

Wholesale sourcing enables bulk purchasing that streamlines inventory management by maintaining consistent stock levels and reducing the risk of stockouts. On-demand sourcing minimizes inventory holding costs by acquiring products only when orders are confirmed, which limits excess stock and storage needs. Efficient inventory management depends on selecting the appropriate sourcing strategy aligned with demand variability and cash flow considerations.

Cost Structure Comparison

Wholesale sourcing offers lower per-unit costs due to bulk purchasing and fixed inventory expenses, enabling businesses to optimize margins through volume discounts and reduced shipping fees. On-demand sourcing involves higher variable costs per item, including premium pricing and expedited shipping, but minimizes inventory holding costs and reduces risk of overstock. Balancing fixed wholesale costs against flexible on-demand expenses is critical for maintaining profitability and cash flow in supply chain management.

Choosing the Right Sourcing Model for Your Business

Wholesale sourcing offers bulk purchasing at lower costs, ideal for businesses seeking consistent inventory and predictable cash flow. On-demand sourcing allows for flexible, just-in-time ordering, reducing inventory risk and aligning with fluctuating customer demand. Assessing your business's sales volume, storage capacity, and cash flow will determine the optimal sourcing model to maximize efficiency and profitability.

Future Trends in Wholesale and On-Demand Sourcing

Future trends in wholesale emphasize digital transformation, with AI-driven inventory management and predictive analytics optimizing supply chains. On-demand sourcing leverages real-time data and decentralized networks to enhance flexibility and reduce lead times. Integration of blockchain technology across both models ensures transparency and traceability, shaping a more resilient and efficient procurement landscape.

Related Important Terms

Just-in-Time Wholesale

Just-in-Time Wholesale minimizes inventory costs by synchronizing supply deliveries precisely with production schedules, contrasting sharply with On-Demand Sourcing that often relies on rapid fulfillment from dispersed suppliers. This approach enhances cash flow and reduces storage needs in wholesale operations by leveraging predictive analytics and supplier integration for timely stock replenishment.

Drop-to-Order Sourcing

Drop-to-Order sourcing merges the efficiency of wholesale purchasing with the agility of on-demand supply, enabling businesses to reduce inventory risks while maintaining consistent product availability. Unlike traditional wholesale, this model triggers supplier orders only after customer demand is confirmed, optimizing cash flow and minimizing storage costs.

Microbatch Procurement

Microbatch procurement in wholesale enables bulk purchasing of smaller, precise quantities, reducing inventory costs and minimizing waste compared to traditional on-demand sourcing. This approach enhances supply chain efficiency by balancing demand forecasting accuracy with flexible order fulfillment, optimizing overall operational scalability.

Agile Supply Chains

Wholesale sourcing leverages bulk purchasing and inventory stockpiling to ensure consistent product availability, supporting agile supply chains through predictable demand fulfillment and reduced lead times. On-demand sourcing enhances supply chain responsiveness by minimizing inventory holding costs and enabling rapid adaptation to market fluctuations, crucial for maintaining agility in dynamic wholesale environments.

Batchless Fulfillment

Batchless fulfillment revolutionizes wholesale by eliminating large inventory batches, enabling suppliers to fulfill orders on-demand with precise quantities. This approach reduces storage costs, minimizes waste, and enhances supply chain agility compared to traditional wholesale sourcing that relies on bulk purchasing and stockpiling.

Dynamic Inventory Pooling

Dynamic inventory pooling in wholesale consolidates stock from multiple suppliers to optimize product availability and reduce lead times, enhancing supply chain efficiency. On-demand sourcing relies on real-time procurement, which increases flexibility but may result in higher costs and inconsistent inventory levels compared to wholesale's bulk inventory management.

Direct-to-Business (D2B) Dropshipping

Wholesale sourcing enables businesses to purchase large quantities of products upfront, securing lower costs per unit and maintaining consistent inventory for direct-to-business (D2B) dropshipping. On-demand sourcing minimizes inventory holding by ordering products only after a sale, allowing D2B dropshippers to reduce overhead and respond quickly to market demand fluctuations.

Adaptive MOQ (Minimum Order Quantity)

Adaptive MOQ in wholesale sourcing enables flexible order quantities tailored to buyers' demand patterns, reducing inventory risk and enhancing supply chain responsiveness compared to rigid on-demand sourcing models. This approach optimizes production efficiency and cost-effectiveness by aligning minimum order thresholds with real-time market fluctuations and bulk purchasing advantages.

Flex Stock Allocation

Flex Stock Allocation in wholesale enables dynamic inventory distribution across multiple sales channels, optimizing stock levels and reducing holding costs. Compared to on-demand sourcing, it ensures faster order fulfillment by maintaining a flexible supply buffer tailored to fluctuating demand patterns.

Programmatic Replenishment

Wholesale offers bulk purchasing advantages and cost efficiencies through programmatic replenishment, enabling automated inventory management based on predictive analytics and sales velocity. On-demand sourcing, while flexible, lacks the seamless, data-driven replenishment cycles that wholesale programs optimize for consistent stock levels and reduced lead times.

Wholesale vs On-Demand Sourcing Infographic

industrydif.com

industrydif.com