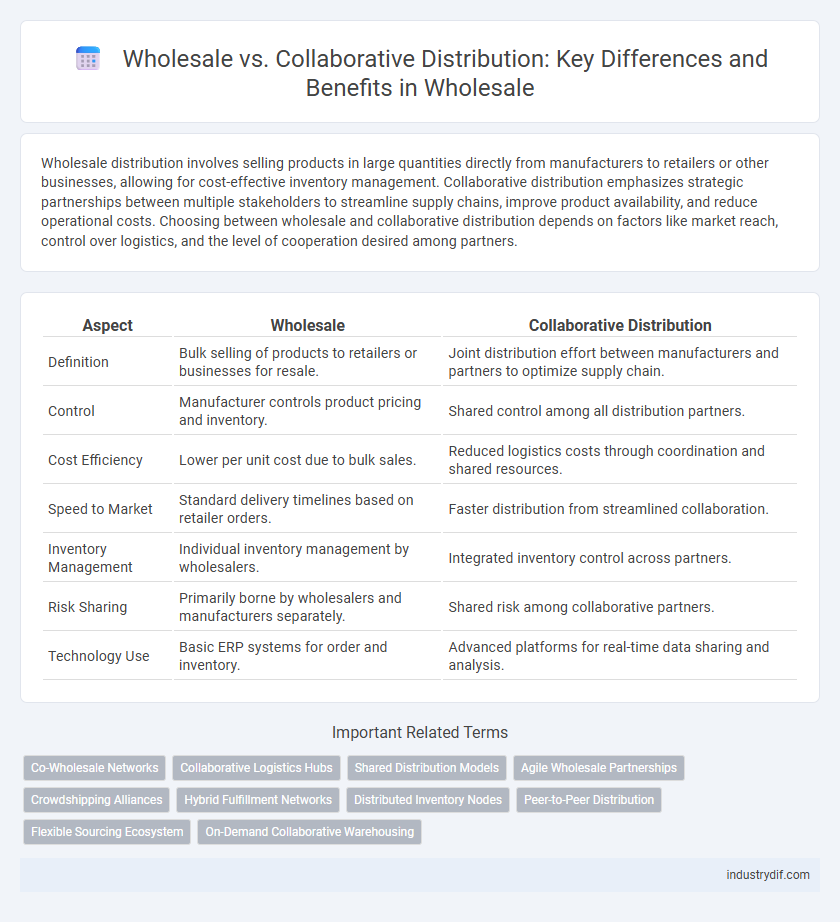

Wholesale distribution involves selling products in large quantities directly from manufacturers to retailers or other businesses, allowing for cost-effective inventory management. Collaborative distribution emphasizes strategic partnerships between multiple stakeholders to streamline supply chains, improve product availability, and reduce operational costs. Choosing between wholesale and collaborative distribution depends on factors like market reach, control over logistics, and the level of cooperation desired among partners.

Table of Comparison

| Aspect | Wholesale | Collaborative Distribution |

|---|---|---|

| Definition | Bulk selling of products to retailers or businesses for resale. | Joint distribution effort between manufacturers and partners to optimize supply chain. |

| Control | Manufacturer controls product pricing and inventory. | Shared control among all distribution partners. |

| Cost Efficiency | Lower per unit cost due to bulk sales. | Reduced logistics costs through coordination and shared resources. |

| Speed to Market | Standard delivery timelines based on retailer orders. | Faster distribution from streamlined collaboration. |

| Inventory Management | Individual inventory management by wholesalers. | Integrated inventory control across partners. |

| Risk Sharing | Primarily borne by wholesalers and manufacturers separately. | Shared risk among collaborative partners. |

| Technology Use | Basic ERP systems for order and inventory. | Advanced platforms for real-time data sharing and analysis. |

Understanding Wholesale: Definition and Key Features

Wholesale involves purchasing goods in bulk directly from manufacturers to sell them at lower prices to retailers or other businesses, enabling economies of scale and cost efficiency. Key features include large volume transactions, lower per-unit costs, and a streamlined supply chain that reduces intermediaries. Unlike collaborative distribution, wholesale centers on ownership transfer without ongoing partnerships in logistics or inventory management.

What is Collaborative Distribution?

Collaborative distribution is a supply chain strategy where multiple businesses share resources, inventory, and logistics to improve efficiency and reduce costs. Unlike traditional wholesale, which involves a one-way transaction from supplier to retailer, collaborative distribution emphasizes partnership and coordination among participants to meet demand more effectively. This approach leverages technology and real-time data sharing to optimize inventory levels, minimize delivery times, and enhance customer satisfaction in wholesale networks.

Core Differences Between Wholesale and Collaborative Distribution

Wholesale involves selling goods in large quantities directly from manufacturers to retailers or other businesses, emphasizing volume-based transactions and standardized pricing. Collaborative distribution includes cooperative partnerships where multiple companies share resources, logistics, and networks to optimize supply chain efficiency and reduce costs. Core differences lie in control over inventory, decision-making processes, and the degree of shared responsibility for distribution outcomes.

Advantages of Wholesale Distribution

Wholesale distribution offers significant advantages including bulk purchasing that reduces per-unit costs and streamlines inventory management for retailers. It enables faster delivery times through established logistics networks, enhancing supply chain efficiency and ensuring product availability. Wholesale distribution also provides greater control over pricing and marketing strategies, supporting consistent brand positioning in the market.

Benefits of Collaborative Distribution Models

Collaborative distribution models increase supply chain efficiency by fostering shared resources and real-time data exchange among partners, reducing inventory costs and improving delivery speed. These models enhance market reach and customer satisfaction through synchronized demand forecasting and tailored product offerings. Businesses benefit from stronger partnerships and risk mitigation by leveraging collective expertise and integrated logistics networks.

Cost Structures: Wholesale vs Collaborative Distribution

Wholesale cost structures typically involve higher fixed expenses due to inventory holding, warehousing, and bulk purchasing commitments, resulting in significant upfront investment and risk. Collaborative distribution, however, reduces these costs by sharing resources, such as logistics and inventory management, among partners, leading to lower variable costs and increased operational flexibility. By distributing expenses across multiple stakeholders, collaborative distribution often achieves enhanced cost efficiency and scalability compared to traditional wholesale models.

Supply Chain Efficiency in Wholesale vs Collaborative Distribution

Wholesale distribution streamlines supply chain efficiency by maintaining centralized inventory and bulk purchasing, reducing costs through economies of scale. Collaborative distribution enhances efficiency by sharing resources and data among partners, improving demand forecasting and reducing lead times. Both methods optimize supply chain performance, with wholesale emphasizing volume-driven cost savings and collaborative distribution focusing on integrated network agility.

Technology’s Role in Modern Distribution Approaches

Technology drives efficiency in wholesale by automating inventory management, streamlining order processing, and enhancing supply chain visibility, leading to reduced costs and faster delivery times. Collaborative distribution leverages advanced digital platforms and data analytics to synchronize activities among multiple stakeholders, fostering real-time communication and shared resources. Integrating IoT, AI, and cloud computing optimizes both models, enabling predictive insights and adaptive strategies that meet evolving market demands.

Choosing the Right Model: Factors to Consider

Selecting the appropriate distribution model depends on factors such as product type, market reach, and control over branding. Wholesale offers scalability and faster market penetration through bulk sales to retailers, while collaborative distribution emphasizes partnership, shared resources, and enhanced customer relationships. Evaluating cost structures, supply chain complexity, and long-term business goals helps determine whether wholesale or collaborative distribution best aligns with company objectives.

Future Trends: Wholesale and Collaborative Distribution

Future trends in wholesale and collaborative distribution emphasize digital transformation and data-driven decision-making to enhance supply chain efficiency. Integration of AI and IoT technologies enables real-time inventory management and predictive analytics, fostering seamless coordination between wholesalers and collaborators. Sustainability and transparency are also becoming critical, driving the adoption of eco-friendly practices and blockchain solutions in distribution networks.

Related Important Terms

Co-Wholesale Networks

Co-Wholesale Networks enhance Wholesale by enabling multiple distributors to pool resources, streamline inventory management, and expand market reach collectively. This collaborative approach reduces operational costs and increases bargaining power compared to traditional Wholesale models.

Collaborative Logistics Hubs

Collaborative logistics hubs streamline wholesale distribution by integrating resources from multiple suppliers and retailers, reducing transportation costs and increasing delivery efficiency. These hubs enable real-time inventory sharing and coordinated order fulfillment, optimizing supply chain responsiveness compared to traditional wholesale methods.

Shared Distribution Models

Shared distribution models in wholesale leverage collaborative strategies where multiple businesses pool resources, inventory, and logistics to optimize supply chain efficiency and reduce costs. This approach enhances market reach and service flexibility compared to traditional wholesale by fostering transparency and real-time data sharing among partners.

Agile Wholesale Partnerships

Agile wholesale partnerships leverage real-time data integration and flexible supply chain strategies to optimize inventory management and reduce lead times compared to traditional wholesale and collaborative distribution models. These partnerships enhance responsiveness to market fluctuations, enabling faster product replenishment and improved customer satisfaction in wholesale operations.

Crowdshipping Alliances

Wholesale typically involves bulk purchasing and direct distribution from manufacturers to retailers, while collaborative distribution leverages crowdshipping alliances to optimize last-mile delivery through a network of independent couriers. Crowdshipping alliances enhance supply chain efficiency by reducing transportation costs, improving delivery speed, and increasing flexibility in meeting fluctuating demand.

Hybrid Fulfillment Networks

Hybrid fulfillment networks combine the strengths of wholesale distribution and collaborative distribution by integrating centralized inventory management with localized delivery, maximizing efficiency and reducing lead times. These networks leverage technology to optimize stock allocation across multiple partners, enhancing scalability and responsiveness in supply chains.

Distributed Inventory Nodes

Distributed inventory nodes in wholesale systems enhance supply chain efficiency by decentralizing stock across multiple locations, enabling faster fulfillment and reduced transportation costs. Collaborative distribution, while sharing inventory data among partners, often relies on centralized warehouses, which can limit the agility provided by a distributed node strategy.

Peer-to-Peer Distribution

Wholesale distribution predominantly relies on centralized supply chains and bulk transactions between manufacturers and retailers, while peer-to-peer distribution emphasizes direct exchanges within decentralized networks, enhancing flexibility and reducing intermediaries. This collaborative model leverages technology platforms to enable real-time inventory sharing and localized demand fulfillment, optimizing supply chain efficiency and responsiveness.

Flexible Sourcing Ecosystem

Wholesale leverages a flexible sourcing ecosystem by aggregating diverse suppliers to streamline inventory management and reduce costs, enabling businesses to respond swiftly to market demands. Collaborative distribution enhances this model by integrating real-time data sharing and joint logistics, optimizing supply chain transparency and operational efficiency.

On-Demand Collaborative Warehousing

On-demand collaborative warehousing in wholesale enables multiple businesses to share storage space and distribution resources, reducing costs and increasing supply chain flexibility. This model contrasts with traditional wholesale distribution by leveraging real-time data and technology to optimize inventory management and accelerate order fulfillment.

Wholesale vs Collaborative Distribution Infographic

industrydif.com

industrydif.com