Wholesale involves purchasing large quantities of products at discounted rates to maximize profit margins through volume sales. Smart inventory leverages data analytics and automation to optimize stock levels, reduce holding costs, and prevent both overstocking and stockouts. Integrating wholesale with smart inventory strategies enhances supply chain efficiency and drives better financial performance.

Table of Comparison

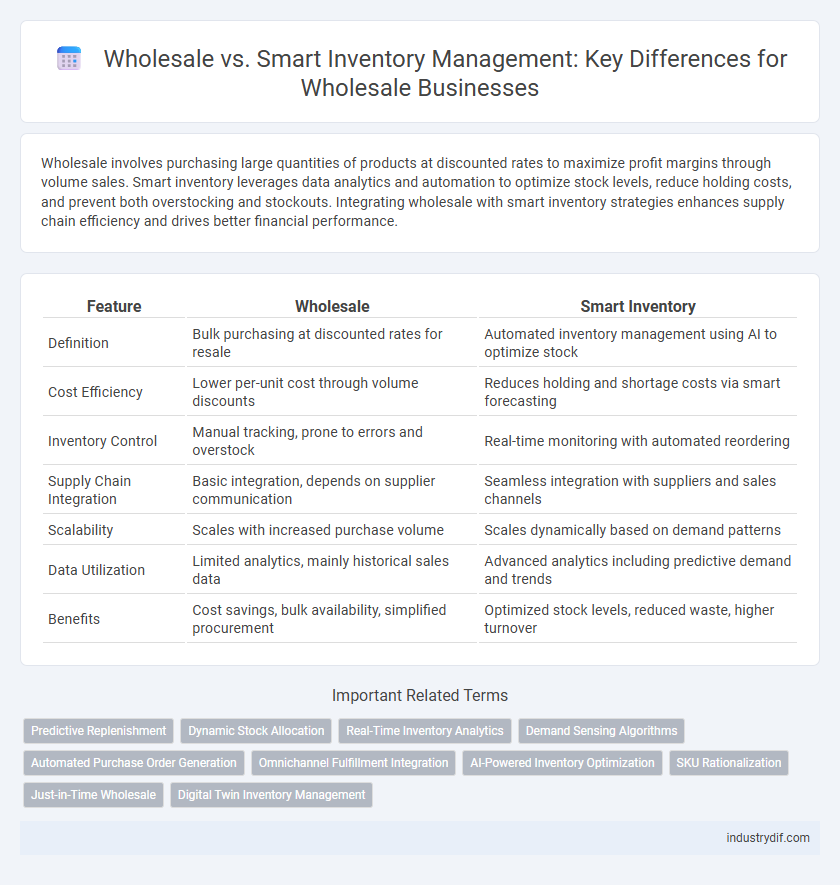

| Feature | Wholesale | Smart Inventory |

|---|---|---|

| Definition | Bulk purchasing at discounted rates for resale | Automated inventory management using AI to optimize stock |

| Cost Efficiency | Lower per-unit cost through volume discounts | Reduces holding and shortage costs via smart forecasting |

| Inventory Control | Manual tracking, prone to errors and overstock | Real-time monitoring with automated reordering |

| Supply Chain Integration | Basic integration, depends on supplier communication | Seamless integration with suppliers and sales channels |

| Scalability | Scales with increased purchase volume | Scales dynamically based on demand patterns |

| Data Utilization | Limited analytics, mainly historical sales data | Advanced analytics including predictive demand and trends |

| Benefits | Cost savings, bulk availability, simplified procurement | Optimized stock levels, reduced waste, higher turnover |

Understanding Wholesale: Key Concepts and Practices

Wholesale involves purchasing goods in large quantities directly from manufacturers or distributors to resell at a profit, emphasizing bulk buying, competitive pricing, and supply chain management. Smart inventory integrates technology and data analytics to optimize stock levels, reduce carrying costs, and improve order fulfillment efficiency in wholesale operations. Understanding these core concepts enables businesses to balance cost-efficiency with demand responsiveness, enhancing overall profitability.

What is Smart Inventory? Definition and Benefits

Smart inventory leverages advanced technologies like AI and IoT to optimize stock management by accurately forecasting demand and automating replenishment processes. This approach minimizes overstock and stockouts, reducing carrying costs and enhancing cash flow efficiency in wholesale operations. Implementing smart inventory systems boosts supply chain responsiveness and improves customer satisfaction through timely product availability.

Comparing Wholesale and Smart Inventory Models

Wholesale models emphasize bulk purchasing and traditional stock management, driving cost efficiency through volume discounts and fixed inventory levels. Smart inventory leverages real-time data analytics and demand forecasting to optimize stock, reduce holding costs, and enhance turnover rates. Comparing these models, wholesale focuses on scale and upfront investment, while smart inventory prioritizes agility and precision in supply chain management.

Efficiency Gains: Wholesale vs Smart Inventory

Wholesale systems often face challenges with overstock and stockouts, leading to inefficient capital use and lost sales opportunities. Smart Inventory leverages real-time data analytics and AI-driven demand forecasting to optimize stock levels, significantly reducing waste and improving turnover rates. These efficiency gains translate to lower carrying costs and enhanced responsiveness to market fluctuations, boosting overall profitability.

Cost Management in Wholesale and Smart Inventory

Wholesale cost management centers on bulk purchasing to leverage economies of scale and reduce per-unit expenses, optimizing inventory turnover to minimize holding costs. Smart inventory systems use real-time data analytics and demand forecasting to adjust stock levels dynamically, preventing overstock and stockouts, thereby cutting unnecessary storage expenses. Integrating smart inventory in wholesale operations enhances cost-efficiency by aligning procurement with actual market demand, streamlining cash flow and reducing waste.

Technology’s Role in Wholesale and Smart Inventory

Technology revolutionizes wholesale by enabling real-time data analytics, automated inventory tracking, and seamless supply chain integration, which significantly reduce stockouts and overstock scenarios. Smart inventory systems leverage AI-driven demand forecasting and IoT sensors to optimize stock levels, enhance order accuracy, and improve warehouse efficiency. These innovations empower wholesalers to minimize costs, increase turnover rates, and respond swiftly to market fluctuations.

Inventory Control: Traditional Wholesale vs Smart Systems

Traditional wholesale inventory control relies heavily on manual tracking, leading to increased risks of stockouts and overstocking. Smart inventory systems utilize real-time data analytics and automated replenishment, optimizing stock levels and reducing carrying costs. Integration of IoT sensors and AI-driven demand forecasting enhances accuracy and responsiveness in supply chain management.

Real-Time Data Impact: Smart Inventory Over Wholesale

Real-time data integration in smart inventory systems significantly enhances wholesale operations by providing instant updates on stock levels, demand fluctuations, and supply chain dynamics. This immediate visibility enables more accurate forecasting, reduces overstock and stockouts, and improves order fulfillment speed compared to traditional wholesale inventory methods. The resulting efficiency gains drive cost savings and responsive inventory management that meets market demands promptly.

Challenges in Transitioning from Wholesale to Smart Inventory

Transitioning from wholesale to smart inventory management poses challenges such as integrating advanced data analytics to accurately forecast demand and optimize stock levels. Companies must overcome legacy systems that lack real-time tracking and predictive capabilities, leading to potential supply chain disruptions. Adapting to smart inventory requires significant investment in technology and employee training to ensure seamless adoption and operational efficiency.

Future Trends: The Evolution from Wholesale to Smart Inventory

Future trends in wholesale emphasize the shift toward smart inventory systems that utilize AI, machine learning, and real-time data analytics to optimize stock levels and reduce waste. This evolution transforms traditional bulk purchasing models into adaptive supply chains that respond dynamically to market demand and consumer behavior. Integration of IoT devices and cloud-based platforms further enhances inventory accuracy and operational efficiency in wholesale distribution.

Related Important Terms

Predictive Replenishment

Predictive replenishment in wholesale leverages advanced data analytics and machine learning algorithms to forecast demand accurately, reducing stockouts and excess inventory. Smart inventory systems optimize order timing and quantities by analyzing historical sales patterns, supplier lead times, and market trends, ensuring efficient stock management across wholesale supply chains.

Dynamic Stock Allocation

Dynamic stock allocation enhances wholesale operations by optimizing inventory distribution based on real-time demand and sales forecasting, reducing overstock and stockouts. Integrating smart inventory systems allows wholesalers to adapt quickly to market fluctuations, ensuring efficient supply chain management and increased profitability.

Real-Time Inventory Analytics

Wholesale operations leveraging smart inventory systems benefit significantly from real-time inventory analytics, enabling precise stock level monitoring and demand forecasting that minimize overstock and stockouts. Integrating advanced data analytics tools allows wholesalers to optimize supply chain efficiency, reduce carrying costs, and respond swiftly to market fluctuations.

Demand Sensing Algorithms

Demand sensing algorithms enhance smart inventory management by analyzing real-time data to predict short-term demand fluctuations more accurately than traditional wholesale methods, reducing stockouts and excess inventory. These algorithms leverage machine learning and advanced analytics to align inventory levels with actual market behavior, optimizing supply chain responsiveness and minimizing carrying costs.

Automated Purchase Order Generation

Automated purchase order generation in wholesale streamlines inventory management by using real-time sales data to predict demand and replenish stock efficiently, reducing human error and stockouts. Smart inventory systems leverage AI algorithms to optimize order quantities and timing, enhancing cash flow and operational agility compared to traditional wholesale methods.

Omnichannel Fulfillment Integration

Wholesale operations benefit from smart inventory systems by enabling real-time inventory visibility across multiple sales channels, streamlining omnichannel fulfillment integration. This synchronization reduces stock discrepancies, accelerates order processing, and enhances customer satisfaction through consistent product availability.

AI-Powered Inventory Optimization

Wholesale businesses leverage AI-powered inventory optimization to enhance demand forecasting accuracy and minimize stockouts, leading to reduced carrying costs and improved cash flow. Smart inventory systems analyze historical sales data and market trends, enabling wholesalers to maintain optimal stock levels and streamline supply chain operations.

SKU Rationalization

Wholesale SKU rationalization streamlines inventory by identifying high-performing products and eliminating low-demand SKUs, reducing carrying costs and improving turnover rates. Smart inventory systems leverage data analytics to optimize SKU assortment, ensuring wholesalers maintain balanced stock levels aligned with market demand for increased profitability.

Just-in-Time Wholesale

Just-in-Time Wholesale optimizes inventory turnover by synchronizing stock arrival with demand, minimizing carrying costs and reducing waste compared to traditional Wholesale methods that often require bulk purchasing and extensive storage. This approach leverages real-time data analytics and supplier coordination to ensure efficient inventory levels and improved cash flow management.

Digital Twin Inventory Management

Wholesale companies leveraging digital twin inventory management gain real-time visibility into stock levels, enabling precise demand forecasting and reducing excess inventory costs. Smart inventory systems enhance wholesale operations by simulating supply chain scenarios, optimizing replenishment cycles, and improving order accuracy through data-driven insights.

Wholesale vs Smart Inventory Infographic

industrydif.com

industrydif.com