Manual inspection in construction involves on-site personnel physically examining structures, which can be time-consuming and pose safety risks. Drone inspection offers a faster, safer alternative by capturing high-resolution aerial images and data for detailed analysis. Utilizing drones enhances accuracy and reduces downtime, making project monitoring more efficient and cost-effective.

Table of Comparison

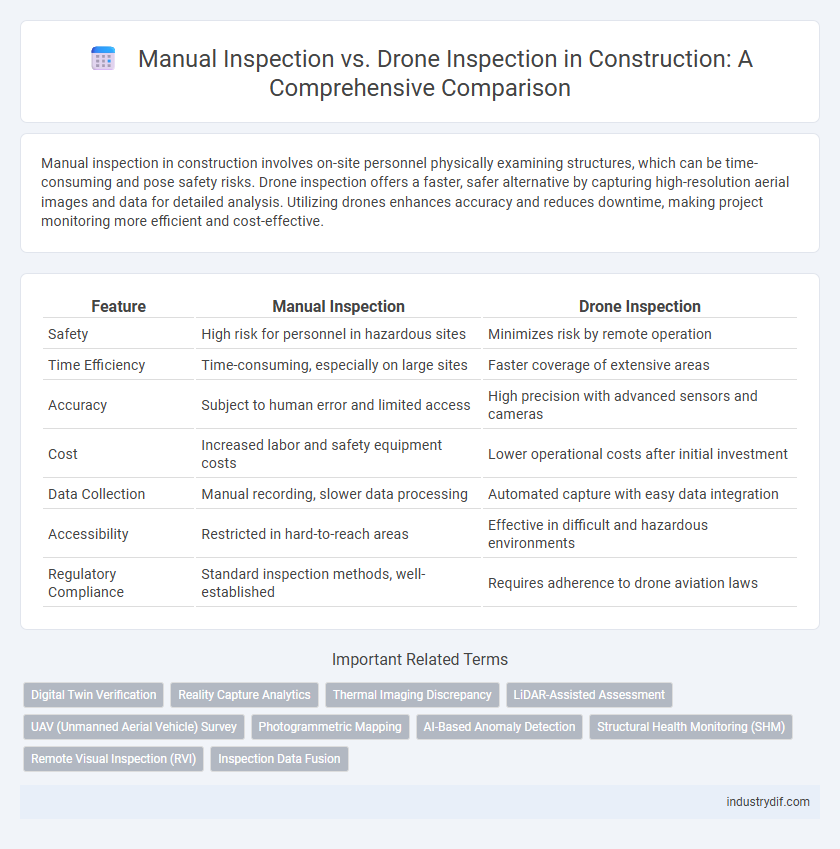

| Feature | Manual Inspection | Drone Inspection |

|---|---|---|

| Safety | High risk for personnel in hazardous sites | Minimizes risk by remote operation |

| Time Efficiency | Time-consuming, especially on large sites | Faster coverage of extensive areas |

| Accuracy | Subject to human error and limited access | High precision with advanced sensors and cameras |

| Cost | Increased labor and safety equipment costs | Lower operational costs after initial investment |

| Data Collection | Manual recording, slower data processing | Automated capture with easy data integration |

| Accessibility | Restricted in hard-to-reach areas | Effective in difficult and hazardous environments |

| Regulatory Compliance | Standard inspection methods, well-established | Requires adherence to drone aviation laws |

Overview of Manual and Drone Inspection in Construction

Manual inspection in construction involves on-site personnel visually examining structures, which can be time-consuming and pose safety risks in hard-to-reach areas. Drone inspection leverages unmanned aerial vehicles equipped with high-resolution cameras and sensors to capture detailed images and data quickly, enhancing accuracy and reducing downtime. Integrating drone technology improves efficiency and safety compared to traditional manual inspection methods.

Key Differences Between Manual and Drone Inspection

Manual inspection in construction often involves physical access to sites, relying on human expertise to identify defects or safety hazards, which can be time-consuming and potentially dangerous. Drone inspection utilizes unmanned aerial vehicles equipped with high-resolution cameras and sensors, offering faster data collection and access to hard-to-reach areas without risking personnel safety. Key differences include efficiency, accuracy, and safety, with drone inspections enabling real-time data analysis and comprehensive site monitoring compared to the subjective and limited scope of manual methods.

Accuracy and Data Collection Capabilities

Manual inspection in construction offers direct human observation, which can identify subtle defects but is limited by accessibility and human error, affecting overall accuracy. Drone inspection provides high-resolution imaging and real-time data capture from multiple angles, enhancing accuracy and comprehensive data collection without risking worker safety. Combining drone technology with advanced sensors and AI analytics significantly improves defect detection rates and project monitoring efficiency.

Safety Considerations on Construction Sites

Manual inspection on construction sites poses significant safety risks due to workers navigating hazardous environments at heights or unstable structures, leading to increased chances of falls and injuries. Drone inspection minimizes these risks by enabling remote monitoring of hard-to-reach areas, reducing worker exposure to dangerous conditions. Incorporating drone technology enhances overall site safety while maintaining detailed visual data for accurate project assessments.

Time Efficiency and Project Timelines

Manual inspection in construction sites typically requires significantly more time due to limited accessibility and the need for safety precautions, often causing delays in project timelines. Drone inspection accelerates data collection by accessing hard-to-reach areas quickly and safely, enabling faster identification of issues and real-time progress monitoring. Utilizing drones can reduce inspection time by up to 70%, directly contributing to improved time efficiency and adherence to stringent project deadlines.

Cost Implications for Construction Projects

Manual inspection in construction projects often incurs higher labor costs and extended project timelines due to the need for on-site personnel and potential safety hazards. Drone inspection significantly reduces these expenses by enabling rapid, high-resolution data collection with fewer workers, minimizing downtime and risk. The upfront investment in drone technology is offset by long-term savings in labor, enhanced accuracy, and faster decision-making processes.

Accessibility to Hard-to-Reach Areas

Drone inspection significantly enhances accessibility to hard-to-reach areas in construction sites by offering aerial views and maneuverability in confined spaces, reducing the need for scaffolding or ladders. Manual inspection often faces limitations due to safety risks and physical constraints when accessing elevated structures, rooftops, or complex frameworks. Utilizing drones accelerates data collection and improves safety, enabling comprehensive assessments of areas previously inaccessible or hazardous for human inspectors.

Environmental Impact and Sustainability

Manual inspection in construction sites often involves significant resource use, including fuel consumption for vehicles and extensive manpower, leading to higher carbon emissions and environmental disturbance. Drone inspections reduce the environmental impact by minimizing the need for heavy machinery and transportation, lowering greenhouse gas emissions and energy consumption. Using drones promotes sustainability by enabling more frequent, precise monitoring, which helps identify and mitigate potential environmental hazards early in the construction process.

Case Studies: Success Stories in Manual vs Drone Inspection

Case studies reveal that drone inspections in construction projects reduce inspection times by up to 70%, enhancing safety by minimizing worker exposure to hazardous areas. Manual inspections remain critical for detailed structural assessments but often take twice as long and incur higher labor costs. Successful projects demonstrate drones complement manual methods, delivering comprehensive data for improved decision-making and project efficiency.

Future Trends in Construction Inspection Technologies

Manual inspection remains labor-intensive and subject to human error, while drone inspection leverages automation, high-resolution imaging, and real-time data analytics to enhance accuracy and efficiency. Emerging trends include integrating AI-powered image recognition and 3D modeling to detect structural defects and progress deviations faster than traditional methods. Future construction inspection technologies will increasingly rely on autonomous drones equipped with sensors and machine learning algorithms to provide predictive maintenance and ensure safety compliance.

Related Important Terms

Digital Twin Verification

Manual inspection relies on human observation for Digital Twin verification, often leading to slower data collection and potential errors in complex construction environments. Drone inspection accelerates data acquisition with high-resolution imaging and real-time 3D modeling, enhancing the accuracy and efficiency of Digital Twin updates in construction projects.

Reality Capture Analytics

Manual inspection in construction relies on traditional methods that are time-consuming and prone to human error, limiting the accuracy of reality capture analytics. Drone inspection leverages high-resolution aerial imagery and 3D mapping technology to deliver precise, real-time data for enhanced construction site analysis and decision-making.

Thermal Imaging Discrepancy

Manual inspection of thermal imaging in construction often results in subjective interpretation and limited coverage, leading to potential discrepancies in detecting heat loss or moisture intrusion. Drone inspection utilizes advanced thermal cameras to provide precise, comprehensive, and high-resolution thermal data, improving accuracy in identifying discrepancies and enabling faster decision-making on-site.

LiDAR-Assisted Assessment

LiDAR-assisted assessment in drone inspection provides high-resolution 3D mapping and precise measurement capabilities that surpass traditional manual inspection accuracy and efficiency on construction sites. This technology enables rapid detection of structural anomalies and real-time data collection, significantly reducing human error and enhancing safety compliance.

UAV (Unmanned Aerial Vehicle) Survey

UAV survey technology enhances construction site inspections by providing high-resolution aerial imagery and real-time data, enabling precise mapping and progress tracking. Manual inspections often face limitations in safety, accessibility, and time efficiency, whereas drone inspections offer rapid deployment, cost reduction, and comprehensive site coverage.

Photogrammetric Mapping

Manual inspection in construction relies on direct human observation, limiting photogrammetric mapping accuracy due to accessibility constraints and slower data collection. Drone inspection enhances photogrammetric mapping by capturing high-resolution images from multiple angles rapidly, enabling precise 3D models and comprehensive site analysis with improved safety and efficiency.

AI-Based Anomaly Detection

AI-based anomaly detection in drone inspections enhances construction site safety by quickly identifying structural defects and irregularities that manual inspections might overlook, increasing accuracy and efficiency. Drones equipped with advanced sensors and AI algorithms provide real-time data analysis, reducing human error and enabling proactive maintenance in complex construction environments.

Structural Health Monitoring (SHM)

Manual inspection for Structural Health Monitoring (SHM) in construction provides detailed, hands-on assessment but is time-consuming and limited in accessing hard-to-reach areas. Drone inspection enhances SHM efficiency by capturing high-resolution images and real-time data from complex structures, enabling rapid detection of defects and structural anomalies with improved safety and reduced labor costs.

Remote Visual Inspection (RVI)

Remote Visual Inspection (RVI) using drones enhances construction site safety and accuracy by capturing high-resolution images and real-time video of hard-to-reach areas, reducing the need for manual inspection in hazardous environments. This technology accelerates project timelines and improves defect detection through detailed aerial views, enabling proactive maintenance and quality assurance.

Inspection Data Fusion

Inspection data fusion combines high-resolution aerial imagery from drones with detailed ground-level observations obtained through manual inspection, enhancing the accuracy and comprehensiveness of construction site assessments. This integration enables real-time analysis and detection of structural issues, optimizing decision-making and improving overall project safety and quality control.

Manual Inspection vs Drone Inspection Infographic

industrydif.com

industrydif.com