Rebar and glass fiber reinforced polymer (GFRP) serve as essential reinforcement materials in construction, each offering distinct advantages. Rebar, made of steel, provides high tensile strength and excellent bonding with concrete, ensuring structural stability in heavy-load applications. GFRP offers corrosion resistance and lightweight properties, making it ideal for environments prone to moisture or chemical exposure while reducing long-term maintenance costs.

Table of Comparison

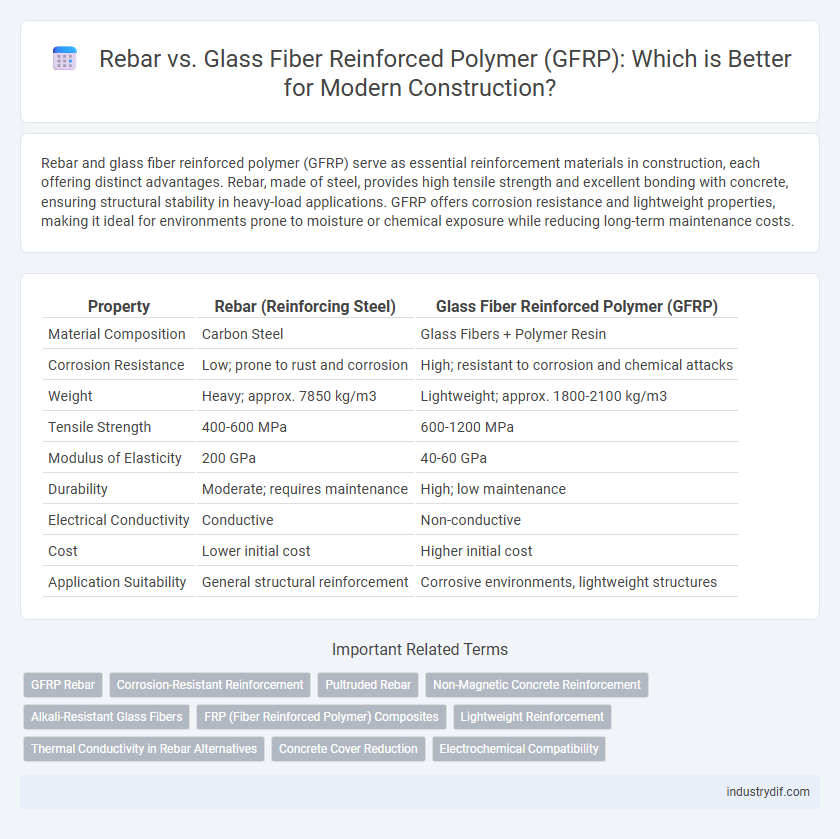

| Property | Rebar (Reinforcing Steel) | Glass Fiber Reinforced Polymer (GFRP) |

|---|---|---|

| Material Composition | Carbon Steel | Glass Fibers + Polymer Resin |

| Corrosion Resistance | Low; prone to rust and corrosion | High; resistant to corrosion and chemical attacks |

| Weight | Heavy; approx. 7850 kg/m3 | Lightweight; approx. 1800-2100 kg/m3 |

| Tensile Strength | 400-600 MPa | 600-1200 MPa |

| Modulus of Elasticity | 200 GPa | 40-60 GPa |

| Durability | Moderate; requires maintenance | High; low maintenance |

| Electrical Conductivity | Conductive | Non-conductive |

| Cost | Lower initial cost | Higher initial cost |

| Application Suitability | General structural reinforcement | Corrosive environments, lightweight structures |

Introduction to Rebar and Glass Fiber Reinforced Polymer

Rebar, typically made of steel, serves as a fundamental reinforcement material in concrete construction due to its high tensile strength and durability. Glass Fiber Reinforced Polymer (GFRP) is a composite material composed of glass fibers embedded in a polymer matrix, offering corrosion resistance and lightweight properties. Both materials enhance structural performance, with rebar excelling in traditional load-bearing applications and GFRP providing advantages in corrosive environments and specialized designs.

Material Composition: Rebar vs GFRP

Rebar is primarily composed of steel, offering high tensile strength and ductility essential for reinforced concrete structures. Glass Fiber Reinforced Polymer (GFRP) consists of glass fibers embedded in a polymer matrix, providing corrosion resistance and lightweight properties. The distinct composition influences their performance, durability, and suitability in different construction environments.

Strength and Durability Comparison

Rebar typically offers higher tensile strength, ranging from 400 to 600 MPa, while Glass Fiber Reinforced Polymer (GFRP) exhibits tensile strengths between 800 and 1200 MPa, making GFRP generally stronger under tension. Durability-wise, GFRP resists corrosion from chemicals, moisture, and salts far better than traditional steel rebar, which is prone to rust and degradation in harsh environments. The non-corrosive nature of GFRP extends the service life of reinforced concrete structures, particularly in marine or chemically aggressive settings.

Corrosion Resistance: Steel Rebar vs GFRP

Steel rebar is highly susceptible to corrosion, especially in environments exposed to moisture, chlorides, and chemicals, leading to structural degradation over time. Glass Fiber Reinforced Polymer (GFRP) offers superior corrosion resistance due to its non-metallic composition, preventing rust and extending the lifespan of concrete structures. This resistance makes GFRP an ideal choice for marine, bridge, and infrastructure projects where durability against corrosive agents is critical.

Weight and Ease of Handling

Rebar typically weighs significantly more than Glass Fiber Reinforced Polymer (GFRP), which makes GFRP easier to transport and maneuver on construction sites. The lower weight of GFRP reduces labor costs and increases efficiency during installation, especially in large-scale projects requiring extensive reinforcement. Its lightweight nature also minimizes structural load, offering advantages in seismic-prone or weight-sensitive applications.

Installation Techniques and Challenges

Rebar installation requires precise bending and tying to form a steel framework that ensures structural integrity, often demanding skilled labor and heavy equipment for placement in concrete. Glass Fiber Reinforced Polymer (GFRP) offers lighter, corrosion-resistant reinforcement and uses adhesive bonding or mechanical anchoring, but challenges arise from its sensitivity to UV exposure and complex joining methods. Both materials require careful handling: rebar's weight complicates installation, while GFRP demands specialized tools for cutting and fastening, affecting overall project timelines and costs.

Cost Analysis: Initial and Long-term

Rebar typically involves lower initial costs due to its widespread availability and established manufacturing processes, while Glass Fiber Reinforced Polymer (GFRP) demands higher upfront investment because of advanced material technology and specialized installation. Over the long term, GFRP offers cost savings through superior corrosion resistance, reduced maintenance expenses, and extended service life in harsh environments compared to traditional steel rebar. Life cycle cost analysis reveals that despite higher initial prices, GFRP can be more economical for infrastructure projects exposed to aggressive chemical or marine conditions.

Applications in Construction Projects

Rebar remains the standard for reinforcing concrete in heavy-load construction projects such as bridges, high-rise buildings, and highways due to its superior tensile strength and cost-effectiveness. Glass Fiber Reinforced Polymer (GFRP) is increasingly utilized in corrosive environments like marine structures, parking garages, and chemical plants, offering exceptional corrosion resistance and lightweight properties. Both materials serve crucial roles, with rebar favored for structural durability and GFRP selected for longevity in aggressive conditions.

Environmental Impact and Sustainability

Glass Fiber Reinforced Polymer (GFRP) rebar offers superior corrosion resistance, significantly reducing the need for repairs and replacements compared to traditional steel rebar, which often corrodes and deteriorates in moist environments. The production of GFRP involves less energy consumption and emits fewer greenhouse gases than steel manufacturing, contributing to lower carbon footprints in construction projects. Sustainable construction practices favor GFRP for its durability, reduced material waste, and enhanced lifecycle performance, making it an environmentally responsible choice over conventional rebar.

Future Trends in Reinforcement Materials

Future trends in reinforcement materials highlight a growing shift from traditional steel rebar to Glass Fiber Reinforced Polymer (GFRP) due to its superior corrosion resistance and lightweight properties. Advances in nanotechnology and composite manufacturing are enhancing the durability and mechanical performance of GFRP, making it a viable alternative in infrastructure projects exposed to harsh environments. Sustainability considerations and lifecycle cost analysis increasingly favor GFRP, driving its adoption in bridge decks, marine structures, and seismic retrofitting applications.

Related Important Terms

GFRP Rebar

Glass Fiber Reinforced Polymer (GFRP) rebar offers superior corrosion resistance compared to traditional steel rebar, making it ideal for structures exposed to harsh environmental conditions such as marine or chemical-rich settings. Its lightweight composition and high tensile strength enhance durability and simplify handling, reducing installation time and long-term maintenance costs in construction projects.

Corrosion-Resistant Reinforcement

Corrosion-resistant reinforcement significantly enhances the durability of concrete structures by preventing rust-related deterioration. Glass Fiber Reinforced Polymer (GFRP) outperforms traditional steel rebar in highly corrosive environments due to its non-metallic composition and excellent resistance to chemical and chloride-induced corrosion.

Pultruded Rebar

Pultruded rebar, a type of Glass Fiber Reinforced Polymer (GFRP), offers superior corrosion resistance and higher tensile strength compared to traditional steel rebar, making it ideal for coastal and chemically aggressive environments. Its lightweight properties reduce transportation and handling costs while maintaining structural integrity in reinforced concrete applications.

Non-Magnetic Concrete Reinforcement

Glass Fiber Reinforced Polymer (GFRP) offers a non-magnetic alternative to traditional steel rebar, making it ideal for applications requiring electromagnetic transparency, such as MRI rooms and sensitive electronic facilities. GFRP provides corrosion resistance and high tensile strength, enhancing concrete durability without interference in magnetic fields, unlike conventional steel reinforcement.

Alkali-Resistant Glass Fibers

Alkali-resistant glass fibers used in Glass Fiber Reinforced Polymer (GFRP) significantly enhance durability and corrosion resistance compared to traditional steel rebar, particularly in high-alkaline concrete environments. This makes GFRP an optimal choice for reinforcing structures exposed to harsh chemical conditions, extending service life and reducing maintenance costs.

FRP (Fiber Reinforced Polymer) Composites

Fiber Reinforced Polymer (FRP) composites, including Glass Fiber Reinforced Polymer (GFRP), offer superior corrosion resistance, lightweight properties, and high tensile strength compared to traditional steel rebar, making them ideal for enhancing durability and lifespan in concrete structures. The non-conductive nature and ease of installation of FRP composites reduce maintenance costs and improve structural performance in harsh or corrosive environments such as marine and chemical exposure zones.

Lightweight Reinforcement

Glass Fiber Reinforced Polymer (GFRP) offers a significant weight reduction compared to traditional steel rebar, with densities around 1.9 to 2.0 g/cm3 versus steel's 7.85 g/cm3, enhancing ease of handling and reducing transportation costs in construction projects. This lightweight reinforcement also improves corrosion resistance and durability, making GFRP an optimal choice for structures exposed to harsh environmental conditions.

Thermal Conductivity in Rebar Alternatives

Rebar exhibits higher thermal conductivity compared to glass fiber reinforced polymer (GFRP), making GFRP a superior choice for applications requiring thermal insulation alongside structural reinforcement. The low thermal conductivity of GFRP reduces heat transfer in concrete structures, enhancing energy efficiency and durability under temperature fluctuations.

Concrete Cover Reduction

Glass Fiber Reinforced Polymer (GFRP) rebar allows for a significant reduction in concrete cover due to its high corrosion resistance compared to traditional steel rebar, which requires thicker cover to prevent rust and structural damage. This reduction enhances structural efficiency and durability while reducing material costs and increasing usable space in construction projects.

Electrochemical Compatibility

Rebar made of steel demonstrates high electrochemical compatibility with concrete due to its ability to form a passive oxide layer that prevents corrosion, whereas Glass Fiber Reinforced Polymer (GFRP) exhibits superior corrosion resistance by being inert and non-conductive, eliminating the risk of electrochemical reactions. GFRP's electrochemical inertness ensures long-term durability in aggressive environments, making it ideal for structures exposed to chloride ions or acidic conditions where steel rebar may deteriorate.

Rebar vs Glass Fiber Reinforced Polymer Infographic

industrydif.com

industrydif.com