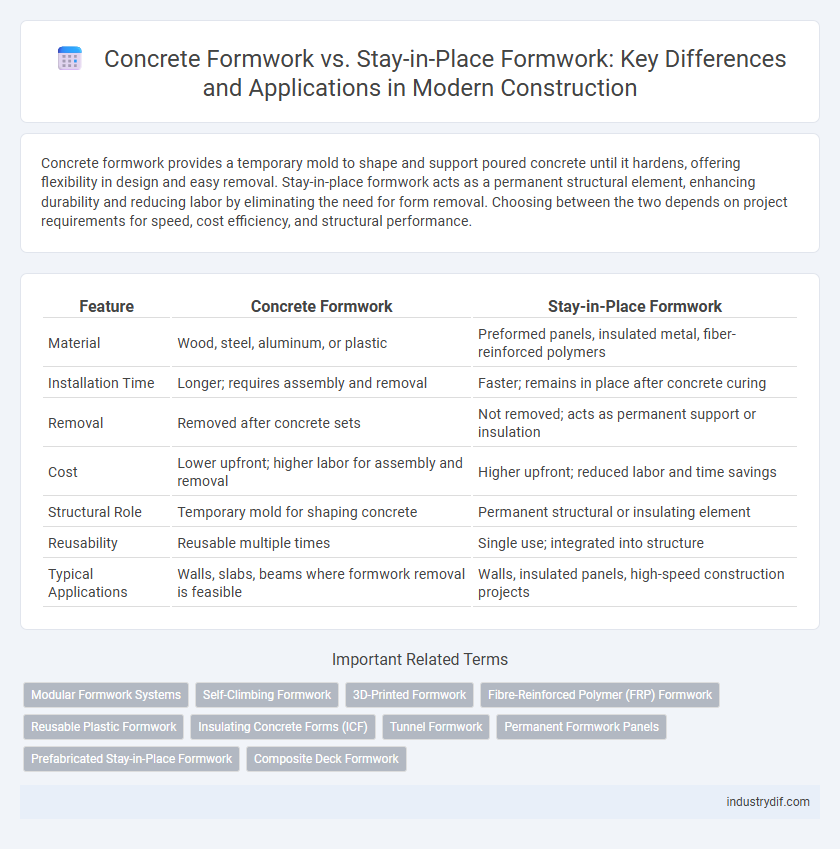

Concrete formwork provides a temporary mold to shape and support poured concrete until it hardens, offering flexibility in design and easy removal. Stay-in-place formwork acts as a permanent structural element, enhancing durability and reducing labor by eliminating the need for form removal. Choosing between the two depends on project requirements for speed, cost efficiency, and structural performance.

Table of Comparison

| Feature | Concrete Formwork | Stay-in-Place Formwork |

|---|---|---|

| Material | Wood, steel, aluminum, or plastic | Preformed panels, insulated metal, fiber-reinforced polymers |

| Installation Time | Longer; requires assembly and removal | Faster; remains in place after concrete curing |

| Removal | Removed after concrete sets | Not removed; acts as permanent support or insulation |

| Cost | Lower upfront; higher labor for assembly and removal | Higher upfront; reduced labor and time savings |

| Structural Role | Temporary mold for shaping concrete | Permanent structural or insulating element |

| Reusability | Reusable multiple times | Single use; integrated into structure |

| Typical Applications | Walls, slabs, beams where formwork removal is feasible | Walls, insulated panels, high-speed construction projects |

Overview of Concrete Formwork

Concrete formwork serves as the temporary or permanent molds into which concrete is poured and shaped during construction projects. This process involves using materials such as timber, steel, or plastic to create precise frameworks that support the concrete until it cures and gains sufficient strength. Properly designed concrete formwork ensures structural integrity, surface finish quality, and ease of removal or integration with stay-in-place systems.

Introduction to Stay-in-Place Formwork

Stay-in-place formwork consists of permanent molds left in place after concrete is poured, providing structural support and eliminating the need for removal. Common materials include metal, plastic, and fiber-reinforced composites, enhancing durability and thermal insulation in concrete structures. This method offers faster construction times and improved safety compared to traditional removable concrete formwork.

Key Differences Between Conventional and Stay-in-Place Formwork

Conventional concrete formwork is typically made from timber, steel, or plywood and is removed after the concrete sets, allowing for reuse but requiring labor-intensive stripping. Stay-in-place formwork, often composed of insulated metal or fiber-reinforced polymers, remains embedded in the structure, providing thermal insulation and additional structural support. The key differences lie in material composition, removal process, and performance benefits, with stay-in-place formwork enhancing durability and reducing construction time compared to conventional methods.

Material Types Used in Formwork Systems

Concrete formwork primarily utilizes timber, steel, aluminum, and plywood for temporary molds that shape and support concrete until it cures. Stay-in-place formwork systems often incorporate composite materials, corrugated steel, and insulating panels, serving both as structural support and permanent parts of the finished structure. Material selection impacts durability, cost, and thermal insulation properties, influencing the choice between conventional and stay-in-place formwork solutions in construction projects.

Installation Processes: Traditional vs. Stay-in-Place

Traditional concrete formwork installation involves assembling and securing reusable panels or timber on-site, requiring extensive labor for setup and removal after the concrete cures. Stay-in-place formwork integrates into the structure as a permanent part of the concrete element, eliminating the need for formwork removal and accelerating project timelines. The stay-in-place method typically reduces labor costs and enhances safety by minimizing on-site handling and demolition activities.

Time and Cost Implications of Each Method

Concrete formwork demands extensive labor and time for assembly and removal, increasing overall construction duration and labor costs. Stay-in-place formwork, often made of lightweight materials like steel or plastic, accelerates construction by eliminating the removal phase, reducing labor expenses and shortening project timelines. Although initial material costs for stay-in-place formwork are higher, the time savings and reduced labor requirements often lead to lower total project costs compared to traditional formwork methods.

Structural Performance and Durability

Concrete formwork provides robust temporary support ensuring precise shaping during curing, whereas stay-in-place formwork integrates permanently with the structure, enhancing overall durability by acting as permanent reinforcement. Stay-in-place formwork reduces labor costs and construction time while offering improved resistance to environmental degradation. Both systems contribute differently to structural performance, with stay-in-place formwork increasing load-bearing capacity and long-term stability.

Sustainability and Environmental Considerations

Concrete formwork typically involves temporary materials like timber or plywood, which generate significant construction waste and require energy-intensive production processes. Stay-in-place formwork, often made from recyclable or reusable materials such as steel or insulated panels, minimizes waste and reduces environmental impact by serving both as formwork and part of the finished structure. Selecting stay-in-place formwork enhances sustainability by improving resource efficiency, lowering carbon emissions from material production, and facilitating better thermal performance in energy-efficient buildings.

Applications in Modern Construction Projects

Concrete formwork provides temporary molds for shaping concrete, enabling flexibility in complex architectural designs and facilitating high-strength structural elements like beams and slabs. Stay-in-place formwork, often used in high-rise buildings and bridge construction, serves as permanent reinforcement and protective layers, improving durability and reducing labor costs by eliminating the need for removal. Both methods are integral in modern projects, with stay-in-place formwork favored for faster construction timelines and enhanced safety in repetitive, large-scale developments.

Future Trends in Formwork Technology

Emerging trends in concrete formwork emphasize automation and sustainable materials, with stay-in-place formwork integrating smart sensors for real-time structural health monitoring. Advances in 3D printing and modular formwork systems aim to reduce labor costs and construction time while enhancing precision and durability. Future formwork technology will likely prioritize recyclable composites and adaptive designs to meet evolving environmental regulations and complex architectural demands.

Related Important Terms

Modular Formwork Systems

Modular formwork systems in concrete construction offer enhanced efficiency and reusability compared to stay-in-place formwork, enabling rapid assembly and consistent quality in forming structural elements. These systems, composed of prefabricated panels and standardized components, reduce labor costs and minimize material waste while ensuring precise dimensions and surface finishes for concrete structures.

Self-Climbing Formwork

Self-climbing formwork, a type of stay-in-place formwork, offers enhanced efficiency in high-rise construction by automatically ascending as the concrete sets, reducing labor costs and improving safety compared to traditional concrete formwork. This system integrates hydraulic jacks allowing continuous vertical progression without dismantling, optimizing cycle times for casting walls and cores in multi-story buildings.

3D-Printed Formwork

3D-printed formwork offers enhanced precision and design flexibility compared to traditional concrete formwork and stay-in-place formwork, enabling complex geometries with reduced material waste. This innovative technique accelerates construction timelines and improves surface quality while minimizing labor costs and environmental impact.

Fibre-Reinforced Polymer (FRP) Formwork

Fibre-Reinforced Polymer (FRP) formwork offers enhanced durability and corrosion resistance compared to traditional concrete formwork, making it ideal for stay-in-place formwork applications in harsh environments. Its lightweight properties and high strength-to-weight ratio reduce labor costs and installation time while providing superior structural support during the curing process.

Reusable Plastic Formwork

Reusable plastic formwork offers significant advantages over traditional concrete formwork and stay-in-place formwork by providing lightweight, durable, and easy-to-clean panels that support multiple construction cycles, reducing material waste and labor costs. Its interlocking design ensures precise alignment and uniform concrete curing, enhancing structural integrity while accelerating project timelines in various construction applications.

Insulating Concrete Forms (ICF)

Insulating Concrete Forms (ICF) provide superior thermal insulation and energy efficiency compared to traditional concrete formwork by acting as both formwork and permanent insulation. ICF systems reduce construction time and labor costs while enhancing structural strength and airtightness in residential and commercial building projects.

Tunnel Formwork

Tunnel formwork, a specialized type of stay-in-place formwork, integrates both wall and slab casting in a single operation, significantly accelerating construction cycles while enhancing structural accuracy and durability. Unlike traditional concrete formwork, tunnel formwork remains on site as a permanent mold, reducing labor costs and improving overall project efficiency in large-scale infrastructure projects such as tunnels and underground passages.

Permanent Formwork Panels

Permanent formwork panels, commonly known as stay-in-place formwork, serve as both the mold for concrete placement and a lasting structural component, enhancing construction speed and reducing labor costs. These panels, typically made from materials such as steel, plastic, or fiber-reinforced composites, provide durability, thermal insulation, and improved load-bearing capacity within concrete structures.

Prefabricated Stay-in-Place Formwork

Prefabricated stay-in-place formwork is a modern construction solution offering enhanced durability, faster installation, and reduced labor costs compared to traditional concrete formwork. This system integrates factory-made materials such as steel or fiber-reinforced polymers that remain embedded in the concrete, improving structural integrity and minimizing waste on site.

Composite Deck Formwork

Composite deck formwork integrates stay-in-place formwork with reinforcement and concrete slabs to create a structural composite system that reduces construction time and labor costs. Unlike traditional concrete formwork, this permanent formwork remains in place, providing long-term support and enhancing slab performance through composite action.

Concrete Formwork vs Stay-in-Place Formwork Infographic

industrydif.com

industrydif.com