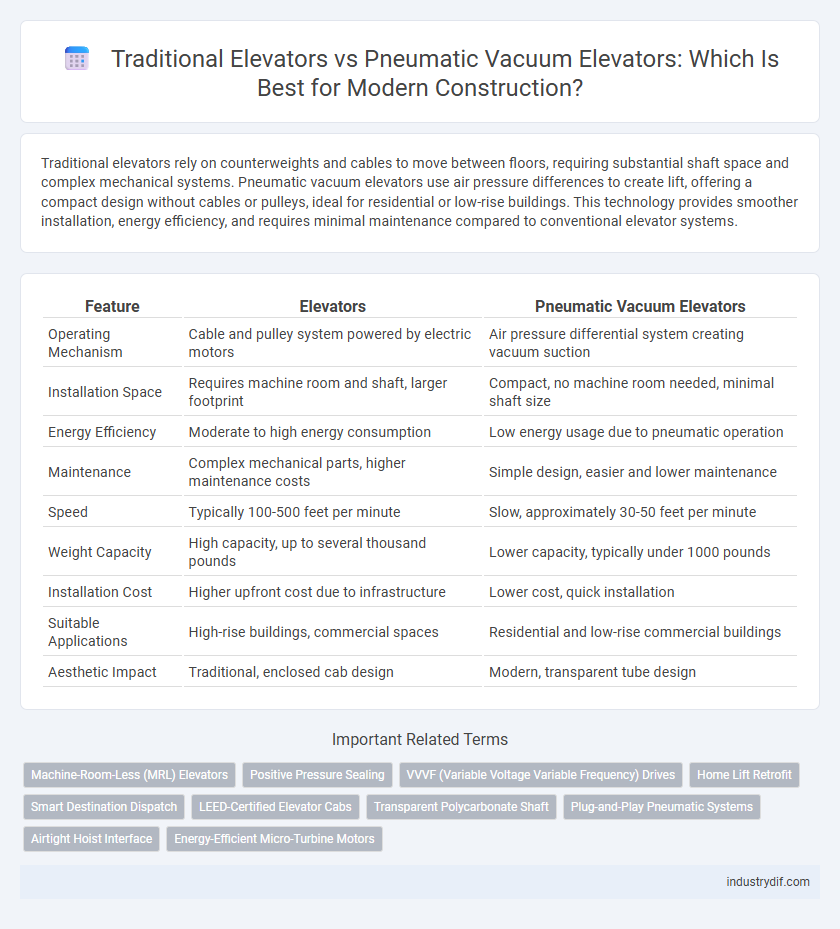

Traditional elevators rely on counterweights and cables to move between floors, requiring substantial shaft space and complex mechanical systems. Pneumatic vacuum elevators use air pressure differences to create lift, offering a compact design without cables or pulleys, ideal for residential or low-rise buildings. This technology provides smoother installation, energy efficiency, and requires minimal maintenance compared to conventional elevator systems.

Table of Comparison

| Feature | Elevators | Pneumatic Vacuum Elevators |

|---|---|---|

| Operating Mechanism | Cable and pulley system powered by electric motors | Air pressure differential system creating vacuum suction |

| Installation Space | Requires machine room and shaft, larger footprint | Compact, no machine room needed, minimal shaft size |

| Energy Efficiency | Moderate to high energy consumption | Low energy usage due to pneumatic operation |

| Maintenance | Complex mechanical parts, higher maintenance costs | Simple design, easier and lower maintenance |

| Speed | Typically 100-500 feet per minute | Slow, approximately 30-50 feet per minute |

| Weight Capacity | High capacity, up to several thousand pounds | Lower capacity, typically under 1000 pounds |

| Installation Cost | Higher upfront cost due to infrastructure | Lower cost, quick installation |

| Suitable Applications | High-rise buildings, commercial spaces | Residential and low-rise commercial buildings |

| Aesthetic Impact | Traditional, enclosed cab design | Modern, transparent tube design |

Introduction to Elevator Systems in Construction

Elevator systems in construction primarily consist of traditional traction and hydraulic elevators, offering reliable vertical transportation through mechanical components such as cables and counterweights. Pneumatic vacuum elevators represent an innovative alternative, utilizing air pressure differentials to move the cab smoothly within a cylindrical shaft without the need for cables or pulleys. These vacuum elevators provide energy-efficient operation, compact installation footprint, and reduced structural modifications compared to conventional elevator systems.

Overview of Traditional Elevators

Traditional elevators rely on a system of cables, pulleys, and counterweights powered by electric motors to transport passengers and goods between floors. These elevators require substantial shaft space, a machine room, and regular maintenance to ensure safety and performance. Their widespread use in commercial and residential buildings underscores their reliability and ability to accommodate heavy loads and high traffic volumes.

What Are Pneumatic Vacuum Elevators?

Pneumatic vacuum elevators use air pressure differences to move the cab vertically within a transparent cylindrical shaft, eliminating the need for cables or counterweights. These elevators are energy-efficient, require minimal space, and are easier to install in both new builds and retrofits compared to traditional traction or hydraulic elevators. Their design enhances safety by automatically locking the cab in place if pressure is lost.

Installation Requirements: Traditional vs Pneumatic Vacuum Elevators

Traditional elevators demand extensive shaft construction, machine rooms, and reinforced structural support, making installation complex and time-consuming. Pneumatic vacuum elevators require minimal space with no pit or machine room, relying on lightweight materials and modular components for easier, faster installation. These differences significantly impact project timelines and structural alterations in building design.

Space Efficiency: Comparing Elevator Types

Traditional elevators require substantial shaft space and machine rooms, limiting their installation in buildings with confined area. Pneumatic vacuum elevators use a compact, self-supporting cylindrical design that eliminates the need for extensive shafts or counterweights, maximizing usable floor space. This space-efficient technology is particularly advantageous in residential and small commercial projects where preserving square footage is critical.

Energy Consumption and Sustainability

Pneumatic vacuum elevators consume significantly less energy than traditional traction elevators, using air pressure differences to move the cabin with minimal electricity. Their energy-efficient design reduces carbon footprint and contributes to sustainable building practices by lowering operational costs and environmental impact. Traditional elevators often require continuous power for motors and hydraulic systems, making pneumatic vacuum elevators a greener choice for eco-conscious construction projects.

Safety Features and Regulatory Compliance

Elevators incorporate advanced safety features such as emergency brakes, overload sensors, and fire-resistant materials, meeting strict International Building Code (IBC) and ASME A17.1 standards. Pneumatic vacuum elevators use a sealed, transparent tube design with vacuum-powered lift systems, which inherently eliminate the risk of cables snapping and comply with UL 325 elevator safety regulations. Both types require rigorous inspection protocols to ensure passenger safety and adherence to local building codes and ADA accessibility requirements.

Maintenance and Longevity Considerations

Traditional elevators require regular mechanical maintenance involving cables, pulleys, and motors to ensure safety and performance, often resulting in higher long-term service costs. Pneumatic vacuum elevators feature fewer moving parts and a self-lubricating mechanism, reducing maintenance frequency and downtime while extending equipment lifespan. Longevity for pneumatic systems is enhanced by corrosion-resistant materials and sealed cabins, minimizing wear from environmental factors compared to conventional elevator components.

Cost Analysis: Initial Investment and Lifecycle

Elevators typically require a higher initial investment due to extensive shaft construction and mechanical system installation, whereas pneumatic vacuum elevators have lower upfront costs with simplified shaft requirements and plug-and-play design. Lifecycle expenses for traditional elevators often include comprehensive maintenance of cables, motors, and hydraulic systems, while pneumatic vacuum elevators benefit from fewer moving parts, reducing maintenance frequency and overall operational costs. Evaluating total cost of ownership reveals that pneumatic vacuum elevators can offer significant savings over time, especially in residential or low-rise applications.

Choosing the Right Elevator Solution for Your Project

Selecting the right elevator solution depends on factors such as building height, space availability, and budget constraints. Traditional elevators excel in high-rise applications with heavy traffic, offering robust capacity and speed, while pneumatic vacuum elevators provide compact design, energy efficiency, and ease of installation for low to mid-rise buildings. Evaluating project-specific requirements, including load capacity, shaft dimensions, and maintenance needs, ensures optimal elevator performance and cost-effectiveness.

Related Important Terms

Machine-Room-Less (MRL) Elevators

Machine-Room-Less (MRL) elevators offer significant space-saving advantages over traditional pneumatic vacuum elevators by eliminating the need for a separate machine room, which reduces building construction costs and optimizes usable floor area. MRL elevators also provide enhanced energy efficiency and smoother ride quality through gearless traction systems, making them ideal for both residential and commercial construction projects where architectural flexibility and sustainability are priorities.

Positive Pressure Sealing

Elevators with traditional mechanical sealing systems rely on tight physical barriers to prevent air infiltration, while pneumatic vacuum elevators utilize positive pressure sealing that creates a pressurized environment to enhance energy efficiency and reduce noise. Positive pressure sealing in pneumatic vacuum elevators ensures smoother cabin operation by minimizing air leakage and maintaining consistent pressure differentials within the shaft.

VVVF (Variable Voltage Variable Frequency) Drives

VVVF (Variable Voltage Variable Frequency) drives deliver precise motor speed control and energy efficiency in traditional elevators, enabling smooth acceleration and deceleration while reducing power consumption and mechanical stress. Pneumatic vacuum elevators, typically powered by air pressure differentials, do not utilize VVVF technology, resulting in simpler operation but less energy optimization and limited control over speed variations.

Home Lift Retrofit

Pneumatic vacuum elevators offer a space-saving, non-invasive home lift retrofit solution with minimal structural alterations compared to traditional elevator systems, making them ideal for residential upgrades. Their modular design, energy efficiency, and ease of installation enhance property value while providing smooth vertical transportation within existing building frameworks.

Smart Destination Dispatch

Smart Destination Dispatch systems in traditional elevators optimize passenger flow by grouping riders traveling to the same floors, reducing wait and travel times significantly. Pneumatic vacuum elevators, while energy-efficient and compact, typically lack advanced destination dispatch technology, making them less effective in handling high-traffic or multi-user environments.

LEED-Certified Elevator Cabs

LEED-certified elevator cabs prioritize sustainable materials, energy efficiency, and low environmental impact, with traditional elevators typically using regenerative drives and efficient motors to reduce energy consumption. Pneumatic vacuum elevators offer a unique eco-friendly solution by eliminating the need for a machine room, using air pressure for operation, consuming less electricity, and contributing to LEED certification through reduced material usage and enhanced energy savings.

Transparent Polycarbonate Shaft

Transparent polycarbonate shafts in pneumatic vacuum elevators offer enhanced durability, impact resistance, and a modern aesthetic compared to traditional elevator shafts that typically use glass or metal. The lightweight polycarbonate material reduces structural load while providing clear visibility and excellent resistance to weather and UV radiation, making it ideal for both residential and commercial construction projects.

Plug-and-Play Pneumatic Systems

Plug-and-play pneumatic vacuum elevators offer rapid installation without major structural modifications, making them ideal for retrofit projects and limited space applications, unlike traditional construction-intensive elevator systems. Their vacuum-powered operation eliminates the need for cables, pulleys, and machine rooms, resulting in energy efficiency and lower maintenance costs in residential and commercial buildings.

Airtight Hoist Interface

Elevators with airtight hoist interfaces enhance energy efficiency by minimizing air leakage, whereas pneumatic vacuum elevators inherently rely on pressure differentials without requiring a sealed hoist system. The airtight hoist interface in conventional elevators supports better climate control and noise reduction compared to the open design of pneumatic vacuum elevators.

Energy-Efficient Micro-Turbine Motors

Energy-efficient micro-turbine motors in pneumatic vacuum elevators consume significantly less electricity compared to traditional elevator systems by utilizing vacuum pressure for vertical movement. These advanced motors optimize energy use through low power consumption and reduced mechanical complexity, making pneumatic vacuum elevators a sustainable choice in modern construction.

Elevators vs Pneumatic Vacuum Elevators Infographic

industrydif.com

industrydif.com