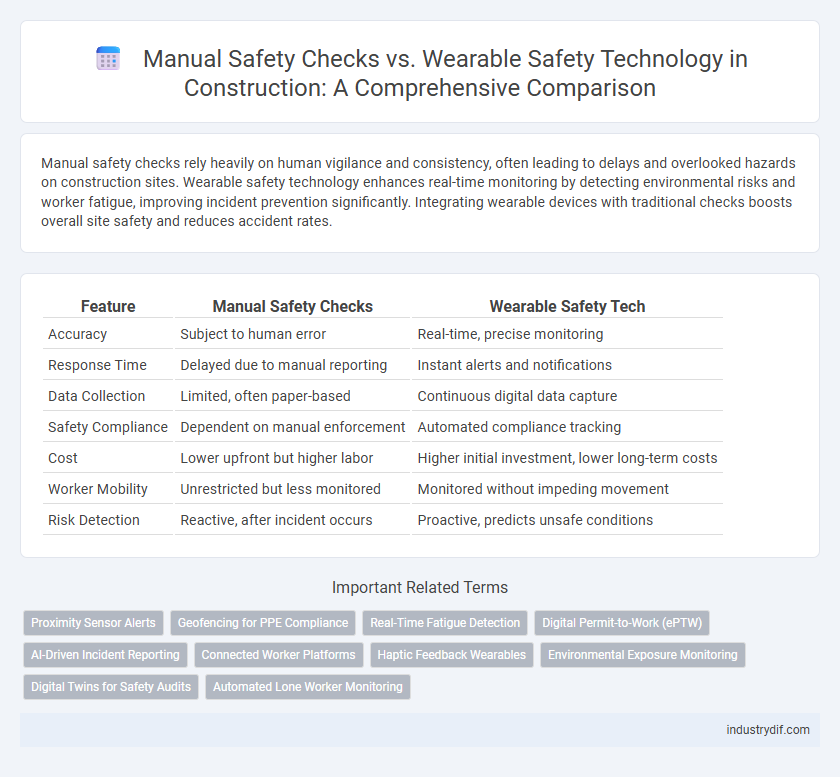

Manual safety checks rely heavily on human vigilance and consistency, often leading to delays and overlooked hazards on construction sites. Wearable safety technology enhances real-time monitoring by detecting environmental risks and worker fatigue, improving incident prevention significantly. Integrating wearable devices with traditional checks boosts overall site safety and reduces accident rates.

Table of Comparison

| Feature | Manual Safety Checks | Wearable Safety Tech |

|---|---|---|

| Accuracy | Subject to human error | Real-time, precise monitoring |

| Response Time | Delayed due to manual reporting | Instant alerts and notifications |

| Data Collection | Limited, often paper-based | Continuous digital data capture |

| Safety Compliance | Dependent on manual enforcement | Automated compliance tracking |

| Cost | Lower upfront but higher labor | Higher initial investment, lower long-term costs |

| Worker Mobility | Unrestricted but less monitored | Monitored without impeding movement |

| Risk Detection | Reactive, after incident occurs | Proactive, predicts unsafe conditions |

Introduction to Safety Protocols in Construction

Manual safety checks involve routine inspections and checklist verifications performed by site supervisors to identify hazards, ensuring compliance with OSHA standards and company safety policies. Wearable safety technology integrates sensors and real-time monitoring devices that track workers' vital signs and environmental risks, enhancing hazard detection and immediate response. Combining traditional manual protocols with wearable tech optimizes construction site safety management by reducing human error and improving preventive measures.

Overview of Manual Safety Checks

Manual safety checks in construction involve systematic inspections of equipment, tools, and work environments to identify hazards and ensure compliance with safety protocols. These checks rely on trained personnel to visually assess conditions, verify safety measures, and document findings for accountability. Despite being time-consuming, manual inspections remain crucial for detecting immediate risks and reinforcing worker safety awareness on job sites.

Advancements in Wearable Safety Technology

Wearable safety technology in construction has evolved to include real-time hazard detection, biometric monitoring, and location tracking, significantly enhancing worker safety over traditional manual safety checks. These devices use sensors and AI to predict potential accidents before they occur, reducing incident rates and improving emergency response times. Integration of wearable tech with building information modeling (BIM) systems further optimizes site safety management by providing dynamic, data-driven insights.

Key Differences: Manual vs Wearable Safety Systems

Manual safety checks rely on routine inspections and human observation to identify potential hazards, often leading to inconsistencies due to human error and variability. Wearable safety tech integrates real-time monitoring with sensors that track worker vitals, environmental conditions, and fall detection, providing immediate alerts and data-driven insights. The key difference lies in the proactive, continuous data collection of wearables versus the periodic, subjective nature of manual inspections, enhancing overall construction site safety management.

Impact on Incident Reduction and Reporting

Manual safety checks rely heavily on human accuracy and can miss subtle hazards, leading to underreporting of incidents and slower response times. Wearable safety technology, equipped with real-time sensors and automated alerts, significantly enhances incident detection and accelerates reporting, reducing workplace accidents by up to 30%. Integrating wearable devices into construction safety protocols improves hazard identification and data accuracy, driving a measurable decline in on-site injuries.

Cost-Benefit Analysis of Manual and Wearable Solutions

Manual safety checks in construction require significant labor hours and are prone to human error, increasing indirect costs such as downtime and accident-related expenses. Wearable safety technology, including devices like smart helmets and sensor-equipped vests, offers continuous real-time monitoring that reduces incident rates and associated workers' compensation costs. The initial investment in wearable solutions can be offset by long-term savings through enhanced worker productivity, fewer safety violations, and lower insurance premiums.

Worker Training and Compliance Challenges

Manual safety checks rely heavily on worker training and consistent adherence to protocols, often leading to human error and compliance gaps on construction sites. Wearable safety technology offers real-time monitoring and automated alerts, enhancing compliance by reducing the dependency on individual worker vigilance. Integrating wearable devices into safety programs improves training effectiveness and ensures continuous compliance with OSHA regulations.

Data Collection and Real-Time Monitoring Capabilities

Manual safety checks in construction rely on periodic inspections and worker reports, limiting continuous data collection and real-time hazard detection. Wearable safety technology enables constant monitoring of vital signs and environmental conditions, providing instant alerts to prevent accidents. Integration of wearable devices with centralized platforms enhances data accuracy and facilitates proactive safety management on job sites.

Integration with Existing Construction Workflows

Manual safety checks in construction typically rely on scheduled inspections and worker self-reporting, which can disrupt ongoing workflows and lead to delayed hazard identification. Wearable safety technology integrates seamlessly with existing construction workflows by providing real-time monitoring of worker vitals and environmental conditions without interrupting tasks. This integration enhances hazard detection efficiency, promotes proactive safety interventions, and aligns with project timelines through continuous data collection and automated alerts.

Future Trends in Construction Site Safety

Wearable safety technology is rapidly transforming construction site safety by providing real-time biometric monitoring, hazard detection, and location tracking, significantly reducing the reliance on manual safety checks. Future trends emphasize integration of AI-powered wearables that predict risks before incidents occur, enhancing proactive safety management. Adoption of these smart devices promises to improve worker compliance and efficiency, setting new industry standards for accident prevention.

Related Important Terms

Proximity Sensor Alerts

Proximity sensor alerts in wearable safety technology provide real-time hazard detection, significantly reducing the risk of collisions and accidents on construction sites compared to manual safety checks. These devices continuously monitor workers' surroundings, enabling immediate alerts that enhance situational awareness and improve overall site safety standards.

Geofencing for PPE Compliance

Geofencing technology in wearable safety devices enables real-time monitoring of PPE compliance by creating virtual boundaries around hazardous zones, ensuring workers enter these areas only when properly equipped. This automated system reduces reliance on manual safety checks, enhancing site safety through immediate alerts and data-driven enforcement of protective gear protocols.

Real-Time Fatigue Detection

Real-time fatigue detection through wearable safety technology enhances construction site safety by continuously monitoring workers' vital signs such as heart rate variability and movement patterns, enabling immediate alerts when fatigue levels rise. Manual safety checks rely on periodic observations and self-reporting, which can miss subtle or sudden signs of fatigue, limiting proactive intervention and increasing the risk of accidents.

Digital Permit-to-Work (ePTW)

Digital Permit-to-Work (ePTW) systems revolutionize construction safety by automating manual safety checks, reducing human error, and ensuring real-time compliance with safety protocols. Integrating wearable safety technology with ePTW enhances hazard detection and worker monitoring, significantly improving on-site risk management and operational efficiency.

AI-Driven Incident Reporting

AI-driven incident reporting in wearable safety tech dramatically enhances real-time hazard detection and response on construction sites compared to traditional manual safety checks. This technology leverages machine learning algorithms to analyze data from wearables, providing instant alerts and comprehensive incident analytics that improve worker safety and reduce onsite accidents.

Connected Worker Platforms

Connected Worker Platforms integrate wearable safety tech with manual safety checks, enhancing real-time hazard detection and communication on construction sites. These platforms optimize worker safety by leveraging data from wearable devices to automate monitoring processes, reducing human error and increasing compliance with safety protocols.

Haptic Feedback Wearables

Haptic feedback wearables enhance construction site safety by providing real-time tactile alerts for hazards, reducing reliance on manual safety checks prone to human error. These devices improve worker awareness and response times, significantly lowering the risk of accidents in high-risk environments.

Environmental Exposure Monitoring

Manual safety checks rely on periodic inspections that may miss transient hazards, while wearable safety tech continuously monitors environmental exposure such as toxic gases, temperature fluctuations, and noise levels in real time. Integrating wearable sensors improves worker safety by providing immediate alerts and comprehensive data for proactive hazard management on construction sites.

Digital Twins for Safety Audits

Digital twins enhance manual safety checks by creating precise virtual replicas of construction sites for real-time hazard identification and risk assessment. Integrating wearable safety tech with digital twins enables continuous monitoring of worker health and environmental conditions, optimizing safety audits and reducing on-site accidents.

Automated Lone Worker Monitoring

Automated lone worker monitoring systems leverage wearable safety tech equipped with sensors and real-time alerts to enhance hazard detection and worker protection on construction sites, significantly reducing risks compared to manual safety checks. These smart devices enable continuous tracking of workers' location and vital signs, allowing immediate response to emergencies without relying on routine manual inspections.

Manual Safety Checks vs Wearable Safety Tech Infographic

industrydif.com

industrydif.com