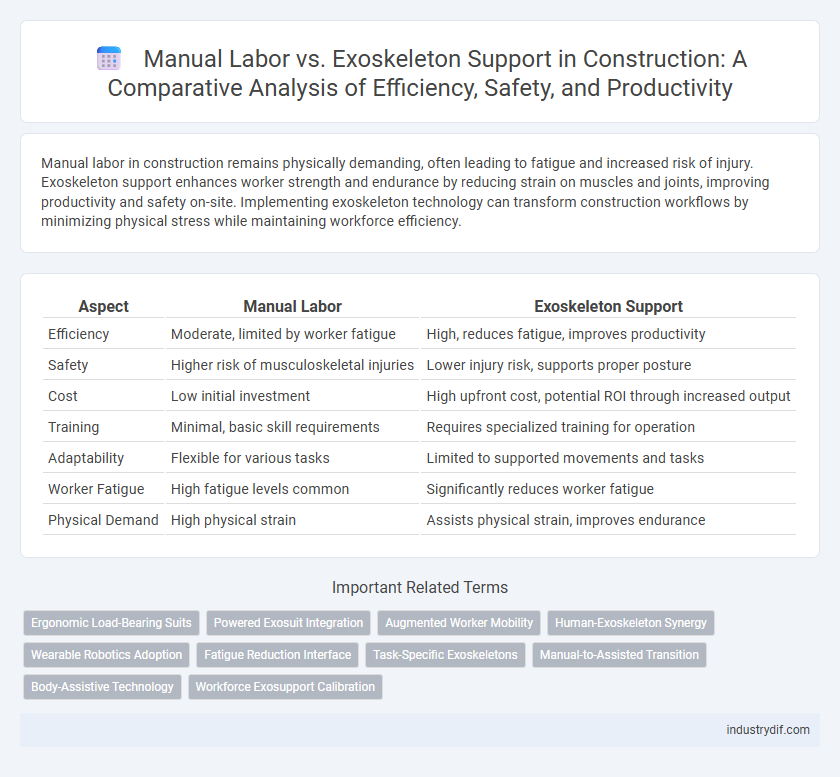

Manual labor in construction remains physically demanding, often leading to fatigue and increased risk of injury. Exoskeleton support enhances worker strength and endurance by reducing strain on muscles and joints, improving productivity and safety on-site. Implementing exoskeleton technology can transform construction workflows by minimizing physical stress while maintaining workforce efficiency.

Table of Comparison

| Aspect | Manual Labor | Exoskeleton Support |

|---|---|---|

| Efficiency | Moderate, limited by worker fatigue | High, reduces fatigue, improves productivity |

| Safety | Higher risk of musculoskeletal injuries | Lower injury risk, supports proper posture |

| Cost | Low initial investment | High upfront cost, potential ROI through increased output |

| Training | Minimal, basic skill requirements | Requires specialized training for operation |

| Adaptability | Flexible for various tasks | Limited to supported movements and tasks |

| Worker Fatigue | High fatigue levels common | Significantly reduces worker fatigue |

| Physical Demand | High physical strain | Assists physical strain, improves endurance |

Introduction to Manual Labor in Construction

Manual labor in construction involves physically demanding tasks such as lifting, carrying, and operating heavy machinery, which are essential for building structures. Workers rely on strength, endurance, and skill to complete activities like masonry, carpentry, and concrete pouring. The reliance on manual labor contributes significantly to project timelines and overall site productivity, but it also increases the risk of fatigue and injury.

Defining Exoskeleton Support Technology

Exoskeleton support technology in construction involves wearable devices designed to augment human strength, reduce fatigue, and enhance safety by redistributing physical load during manual labor tasks. These powered or passive systems integrate mechanical frameworks with sensors and actuators to assist workers in lifting, bending, and repetitive motions, minimizing musculoskeletal injuries. Adoption of exoskeletons improves productivity while complementing, rather than replacing, traditional manual labor by providing ergonomic support on-site.

Historical Perspective: Evolution of Construction Tools

Construction tools have evolved significantly from purely manual labor to advanced exoskeleton support systems, enhancing worker efficiency and safety. Early construction relied heavily on human physical strength with hand tools, while modern innovations integrate powered exoskeletons to reduce fatigue and prevent musculoskeletal injuries. This technological progression marks a pivotal shift in construction ergonomics, optimizing productivity and minimizing occupational hazards.

Key Benefits of Manual Labor Approaches

Manual labor in construction enhances worker dexterity and adaptability, enabling precise handling of diverse materials and tools crucial for complex tasks. It fosters physical fitness and skill development, which contribute to long-term workforce resilience and expertise. Manual techniques also reduce dependency on technology, lowering operational costs and minimizing mechanical failures on site.

Advantages of Exoskeleton Systems for Workers

Exoskeleton systems enhance worker safety by reducing musculoskeletal strain and preventing injuries during heavy lifting and repetitive tasks in construction. These wearable devices improve worker endurance and productivity by distributing loads more efficiently and minimizing fatigue. Implementation of exoskeletons leads to higher job satisfaction and reduced absenteeism due to improved ergonomic support.

Health and Safety Impacts on Construction Crews

Manual labor in construction exposes crews to increased risks of musculoskeletal disorders, fatigue, and workplace injuries due to repetitive heavy lifting and awkward postures. Exoskeleton support reduces physical strain by enhancing strength and endurance, which lowers injury rates and improves overall worker safety. Implementing exoskeleton technology leads to fewer lost workdays and healthier crews, contributing to more sustainable construction site operations.

Productivity Comparisons: Manual vs. Exoskeleton

Manual labor in construction often involves high physical strain and fatigue, limiting overall productivity and increasing downtime. Exoskeleton support enhances worker endurance by reducing musculoskeletal stress, leading to longer work periods and fewer breaks. Studies show that construction crews using exoskeletons can improve productivity by up to 20%, accelerating project timelines and reducing labor costs.

Cost Analysis: Investment and ROI

Manual labor in construction offers low initial investment but tends to incur higher long-term costs due to worker fatigue, injuries, and slower productivity. Exoskeleton support systems require significant upfront capital expenditure, often ranging from $5,000 to $15,000 per unit, but they enhance worker efficiency, reduce injury-related expenses, and improve project timelines, providing a favorable return on investment (ROI) within 1 to 3 years. Cost-benefit analyses reveal that integrating exoskeleton technology can lower operational costs by up to 30%, making it a financially strategic choice for large-scale construction projects.

Training and Workforce Adaptation

Effective training programs for manual laborers transitioning to exoskeleton support emphasize hands-on experience to ensure seamless adaptation and injury prevention. Workforce adaptation requires integrating ergonomic principles with gradual introduction of exoskeleton technology to enhance productivity and reduce physical strain. Continuous skill development and feedback mechanisms are crucial for maximizing the benefits of exoskeletons in construction environments.

Future Trends in Construction Labor Technologies

Future trends in construction labor technologies emphasize the integration of exoskeleton support systems to enhance worker strength and reduce fatigue, leading to higher productivity and fewer injuries. Manual labor remains crucial but is increasingly complemented by wearable robotics that provide ergonomic assistance and improve task efficiency. Advancements in lightweight materials and AI-driven exoskeletons are set to revolutionize labor conditions and skill requirements on construction sites.

Related Important Terms

Ergonomic Load-Bearing Suits

Ergonomic load-bearing suits in construction significantly reduce musculoskeletal strain by redistributing weight and enhancing posture during manual labor, leading to decreased fatigue and injury rates. These exoskeleton supports improve worker efficiency and safety, enabling prolonged physical tasks with reduced ergonomic risk.

Powered Exosuit Integration

Powered exosuit integration in construction sites significantly enhances worker efficiency by augmenting strength and reducing fatigue during manual labor tasks such as lifting heavy materials and repetitive movements. Real-time biomechanics monitoring within these powered exoskeletons improves safety compliance and minimizes injury risks, leading to optimized workforce productivity and lower operational costs.

Augmented Worker Mobility

Exoskeleton support enhances worker mobility on construction sites by reducing physical strain and improving endurance, allowing manual laborers to perform tasks with greater efficiency and less fatigue. This technology integrates biomechanical assistance to augment strength and flexibility, ultimately increasing productivity and minimizing injury risks in demanding environments.

Human-Exoskeleton Synergy

Human-exoskeleton synergy in construction enhances manual labor by reducing physical strain and increasing endurance, enabling workers to perform repetitive and heavy tasks more efficiently. Integration of wearable robotics with human biomechanics optimizes productivity, minimizes injury risks, and supports sustainable workforce performance.

Wearable Robotics Adoption

Wearable robotics, particularly exoskeletons, significantly enhance manual labor efficiency and reduce musculoskeletal injuries on construction sites by supporting heavy lifting and repetitive tasks. Adoption of exoskeleton technology is accelerating as it improves worker endurance, decreases fatigue, and promotes compliance with safety regulations in the construction industry.

Fatigue Reduction Interface

Exoskeleton support systems in construction significantly reduce muscle fatigue by redistributing physical loads and enhancing endurance during repetitive manual labor tasks. Integrating advanced fatigue reduction interfaces with real-time biofeedback sensors optimizes worker performance and minimizes injury risk.

Task-Specific Exoskeletons

Task-specific exoskeletons enhance manual labor efficiency in construction by providing targeted support for repetitive tasks like overhead drilling and heavy lifting, reducing worker fatigue and injury risk. These wearable technologies integrate ergonomic design with advanced materials to optimize force distribution, enabling longer work durations and improved precision on-site.

Manual-to-Assisted Transition

The manual-to-assisted transition in construction significantly enhances worker efficiency by integrating exoskeleton support, reducing physical strain and lowering the risk of musculoskeletal injuries. Implementing exoskeletons accelerates task completion times and improves overall site safety while preserving the essential skills of manual labor through adaptive, hybrid workflows.

Body-Assistive Technology

Body-assistive exoskeletons significantly reduce musculoskeletal strain during construction tasks by providing targeted support to the back, shoulders, and legs, enhancing worker endurance and reducing injury risks compared to traditional manual labor. Integration of wearable exoskeletons in construction sites increases productivity and worker safety by distributing physical loads and enabling prolonged repetitive motion with minimal fatigue.

Workforce Exosupport Calibration

Workforce exosupport calibration enhances manual labor efficiency by optimizing exoskeleton alignment with individual biomechanics, reducing strain and injury risk on construction sites. Precise calibration improves worker endurance and productivity by ensuring ergonomic support tailored to diverse physical demands.

Manual Labor vs Exoskeleton Support Infographic

industrydif.com

industrydif.com