Steel frames offer exceptional strength and durability, making them ideal for high-rise buildings and structures requiring heavy load-bearing capacity. Cross-laminated timber (CLT) provides a sustainable, lightweight alternative with excellent thermal insulation and ease of installation. Comparing steel frame and CLT highlights differences in environmental impact, construction speed, and flexibility in design, guiding material selection based on project priorities.

Table of Comparison

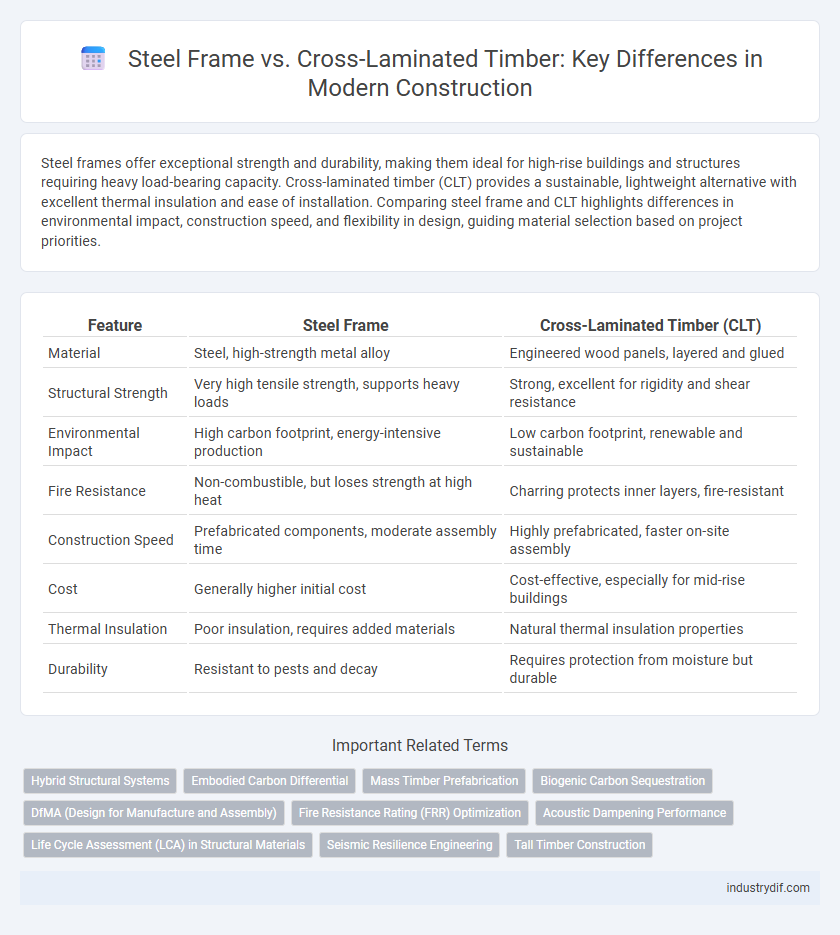

| Feature | Steel Frame | Cross-Laminated Timber (CLT) |

|---|---|---|

| Material | Steel, high-strength metal alloy | Engineered wood panels, layered and glued |

| Structural Strength | Very high tensile strength, supports heavy loads | Strong, excellent for rigidity and shear resistance |

| Environmental Impact | High carbon footprint, energy-intensive production | Low carbon footprint, renewable and sustainable |

| Fire Resistance | Non-combustible, but loses strength at high heat | Charring protects inner layers, fire-resistant |

| Construction Speed | Prefabricated components, moderate assembly time | Highly prefabricated, faster on-site assembly |

| Cost | Generally higher initial cost | Cost-effective, especially for mid-rise buildings |

| Thermal Insulation | Poor insulation, requires added materials | Natural thermal insulation properties |

| Durability | Resistant to pests and decay | Requires protection from moisture but durable |

Introduction to Steel Frame and Cross-Laminated Timber

Steel frame construction utilizes a skeleton of vertical columns and horizontal beams made from high-strength steel, offering superior durability, flexibility, and load-bearing capacity for commercial and industrial buildings. Cross-laminated timber (CLT) consists of layers of solid-sawn lumber glued crosswise, providing excellent structural strength, sustainability, and thermal performance, ideal for mid-rise residential and mixed-use projects. Both materials represent advanced methods in modern construction, with steel known for its robustness and CLT praised for its eco-friendly properties and rapid assembly.

Material Composition and Properties

Steel frame construction utilizes high-strength steel beams and columns known for exceptional tensile strength, durability, and fire resistance, making it ideal for tall structures. Cross-laminated timber (CLT) consists of multiple layers of kiln-dried timber boards stacked perpendicularly and glued, offering high strength-to-weight ratio, natural thermal insulation, and sustainability benefits. While steel provides superior load-bearing capacity and non-combustibility, CLT excels in environmental impact reduction and ease of prefabrication.

Structural Performance Comparison

Steel frames offer superior tensile strength and greater load-bearing capacity, making them ideal for high-rise and heavy-load structures. Cross-laminated timber (CLT) provides excellent seismic performance and superior thermal insulation due to its layered composition and natural flexibility. Both materials demonstrate strong fire resistance when properly treated, but steel's non-combustible nature gives it a distinct advantage in structural durability under extreme conditions.

Sustainability and Environmental Impact

Steel frame construction offers high durability and recyclability but involves significant energy consumption and carbon emissions during production, contributing to a larger environmental footprint. Cross-Laminated Timber (CLT) is a sustainable alternative, sequestering carbon dioxide and using renewable raw materials, resulting in lower embodied energy and reduced greenhouse gas emissions. Studies highlight CLT's potential to decrease construction-related carbon footprints by up to 50% compared to steel framing, making it a preferred choice for eco-conscious building projects.

Cost Analysis and Economic Considerations

Steel frame construction typically involves higher upfront material and labor costs compared to cross-laminated timber (CLT), but offers greater durability and lower long-term maintenance expenses. CLT provides significant savings in construction time and reduced foundation requirements due to its lighter weight, which can translate into lower overall project costs. Economic considerations also include regional availability of materials, with steel often favored in urban or industrial projects, while CLT is increasingly adopted for sustainable, cost-effective residential and mid-rise developments.

Construction Speed and Efficiency

Steel frame construction significantly outpaces cross-laminated timber (CLT) in speed due to prefabricated components that allow rapid on-site assembly and reduce labor time. CLT offers efficiency through large, lightweight panels that enable quick installation and minimize heavy machinery use, particularly beneficial in mid-rise buildings. Both materials enhance construction productivity, but steel frames excel in high-rise projects while CLT is preferred for sustainable, fast-track designs.

Fire Resistance and Safety

Steel frames provide superior fire resistance due to their non-combustible nature, maintaining structural integrity at high temperatures and reducing the need for additional fireproofing treatments. Cross-laminated timber (CLT), while combustible, offers inherent fire resistance through charring, which slows fire spread and maintains load-bearing capacity under specific conditions. Building codes increasingly recognize the fire safety benefits of engineered wood products like CLT, especially when combined with protective finishes and sprinkler systems in modern construction.

Design Flexibility and Architectural Potential

Steel frame construction offers exceptional design flexibility due to its high strength-to-weight ratio, allowing for longer spans, taller buildings, and intricate architectural forms without compromising structural integrity. Cross-laminated timber (CLT) enables innovative, sustainable design with natural aesthetics and excellent thermal performance, promoting biophilic architecture while supporting modular and prefabricated construction methods. Combining steel frames with CLT panels can maximize architectural potential by uniting the durability and versatility of steel with the warmth and sustainability of engineered wood.

Maintenance and Durability

Steel frame structures demonstrate high durability with resistance to pests, fire, and rot, requiring minimal maintenance over time. Cross-laminated timber (CLT) offers excellent structural stability and thermal performance but demands regular inspections and protective treatments to prevent moisture damage and insect infestation. Both materials can achieve long service life; however, steel frames typically present lower maintenance costs and higher resistance to environmental degradation.

Future Trends in Steel and CLT Construction

Future trends in steel frame construction emphasize increased use of lightweight, high-strength alloys and modular prefabrication techniques to enhance speed and sustainability. Cross-laminated timber (CLT) is advancing with innovative treatments to improve fire resistance and durability, promoting its use in taller, more complex structures. Integration of digital design and smart building technologies is accelerating adoption of both steel and CLT, fostering hybrid constructions that optimize structural performance and environmental impact.

Related Important Terms

Hybrid Structural Systems

Hybrid structural systems combine steel frames with cross-laminated timber (CLT) to leverage steel's high tensile strength and CLT's sustainable, lightweight properties, enhancing overall building performance and seismic resilience. These systems optimize load distribution, reduce material costs, and improve construction speed while maintaining fire resistance and acoustic insulation benefits.

Embodied Carbon Differential

Steel frame construction typically results in higher embodied carbon emissions, averaging around 2.1 tons of CO2 per ton of steel, compared to cross-laminated timber (CLT), which can store carbon and often reduces embodied carbon by up to 70%. The use of CLT significantly lowers the carbon footprint of buildings by sequestering carbon throughout the wood's lifecycle, making it a more sustainable choice in terms of embodied carbon impact.

Mass Timber Prefabrication

Mass timber prefabrication, particularly with cross-laminated timber (CLT), offers a sustainable and lightweight alternative to traditional steel frame construction by enabling faster assembly and reducing onsite waste. CLT panels provide superior thermal performance and seismic resilience, enhancing the efficiency and environmental footprint of modern building projects.

Biogenic Carbon Sequestration

Steel frame construction stores minimal biogenic carbon due to its primarily mineral-based composition, resulting in higher embodied carbon emissions. Cross-laminated timber (CLT) acts as a significant carbon sink by sequestering biogenic carbon throughout its lifecycle, reducing the overall carbon footprint of buildings.

DfMA (Design for Manufacture and Assembly)

Steel frame systems enhance DfMA by allowing precise offsite fabrication and rapid onsite assembly, reducing construction time and waste. Cross-laminated timber offers sustainable DfMA benefits with lightweight panels that simplify transportation and installation, but may require additional coordination for structural connections compared to steel.

Fire Resistance Rating (FRR) Optimization

Steel frame structures offer high fire resistance ratings, often achieving up to 4-hour FRR due to non-combustible properties and consistent performance under intense heat. Cross-laminated timber can reach comparable fire resistance levels through char layer formation and increased panel thickness, enabling optimized FRR while maintaining sustainability and thermal insulation benefits.

Acoustic Dampening Performance

Steel frames typically exhibit higher sound transmission due to their rigid structure, requiring additional insulation materials to achieve effective acoustic dampening. Cross-laminated timber (CLT) inherently provides superior acoustic performance through its layered wood panels, which absorb and reduce noise vibration more efficiently in construction applications.

Life Cycle Assessment (LCA) in Structural Materials

Steel frames offer high durability and recyclability, but their production involves significant carbon emissions and energy consumption, impacting the overall life cycle assessment negatively. Cross-laminated timber (CLT) demonstrates a lower carbon footprint due to its renewable sourcing and carbon sequestration during growth, making it a more sustainable choice in structural materials when considering environmental impacts across the entire life cycle.

Seismic Resilience Engineering

Steel frames offer superior seismic resilience engineering due to their high tensile strength and ductility, enabling structures to absorb and dissipate earthquake energy effectively. Cross-laminated timber (CLT) provides competitive seismic performance through its lightweight nature and cross-layered configuration, which enhances flexibility and energy dissipation in seismic events.

Tall Timber Construction

Tall timber construction using cross-laminated timber (CLT) offers enhanced sustainability and faster assembly compared to traditional steel frame structures, significantly reducing carbon emissions and on-site labor costs. While steel frames provide superior strength and flexibility for extremely tall buildings, CLT is increasingly favored in mid-rise developments due to its renewable properties and thermal performance benefits.

Steel Frame vs Cross-Laminated Timber Infographic

industrydif.com

industrydif.com