Manual takeoff involves physically measuring plans and documents to estimate material quantities, relying heavily on human accuracy and time. Digital takeoff uses specialized software to quickly and precisely calculate measurements from digital blueprints, enhancing efficiency and reducing errors. Embracing digital takeoff technology significantly accelerates project estimation while improving accuracy and resource management in construction.

Table of Comparison

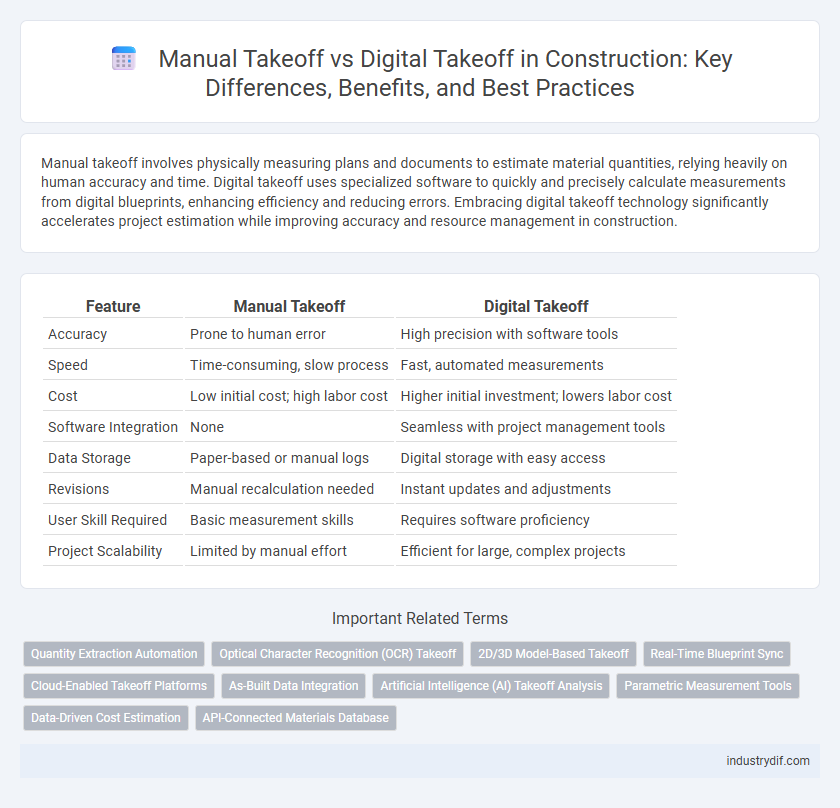

| Feature | Manual Takeoff | Digital Takeoff |

|---|---|---|

| Accuracy | Prone to human error | High precision with software tools |

| Speed | Time-consuming, slow process | Fast, automated measurements |

| Cost | Low initial cost; high labor cost | Higher initial investment; lowers labor cost |

| Software Integration | None | Seamless with project management tools |

| Data Storage | Paper-based or manual logs | Digital storage with easy access |

| Revisions | Manual recalculation needed | Instant updates and adjustments |

| User Skill Required | Basic measurement skills | Requires software proficiency |

| Project Scalability | Limited by manual effort | Efficient for large, complex projects |

Introduction to Takeoff Methods in Construction

Manual takeoff in construction involves physically measuring and quantifying materials from blueprints or drawings, relying on traditional tools like rulers and scales. Digital takeoff utilizes specialized software to extract measurements and material quantities directly from digital plans, enhancing accuracy and efficiency. Both methods serve to estimate project requirements but differ significantly in speed, precision, and integration with other construction management tools.

Defining Manual Takeoff: Process and Tools

Manual takeoff in construction involves the traditional process of measuring and quantifying materials directly from physical blueprints using tools like scales, rulers, and calculators. This labor-intensive method requires detailed examination of paper plans to estimate quantities for labor, materials, and costs. Despite being time-consuming, manual takeoff remains a foundational technique for accurate project scope definition in environments lacking digital resources.

Digital Takeoff Explained: Software and Technology

Digital takeoff utilizes advanced software solutions such as Bluebeam Revu, PlanSwift, and On-Screen Takeoff, which streamline the quantity measurement process with precision and speed. These tools integrate with Building Information Modeling (BIM) and cloud-based platforms to enhance collaboration, reduce errors, and provide real-time data updates. By automating material calculations and generating detailed reports, digital takeoff technology significantly improves cost estimation accuracy and project efficiency in construction management.

Accuracy and Error Rates: Manual vs Digital

Manual takeoff in construction projects often results in higher error rates due to human miscalculations and data entry mistakes, significantly impacting project accuracy. Digital takeoff software leverages advanced algorithms and precise measurements from blueprints or CAD files, drastically reducing errors and improving overall project estimation accuracy. Implementing digital takeoff tools enhances confidence in quantity takeoffs and cost predictions by minimizing discrepancies typically seen in manual methods.

Efficiency and Time Investment Comparison

Manual takeoff requires extensive time and labor as estimators physically measure plans and record quantities, making it prone to human error and inefficiency in large-scale projects. Digital takeoff software automates measurements, significantly reducing time investment by allowing instant quantity calculations and easy modifications, enhancing overall project efficiency. The integration of digital tools streamlines workflows, decreases rework, and accelerates project timelines compared to traditional manual methods.

Cost Implications: Upfront and Long-Term

Manual takeoff requires minimal initial investment but significantly increases labor costs and the risk of errors over time, leading to costly project delays and material wastage. Digital takeoff tools involve higher upfront expenses for software and training but improve accuracy, speed, and productivity, resulting in substantial long-term cost savings. Investing in digital solutions reduces overall project expenses by streamlining workflows and minimizing rework.

Collaboration and Communication Benefits

Digital takeoff enhances collaboration by enabling real-time sharing and updating of project measurements across multiple stakeholders, reducing errors and miscommunication. Cloud-based platforms allow teams to access and edit takeoff data simultaneously, fostering transparent communication and faster decision-making. Manual takeoff often limits collaboration due to static, paper-based documents, causing delays and inconsistencies in project coordination.

Data Management and Storage Solutions

Manual takeoff relies heavily on physical blueprints and manual calculations, which often result in fragmented data management and increased risk of errors in storage. Digital takeoff leverages cloud-based platforms and integrated software solutions that centralize data storage, enabling seamless collaboration and real-time updates across project teams. Efficient data management through digital takeoff enhances accuracy, reduces redundancies, and accelerates decision-making in construction project workflows.

Scalability and Adaptability in Modern Projects

Digital takeoff tools offer superior scalability and adaptability for modern construction projects by enabling quick adjustments to project scope and easy integration with Building Information Modeling (BIM) software. Manual takeoff methods often struggle to keep pace with expanding project complexities and frequent design changes, leading to increased time and potential errors. Embracing digital solutions enhances accuracy, accelerates workflows, and supports evolving project demands in large-scale construction environments.

Future Trends in Construction Takeoff Methods

Future trends in construction takeoff methods emphasize the increasing adoption of digital takeoff tools powered by AI and machine learning algorithms, which enhance accuracy and efficiency compared to manual takeoff processes. Integration of Building Information Modeling (BIM) and cloud-based platforms further streamlines data sharing and real-time collaboration among project stakeholders. Emerging technologies like drone surveying and 3D scanning are also revolutionizing quantity measurement, enabling precise, automated takeoffs that reduce human error and accelerate project timelines.

Related Important Terms

Quantity Extraction Automation

Manual takeoff in construction involves labor-intensive, time-consuming processes prone to human error when extracting quantities from blueprints, whereas digital takeoff utilizes advanced software and automation to rapidly and accurately quantify materials and components. Implementing quantity extraction automation reduces estimation errors, accelerates project timelines, and enhances cost control by integrating with BIM and CAD systems for precise measurements.

Optical Character Recognition (OCR) Takeoff

Optical Character Recognition (OCR) takeoff revolutionizes construction estimating by converting paper blueprints and scanned documents into accurate digital measurements, significantly reducing manual errors and time compared to traditional manual takeoff methods. Integrating OCR technology streamlines quantity extraction, enhances project accuracy, and facilitates seamless data transfer into estimating software, optimizing overall construction workflow efficiency.

2D/3D Model-Based Takeoff

Manual takeoff relies on physical blueprints and hand measurements, which increases the risk of human error and slows project timelines. In contrast, digital takeoff leverages advanced 2D and 3D model-based takeoff software, enabling precise quantity estimations, faster calculations, and seamless integration with BIM systems for enhanced project accuracy and efficiency.

Real-Time Blueprint Sync

Digital takeoff tools enable real-time blueprint sync, allowing construction teams to instantly update measurements and quantities as changes occur, reducing errors and improving project accuracy. Manual takeoff methods lack this instant connectivity, often causing delays and inconsistencies in project planning and cost estimation.

Cloud-Enabled Takeoff Platforms

Cloud-enabled takeoff platforms streamline construction estimating by providing real-time collaboration, automated measurements, and integration with project management tools, significantly reducing manual errors and time consumption associated with traditional manual takeoff methods. These digital solutions leverage cloud computing to offer scalable storage, easy access from multiple devices, and continuous updates, enhancing accuracy and efficiency across all project phases.

As-Built Data Integration

Manual takeoff methods often struggle with integrating as-built data efficiently, leading to increased errors and project delays. Digital takeoff solutions enable seamless incorporation of as-built data into construction plans, enhancing accuracy and streamlining project workflows.

Artificial Intelligence (AI) Takeoff Analysis

AI takeoff analysis enhances accuracy and efficiency by automating quantity measurements and material estimations using machine learning algorithms, reducing human error compared to traditional manual takeoff methods. This digital approach leverages computer vision and data analytics to expedite project timelines and optimize cost control in construction planning.

Parametric Measurement Tools

Parametric measurement tools in digital takeoff enable precise quantification of construction elements by automatically adjusting dimensions based on design parameters, significantly reducing errors compared to manual takeoff methods. The integration of these tools streamlines project estimates and improves accuracy in material and labor cost calculations, driving efficiency in construction planning.

Data-Driven Cost Estimation

Manual takeoff relies on physical blueprints and manual measurement, often resulting in slower, less accurate quantity calculations that can increase cost estimation errors. Digital takeoff utilizes software tools with integrated databases and real-time data analytics to deliver precise material quantities and labor costs, enhancing data-driven cost estimation accuracy and project budgeting efficiency.

API-Connected Materials Database

API-connected materials databases in digital takeoff streamline project workflows by providing real-time access to accurate quantities, specifications, and pricing, reducing errors compared to manual takeoff methods. This integration enables faster updates, improved collaboration, and seamless synchronization with estimating and procurement systems, enhancing overall construction project efficiency.

Manual Takeoff vs Digital Takeoff Infographic

industrydif.com

industrydif.com