Brick-and-mortar construction offers durability and customization through traditional building methods, making it ideal for complex architectural designs. Modular construction accelerates project timelines by assembling prefabricated sections off-site, reducing labor costs and minimizing site disruption. Comparing both approaches highlights trade-offs between flexibility, speed, and cost efficiency for different construction needs.

Table of Comparison

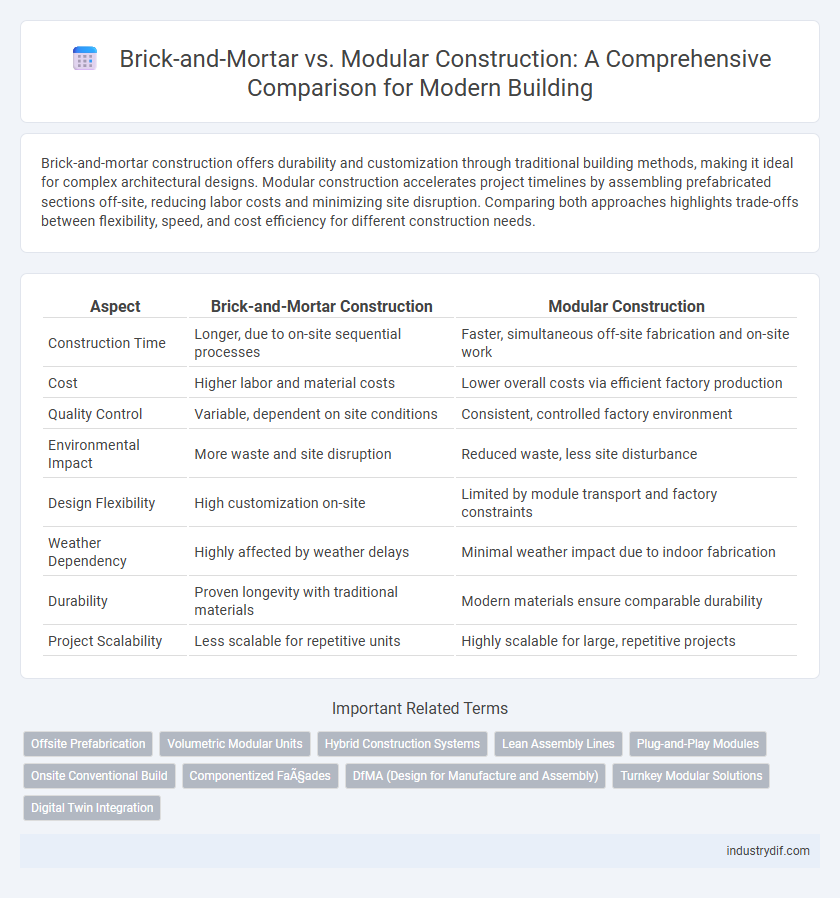

| Aspect | Brick-and-Mortar Construction | Modular Construction |

|---|---|---|

| Construction Time | Longer, due to on-site sequential processes | Faster, simultaneous off-site fabrication and on-site work |

| Cost | Higher labor and material costs | Lower overall costs via efficient factory production |

| Quality Control | Variable, dependent on site conditions | Consistent, controlled factory environment |

| Environmental Impact | More waste and site disruption | Reduced waste, less site disturbance |

| Design Flexibility | High customization on-site | Limited by module transport and factory constraints |

| Weather Dependency | Highly affected by weather delays | Minimal weather impact due to indoor fabrication |

| Durability | Proven longevity with traditional materials | Modern materials ensure comparable durability |

| Project Scalability | Less scalable for repetitive units | Highly scalable for large, repetitive projects |

Introduction to Brick-and-Mortar and Modular Construction

Brick-and-mortar construction involves traditional on-site building methods using materials like bricks, mortar, and concrete, emphasizing structural stability and customized architectural designs. Modular construction assembles prefabricated sections in a factory setting, allowing for faster project completion and consistent quality control. Both methods impact project timelines, cost efficiency, and environmental considerations differently, making them critical choices in modern construction planning.

Defining Key Terms: Traditional vs Modular Methods

Brick-and-mortar construction refers to traditional building methods involving on-site assembly of materials such as bricks, mortar, concrete, and wood, allowing for customization and adaptation during the construction process. Modular construction involves prefabricating sections or modules of a building off-site in a controlled factory environment, which are then transported and assembled on-site, improving time efficiency and reducing waste. Understanding these key terms highlights the differences in processes, timelines, and potential cost implications between traditional and modular construction methods.

Historical Development of Construction Techniques

Brick-and-mortar construction, dating back thousands of years, has been the foundation of traditional building methods with materials like clay bricks and mortar allowing durable and fire-resistant structures. Modular construction emerged in the 20th century, leveraging factory-built, pre-fabricated modules to enhance efficiency, reduce waste, and accelerate project timelines. Advances in materials science and construction technology have driven the evolution from labor-intensive bricklaying to innovative modular systems, reshaping the industry's approach to scalability and cost-effectiveness.

Speed and Efficiency: Comparing Timelines

Modular construction significantly accelerates project timelines by enabling simultaneous off-site fabrication and on-site preparation, reducing overall build time by up to 50% compared to traditional brick-and-mortar methods. Factory-controlled environments enhance quality and minimize weather-related delays, ensuring consistent progress and faster completion. Brick-and-mortar construction, reliant on sequential on-site processes, often faces extended timelines due to labor availability, material delivery, and environmental factors.

Cost Analysis: Upfront and Long-Term Expenses

Brick-and-mortar construction typically incurs higher upfront costs due to labor-intensive processes and material expenses, with long-term maintenance costs influenced by weather-related wear and structural aging. Modular construction offers reduced initial expenses through factory-controlled production and shorter on-site assembly times, leading to lower labor and financing costs. Over time, modular buildings often provide cost savings from enhanced energy efficiency, faster occupancy, and decreased repair needs.

Quality Control and Building Standards

Brick-and-mortar construction involves on-site building processes that rely heavily on manual workmanship, leading to potential variability in quality control and adherence to building standards. Modular construction, by contrast, uses factory-controlled environments that allow for consistent quality assurance and strict compliance with building codes throughout the production cycle. This controlled setting reduces construction defects and enhances overall structural integrity compared to traditional methods.

Flexibility and Customization Options

Brick-and-mortar construction offers extensive flexibility in design customization, allowing for tailored architectural details and unique structural elements suited to specific site conditions. Modular construction provides rapid assembly with standardized components, but customization options are often limited by factory production constraints and transportation sizes. Both methods support diverse material choices, yet traditional builds excel in on-site adaptations, while modular systems optimize efficiency through repeatable design modules.

Environmental Impact and Sustainability

Modular construction significantly reduces waste by up to 90% compared to traditional brick-and-mortar methods, promoting resource efficiency and minimizing landfill contributions. The controlled factory environment allows precise material usage and energy-efficient processes, lowering carbon footprint and greenhouse gas emissions during construction. Moreover, modular buildings often incorporate sustainable materials and enable easier disassembly and recycling, enhancing long-term environmental benefits over conventional construction.

Regulatory and Permitting Challenges

Brick-and-mortar construction faces extensive regulatory scrutiny due to traditional building codes and zoning laws that vary significantly by location, often causing delays in project approvals. Modular construction encounters challenges in meeting these regulations because prefabricated components must comply with both factory standards and onsite building codes, requiring dual inspections and certifications. Navigating these complex permitting processes demands specialized expertise to ensure compliance across jurisdictions, impacting project timelines and costs in both construction methods.

Future Trends in Construction Methods

Modular construction is rapidly advancing with innovations in prefabrication technology and digital integration, enabling faster project completion and reduced labor costs compared to traditional brick-and-mortar methods. Sustainable building practices and increased demand for affordable housing are driving the adoption of modular techniques that minimize waste and enhance energy efficiency. Emerging trends emphasize hybrid models combining physical on-site work with precision off-site fabrication to optimize flexibility and scalability in the construction industry.

Related Important Terms

Offsite Prefabrication

Offsite prefabrication in modular construction accelerates project timelines by manufacturing building components in a controlled factory environment, reducing on-site labor and minimizing weather-related delays. This method enhances quality control, decreases waste, and improves safety compared to traditional brick-and-mortar construction, where building occurs entirely on-site.

Volumetric Modular Units

Volumetric modular units offer significant advantages in construction speed and quality control by assembling fully finished sections offsite before transportation to the site, reducing onsite labor and weather-related delays compared to traditional brick-and-mortar methods. These prefabricated units enable precise factory fabrication, promote sustainability through material efficiency, and support scalable, repeatable building designs ideal for residential and commercial projects.

Hybrid Construction Systems

Hybrid construction systems integrate traditional brick-and-mortar techniques with modular construction methods, enhancing project efficiency and structural versatility. This approach reduces onsite labor and construction time while maintaining the durability and aesthetic appeal of conventional masonry.

Lean Assembly Lines

Modular construction leverages lean assembly lines to enhance efficiency by fabricating components in controlled factory settings, significantly reducing material waste and construction time compared to traditional brick-and-mortar methods. This streamlined approach facilitates precise quality control, minimizes on-site disruptions, and accelerates project delivery, making it a cost-effective alternative in modern building practices.

Plug-and-Play Modules

Plug-and-play modules in modular construction offer rapid assembly and consistent quality control compared to traditional brick-and-mortar methods, significantly reducing project timelines and labor costs. These pre-fabricated units are manufactured in controlled environments, ensuring precise specifications and minimizing on-site disruptions while enhancing scalability and design flexibility.

Onsite Conventional Build

Onsite conventional build in brick-and-mortar construction involves traditional methods where materials like bricks, mortar, and concrete are assembled directly at the construction site, allowing for customization and adaptability to site-specific conditions. This approach often results in longer project timelines and increased labor costs compared to modular construction, but it provides superior structural integrity and design flexibility for complex architectural projects.

Componentized Façades

Componentized facades in modular construction offer precise factory fabrication, reducing on-site labor and enhancing quality control compared to traditional brick-and-mortar methods. These prefabricated facade panels enable faster installation, improved thermal performance, and greater design flexibility while minimizing construction waste and project timelines.

DfMA (Design for Manufacture and Assembly)

DfMA enhances modular construction by streamlining design processes to maximize off-site fabrication and reduce on-site assembly time, resulting in improved efficiency and quality control compared to traditional brick-and-mortar methods. Integrating DfMA principles accelerates project timelines and minimizes waste, making modular construction a cost-effective and sustainable alternative in the building industry.

Turnkey Modular Solutions

Turnkey modular solutions streamline construction by delivering fully finished, inspected, and ready-to-use structures, significantly reducing on-site labor and project timelines compared to traditional brick-and-mortar methods. This approach enhances quality control and cost efficiency through factory precision and standardized processes, making it ideal for fast-track commercial and residential developments.

Digital Twin Integration

Brick-and-mortar construction benefits from digital twin integration by enabling detailed, real-time monitoring of building performance and maintenance needs, improving long-term asset management. Modular construction leverages digital twins to optimize off-site fabrication processes, enhance precision, and reduce construction timelines through virtual prototyping and iterative design adjustments.

Brick-and-Mortar vs Modular Construction Infographic

industrydif.com

industrydif.com