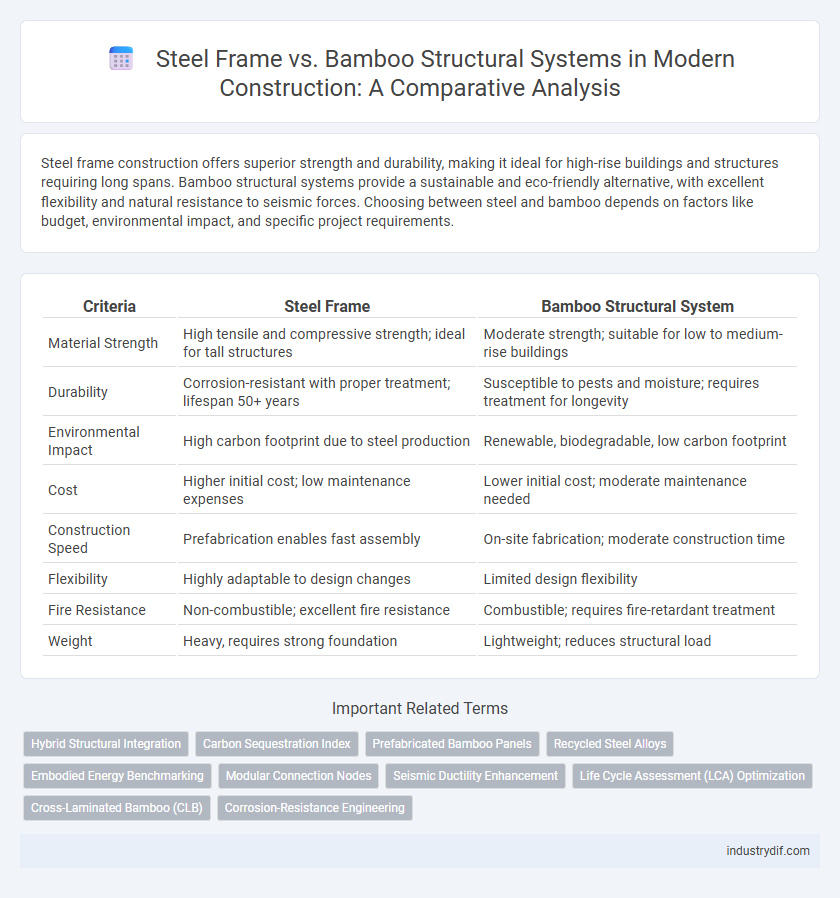

Steel frame construction offers superior strength and durability, making it ideal for high-rise buildings and structures requiring long spans. Bamboo structural systems provide a sustainable and eco-friendly alternative, with excellent flexibility and natural resistance to seismic forces. Choosing between steel and bamboo depends on factors like budget, environmental impact, and specific project requirements.

Table of Comparison

| Criteria | Steel Frame | Bamboo Structural System |

|---|---|---|

| Material Strength | High tensile and compressive strength; ideal for tall structures | Moderate strength; suitable for low to medium-rise buildings |

| Durability | Corrosion-resistant with proper treatment; lifespan 50+ years | Susceptible to pests and moisture; requires treatment for longevity |

| Environmental Impact | High carbon footprint due to steel production | Renewable, biodegradable, low carbon footprint |

| Cost | Higher initial cost; low maintenance expenses | Lower initial cost; moderate maintenance needed |

| Construction Speed | Prefabrication enables fast assembly | On-site fabrication; moderate construction time |

| Flexibility | Highly adaptable to design changes | Limited design flexibility |

| Fire Resistance | Non-combustible; excellent fire resistance | Combustible; requires fire-retardant treatment |

| Weight | Heavy, requires strong foundation | Lightweight; reduces structural load |

Introduction to Steel and Bamboo Structural Systems

Steel frame structural systems offer high strength-to-weight ratios, durability, and resistance to environmental factors, making them ideal for high-rise buildings and industrial construction. Bamboo structural systems provide sustainable, flexible, and lightweight alternatives with natural tensile strength, extensively used in eco-friendly and low-cost housing projects. Both systems require specialized design considerations to optimize load distribution, seismic performance, and long-term durability in varying construction contexts.

Material Properties: Steel vs Bamboo

Steel offers superior tensile strength, durability, and resistance to pests and fire, making it a reliable choice for high-load structural applications. Bamboo provides exceptional flexibility, lightweight characteristics, and rapid renewability, promoting sustainable construction with lower environmental impact. Combining these materials can optimize structural performance by leveraging steel's robustness and bamboo's eco-friendly properties.

Sustainability and Environmental Impact

Steel frames offer high durability and strength but involve significant carbon emissions during manufacturing, impacting environmental sustainability negatively. Bamboo structural systems provide a renewable, low-carbon alternative with rapid growth rates that contribute to carbon sequestration and reduced ecological footprint. The choice between steel and bamboo frames significantly affects the construction industry's sustainability goals, favoring bamboo for eco-friendly, resource-efficient buildings.

Cost Comparison: Steel Frame vs Bamboo

The cost comparison between steel frame and bamboo structural systems reveals significant differences driven by material prices and labor requirements. Steel frames typically incur higher initial costs due to steel's industrial processing and transportation expenses, while bamboo offers a more affordable alternative with low material and local labor costs, especially in regions where bamboo is abundant. However, maintenance and durability factors may influence the overall lifecycle cost, with steel frames generally providing longer-term resilience compared to bamboo.

Structural Strength and Durability

Steel frame structures exhibit superior structural strength due to their high tensile and compressive resistance, making them ideal for high-rise buildings and heavy load conditions. Bamboo structural systems offer excellent flexibility and resilience against seismic forces, but typically possess lower durability, requiring treatment against pests and moisture to enhance lifespan. Steel's corrosion resistance and uniformity ensure long-term durability, while bamboo is favored for sustainable construction despite its need for regular maintenance.

Construction Speed and Ease of Installation

Steel frame construction offers rapid assembly due to prefabricated components and uniform material properties that facilitate precise, quick installations. Bamboo structural systems, while eco-friendly and lightweight, often require skilled craftsmanship and additional time for joint treatments, slowing overall construction speed. Both systems benefit from modular approaches, but steel frames typically outperform bamboo in ease of installation on large-scale projects.

Maintenance Requirements

Steel frame structures require periodic inspections for corrosion, especially in humid or coastal environments, and necessitate protective coatings or galvanization to prevent rust. Bamboo structural systems demand regular treatment against pests such as termites and fungi, including applications of preservatives and moisture control measures to maintain durability. Maintenance costs for steel may be higher initially, but bamboo requires more frequent upkeep to ensure longevity in varying climatic conditions.

Fire and Pest Resistance

Steel frame structures offer superior fire resistance due to their non-combustible nature and high melting point, significantly reducing fire-related risks in construction. In contrast, bamboo structural systems are vulnerable to fire damage but can be treated with fire-retardant chemicals to improve resistance. Pest resistance in steel frames is inherently strong, preventing termite and insect infestations that commonly affect untreated bamboo, which requires regular treatment to maintain durability against pests.

Applications in Modern Construction

Steel frame structural systems offer superior strength, durability, and fire resistance, making them ideal for high-rise buildings, commercial complexes, and industrial facilities where load-bearing capacity and longevity are critical. Bamboo structural systems provide sustainable, lightweight, and flexible alternatives, especially suitable for residential housing, eco-friendly resorts, and low-rise structures in seismic zones due to bamboo's natural shock-absorption properties. Modern construction increasingly integrates bamboo for green building certifications and steel frames for enabling architectural innovation and maximized structural performance.

Future Trends in Structural System Selection

Steel frames dominate modern construction due to superior strength, durability, and adaptability in high-rise buildings, while bamboo structural systems gain traction for sustainable, low-cost, and eco-friendly applications in residential and rural projects. Innovations in composite materials and hybrid designs integrating steel and bamboo enhance performance, promoting environmental benefits without compromising structural integrity. Future trends emphasize lifecycle carbon footprint reduction, regulatory incentives for green materials, and advancements in prefabrication technologies to optimize both steel and bamboo structural systems.

Related Important Terms

Hybrid Structural Integration

Hybrid structural integration combines steel frame and bamboo systems to maximize strength, flexibility, and sustainability in construction projects. Utilizing steel's high tensile strength alongside bamboo's lightweight, renewable properties enhances load-bearing capacity and environmental performance.

Carbon Sequestration Index

Steel frame construction exhibits a lower Carbon Sequestration Index due to its high embodied energy and limited capacity to absorb CO2 after production. Bamboo structural systems demonstrate a significantly higher Carbon Sequestration Index, as bamboo rapidly absorbs carbon dioxide during growth and stores it effectively within its fibers, making it a more sustainable option for reducing carbon footprints in construction.

Prefabricated Bamboo Panels

Prefabricated bamboo panels offer a sustainable alternative to steel frames in construction by providing high tensile strength, lightweight properties, and rapid assembly, reducing both labor costs and environmental impact. These panels enhance seismic resistance and thermal insulation while promoting renewable resource use, making them ideal for eco-friendly building projects.

Recycled Steel Alloys

Recycled steel alloys in steel frame construction offer superior durability, high strength-to-weight ratio, and excellent resistance to pests and fire compared to bamboo structural systems. The use of recycled steel reduces environmental impact by minimizing raw material extraction and energy consumption, making it an eco-friendly choice for sustainable building projects.

Embodied Energy Benchmarking

Steel frame construction typically exhibits a higher embodied energy ranging from 20 to 50 MJ/kg due to intensive manufacturing and processing, whereas bamboo structural systems show significantly lower embodied energy around 2 to 9 MJ/kg, reflecting their rapid renewability and minimal processing requirements. Benchmarking embodied energy underscores bamboo as a sustainable alternative with reduced carbon footprint in construction, promoting eco-friendly building practices.

Modular Connection Nodes

Modular connection nodes in steel frame systems offer high precision, durability, and ease of assembly due to standardized steel components engineered for load-bearing efficiency and seismic resistance. In contrast, bamboo structural systems rely on handcrafted, flexible nodes that enhance sustainable construction and natural resilience but may face limitations in uniformity and long-term load-bearing capacity.

Seismic Ductility Enhancement

Steel frame structural systems exhibit superior seismic ductility due to their high strength-to-weight ratio and ability to undergo significant plastic deformation without failure. Bamboo structural systems, while sustainable and lightweight, require advanced treatment and design modifications to enhance joint flexibility and energy dissipation for improved seismic performance.

Life Cycle Assessment (LCA) Optimization

Steel frame structures exhibit higher embodied energy and carbon emissions during production compared to bamboo, yet offer superior durability and recyclability, enhancing overall life cycle performance. Bamboo's rapid renewability and lower environmental footprint reduce initial LCA impacts, but its susceptibility to degradation may increase maintenance needs and shorten service life, influencing total life cycle sustainability.

Cross-Laminated Bamboo (CLB)

Cross-Laminated Bamboo (CLB) offers a sustainable alternative to traditional steel frame systems by providing high strength-to-weight ratio, excellent seismic performance, and rapid construction capabilities. Its eco-friendly properties, carbon sequestration benefits, and ability to be prefabricated make CLB an efficient choice for resilient, lightweight structural frameworks in modern construction projects.

Corrosion-Resistance Engineering

Steel frame structural systems offer high corrosion resistance through coatings like galvanization and specialized paint applications, ensuring longevity in harsh environments. Bamboo structural systems rely on natural treatments and protective coatings to enhance durability, but their corrosion resistance is generally lower compared to steel, requiring more frequent maintenance in humid or rainy conditions.

Steel Frame vs Bamboo Structural System Infographic

industrydif.com

industrydif.com