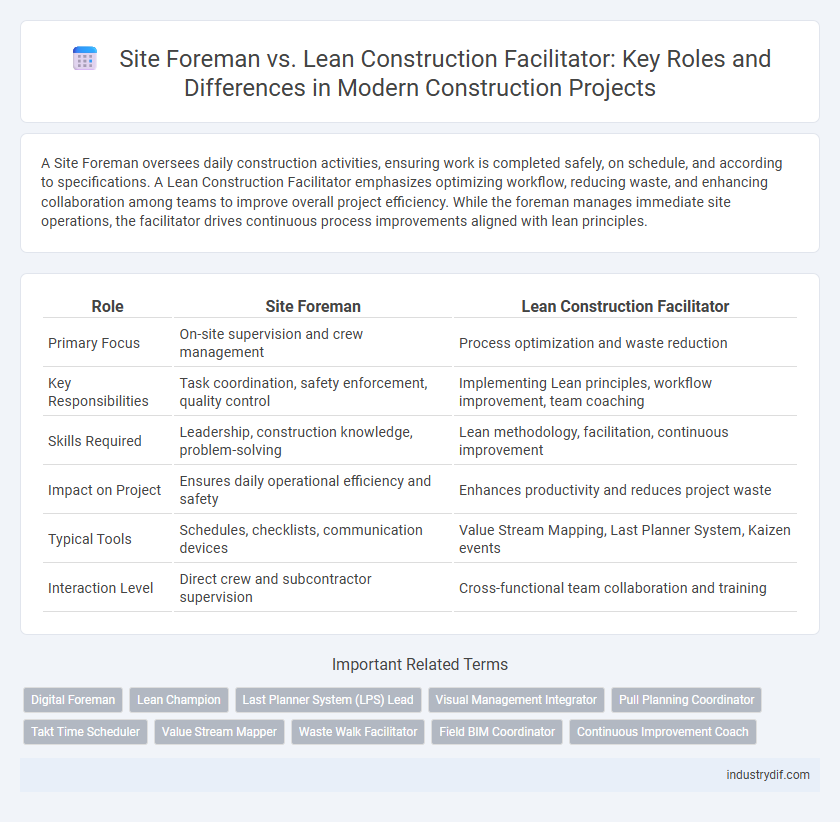

A Site Foreman oversees daily construction activities, ensuring work is completed safely, on schedule, and according to specifications. A Lean Construction Facilitator emphasizes optimizing workflow, reducing waste, and enhancing collaboration among teams to improve overall project efficiency. While the foreman manages immediate site operations, the facilitator drives continuous process improvements aligned with lean principles.

Table of Comparison

| Role | Site Foreman | Lean Construction Facilitator |

|---|---|---|

| Primary Focus | On-site supervision and crew management | Process optimization and waste reduction |

| Key Responsibilities | Task coordination, safety enforcement, quality control | Implementing Lean principles, workflow improvement, team coaching |

| Skills Required | Leadership, construction knowledge, problem-solving | Lean methodology, facilitation, continuous improvement |

| Impact on Project | Ensures daily operational efficiency and safety | Enhances productivity and reduces project waste |

| Typical Tools | Schedules, checklists, communication devices | Value Stream Mapping, Last Planner System, Kaizen events |

| Interaction Level | Direct crew and subcontractor supervision | Cross-functional team collaboration and training |

Role Definition: Site Foreman vs Lean Construction Facilitator

The Site Foreman supervises daily construction activities, manages workforce coordination, and ensures compliance with safety protocols on-site. The Lean Construction Facilitator focuses on optimizing workflows, minimizing waste, and implementing lean methodologies to improve project efficiency and deliver value. While the Site Foreman executes and controls field operations, the Lean Construction Facilitator drives continuous improvement and strategic process enhancements across construction phases.

Core Responsibilities and Daily Tasks

Site Foremen manage on-site operations, ensuring labor coordination, material delivery, and adherence to safety protocols. Lean Construction Facilitators analyze workflow processes, implement lean methodologies to reduce waste, and foster continuous improvement among teams. Both roles require strong communication, but Site Foremen focus on execution, while Lean Facilitators emphasize process optimization and efficiency.

Hierarchical Position in Construction Projects

The Site Foreman commonly holds a mid-level supervisory role, directly managing on-site labor and ensuring daily construction activities align with project plans. In contrast, the Lean Construction Facilitator occupies a more strategic position, often reporting to project managers or executives, focusing on process optimization and waste reduction across various teams. Hierarchically, the Site Foreman operates within operational management, while the Lean Construction Facilitator bridges frontline execution and upper management to enhance overall project efficiency.

Required Skills and Professional Qualifications

A Site Foreman requires strong leadership, construction expertise, technical knowledge, and effective communication skills, often supported by certifications such as OSHA safety training or a construction management diploma. A Lean Construction Facilitator must possess in-depth knowledge of Lean principles, process improvement capabilities, and collaborative problem-solving skills, typically backed by qualifications like Lean Six Sigma certification or specialized training in Lean Construction methodologies. Both roles demand project management experience, but the Foreman focuses on on-site coordination while the Facilitator emphasizes workflow optimization and waste reduction.

Communication and Leadership Styles

A Site Foreman emphasizes direct, task-oriented communication to coordinate daily construction activities, ensuring that teams follow established procedures and safety standards. In contrast, a Lean Construction Facilitator employs collaborative communication and participative leadership, fostering continuous improvement and waste reduction through team engagement and problem-solving. The Foreman's authoritative style centers on control and immediate oversight, while the Lean Facilitator promotes adaptability and shared responsibility for project outcomes.

Workflow Management Approaches

The Site Foreman manages workflow by directly supervising daily on-site activities, ensuring tasks adhere to construction schedules and safety protocols through hands-on coordination. In contrast, the Lean Construction Facilitator employs workflow management approaches centered on optimizing value and minimizing waste by using lean principles such as Last Planner System and continuous improvement cycles. Workflow management in lean construction prioritizes collaborative planning, real-time problem-solving, and streamlined processes to enhance productivity and reduce delays compared to traditional site supervision methods.

Collaboration with Stakeholders

The Site Foreman ensures seamless collaboration with subcontractors, suppliers, and on-site teams to maintain schedule adherence and quality standards. The Lean Construction Facilitator engages stakeholders through continuous improvement workshops and transparent communication channels, promoting waste reduction and process optimization. Both roles coordinate closely to align project goals, enhance productivity, and foster a culture of teamwork across all construction phases.

Impact on Project Efficiency and Productivity

Site Foremen directly manage on-site activities, ensuring materials and labor are effectively coordinated to maintain construction schedules, thus impacting project efficiency through real-time problem-solving and resource allocation. Lean Construction Facilitators employ lean principles to identify and eliminate waste in processes, enhancing productivity by streamlining workflows, reducing delays, and fostering continuous improvement throughout the project lifecycle. Both roles are critical; the Site Foreman drives immediate operational efficiency, while the Lean Construction Facilitator supports long-term productivity gains by optimizing construction processes at a systemic level.

Adaptation to Technological Advancements

Site Foremen primarily manage on-site labor and operations, relying on traditional construction methods and direct supervision to ensure project progress. Lean Construction Facilitators integrate advanced technologies such as Building Information Modeling (BIM) and digital collaboration tools to streamline workflows and reduce waste. Adoption of these technologies enables Lean Construction Facilitators to drive continuous improvement and adaptability in rapidly evolving construction environments.

Career Progression and Industry Demand

Site Foremen typically progress to project manager roles by leveraging hands-on site experience and crew management skills, with steady demand in traditional construction projects. Lean Construction Facilitators focus on optimizing workflows and reducing waste, aligning with industry trends towards efficiency and sustainable practices, resulting in rising demand and faster career growth in innovative construction firms. Career progression for Lean Facilitators is accelerated by proficiency in Lean principles and project integration, positioning them for leadership in modern, technology-driven construction environments.

Related Important Terms

Digital Foreman

The Site Foreman oversees on-site construction activities, ensuring timely progress and safety compliance, while the Lean Construction Facilitator drives process efficiency using lean principles and digital tools. The Digital Foreman integrates real-time data, IoT, and AI technologies to optimize resource allocation, reduce delays, and enhance decision-making on construction sites.

Lean Champion

A Lean Construction Facilitator, often regarded as the Lean Champion, drives continuous improvement by implementing lean principles to eliminate waste, enhance workflow efficiency, and foster collaboration on-site. Unlike a Site Foreman who manages daily operations and labor, the Lean Champion strategically guides teams toward sustainable productivity and value maximization through lean methodologies.

Last Planner System (LPS) Lead

A Site Foreman oversees on-site activities ensuring task completion and safety compliance, while a Lean Construction Facilitator leads the Last Planner System (LPS) by coordinating collaborative planning, optimizing workflow, and improving project reliability. The LPS Lead focuses on removing constraints, enhancing team communication, and driving continuous improvement to reduce waste and increase productivity in construction projects.

Visual Management Integrator

A Site Foreman oversees daily construction activities, ensuring tasks align with project schedules while managing on-site labor and resources. In contrast, a Lean Construction Facilitator acts as a Visual Management Integrator, implementing visual tools and workflows that optimize process transparency, improve team communication, and eliminate waste on the construction site.

Pull Planning Coordinator

The Site Foreman manages daily onsite operations, ensuring tasks are completed according to schedule and safety standards, while the Lean Construction Facilitator specializes in optimizing workflows through pull planning techniques to enhance project efficiency. The Pull Planning Coordinator, typically a role within lean construction, orchestrates collaborative scheduling sessions that align trade contractors' tasks, improving coordination and minimizing delays on construction projects.

Takt Time Scheduler

The Site Foreman manages daily operations and workforce on construction sites, ensuring project milestones meet safety and quality standards. The Lean Construction Facilitator specializes in optimizing workflow using Takt Time scheduling to synchronize tasks, minimize waste, and enhance productivity across the project lifecycle.

Value Stream Mapper

A Site Foreman manages daily construction operations ensuring task execution aligns with project schedules, while a Lean Construction Facilitator employs Value Stream Mapping to identify and eliminate waste across workflows for optimized efficiency. Value Stream Mappers analyze processes from materials delivery to installation, enhancing collaboration and reducing cycle times on construction sites.

Waste Walk Facilitator

A Site Foreman manages on-site labor and daily operations, ensuring task completion and safety compliance, while a Lean Construction Facilitator leads continuous improvement initiatives by identifying inefficiencies through Waste Walks, systematically eliminating waste to enhance project value and reduce costs. The Waste Walk Facilitator role is crucial in applying lean principles to construction site processes, fostering collaboration among teams to streamline workflows and improve resource utilization.

Field BIM Coordinator

The Site Foreman oversees daily construction activities, ensuring safety compliance and workforce coordination, while the Lean Construction Facilitator drives process efficiency through waste reduction and continuous improvement methodologies. The Field BIM Coordinator integrates Building Information Modeling on-site, enhancing real-time collaboration, clash detection, and project scheduling accuracy.

Continuous Improvement Coach

A Site Foreman manages daily construction activities, ensuring project timelines and safety compliance, while a Lean Construction Facilitator acts as a Continuous Improvement Coach, driving workflow optimization and waste reduction through Lean principles. The Lean Construction Facilitator emphasizes collaborative problem-solving and value stream mapping to enhance productivity and project outcomes.

Site Foreman vs Lean Construction Facilitator Infographic

industrydif.com

industrydif.com