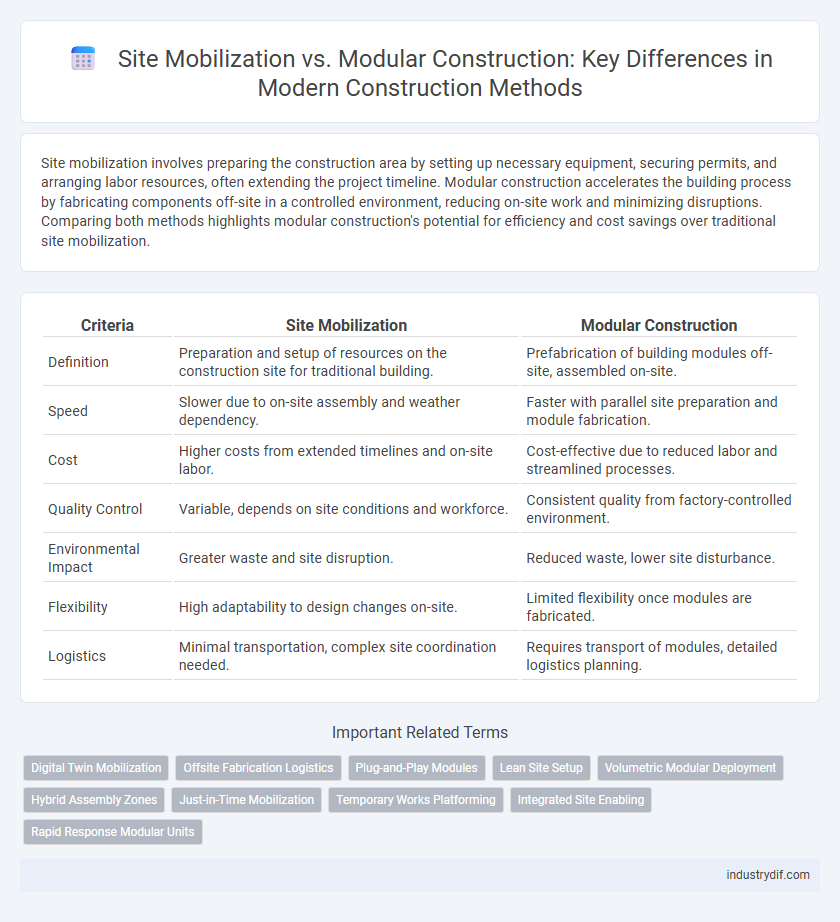

Site mobilization involves preparing the construction area by setting up necessary equipment, securing permits, and arranging labor resources, often extending the project timeline. Modular construction accelerates the building process by fabricating components off-site in a controlled environment, reducing on-site work and minimizing disruptions. Comparing both methods highlights modular construction's potential for efficiency and cost savings over traditional site mobilization.

Table of Comparison

| Criteria | Site Mobilization | Modular Construction |

|---|---|---|

| Definition | Preparation and setup of resources on the construction site for traditional building. | Prefabrication of building modules off-site, assembled on-site. |

| Speed | Slower due to on-site assembly and weather dependency. | Faster with parallel site preparation and module fabrication. |

| Cost | Higher costs from extended timelines and on-site labor. | Cost-effective due to reduced labor and streamlined processes. |

| Quality Control | Variable, depends on site conditions and workforce. | Consistent quality from factory-controlled environment. |

| Environmental Impact | Greater waste and site disruption. | Reduced waste, lower site disturbance. |

| Flexibility | High adaptability to design changes on-site. | Limited flexibility once modules are fabricated. |

| Logistics | Minimal transportation, complex site coordination needed. | Requires transport of modules, detailed logistics planning. |

Introduction to Site Mobilization and Modular Construction

Site mobilization involves the preparation and organization of a construction site, including equipment setup, workforce deployment, and logistics coordination to ensure efficient project commencement. Modular construction consists of manufacturing building components off-site in controlled factory environments, followed by transportation and assembly at the construction site, significantly reducing on-site labor and construction time. Understanding the distinctions between site mobilization and modular construction enhances project planning, resource allocation, and timeline management in the construction industry.

Defining Site Mobilization in Construction Projects

Site mobilization in construction projects involves preparing the construction site for active work, including moving equipment, materials, and personnel to the location. This phase ensures that necessary infrastructure such as temporary offices, utilities, and safety measures are established before construction begins. Effective site mobilization minimizes delays and optimizes workflow, contrasting with modular construction which focuses on off-site prefabrication and assembly.

What is Modular Construction?

Modular construction is a process where buildings are fabricated off-site in controlled factory environments using precise manufacturing techniques. This method allows for faster project completion, higher quality control, and reduced on-site labor compared to traditional site mobilization. Prefabricated modules are transported to the construction site for assembly, minimizing disruptions and enhancing overall efficiency.

Key Differences Between Site Mobilization and Modular Construction

Site mobilization involves preparing and organizing a construction site by transporting equipment, materials, and workforce to enable on-site building activities. Modular construction, in contrast, refers to the off-site fabrication of building components in a controlled factory environment, which are then transported and assembled on location. Key differences include site mobilization's emphasis on logistical setup and groundwork, while modular construction prioritizes efficiency and quality control through pre-fabrication.

Advantages of Site Mobilization Methods

Site mobilization methods offer increased flexibility in adapting to unexpected site conditions, enabling real-time modifications and reducing delays. This approach allows for the use of a diverse range of equipment and skilled labor directly on-site, enhancing customization and quality control. Consequently, site mobilization supports complex projects requiring precise integration with existing structures or challenging terrains.

Benefits of Modular Construction Techniques

Modular construction techniques significantly reduce onsite labor time by fabricating building components offsite in controlled environments, leading to faster project completion and minimized weather-related delays. This method enhances quality control through standardized processes and reduces material waste, promoting sustainability and cost efficiency. Furthermore, modular construction improves safety by limiting onsite hazards and streamlines logistics by consolidating deliveries and workforce management.

Challenges in Site Mobilization

Site mobilization faces significant challenges including logistical complexities, tight schedules, and the need for extensive coordination of labor, equipment, and materials on-site. Weather conditions and site accessibility further complicate timely setup and resource allocation, often leading to project delays. Managing on-site safety protocols while maintaining productivity is critical yet difficult during the initial mobilization phase.

Obstacles in Implementing Modular Construction

Implementing modular construction faces obstacles such as high initial capital investment and supply chain complexities that challenge timely delivery of prefabricated components. Limited availability of skilled labor trained in modular techniques and resistance from traditional construction stakeholders further slow adoption. Regulatory hurdles and zoning restrictions often delay permitting processes, impeding efficient site mobilization for modular projects.

Cost Implications: Site Mobilization vs Modular Construction

Site mobilization incurs high costs due to equipment transport, labor setup, and temporary facilities on location, often leading to extended project timelines and increased labor expenses. Modular construction reduces overall costs by fabricating building components off-site in controlled environments, minimizing material waste and on-site labor hours. Cost savings in modular construction stem from faster project completion, decreased site disruption, and lower risk of weather-related delays.

Future Trends in Construction: Traditional vs Modular Approaches

Site mobilization remains vital for traditional construction projects, involving extensive planning, equipment setup, and workforce coordination on-site. Modular construction is gaining traction due to faster assembly, reduced waste, and improved safety by prefabricating components off-site in controlled environments. Future trends indicate a hybrid approach combining site mobilization precision with modular efficiency will dominate, driven by advancements in automation, digital twins, and sustainable building materials.

Related Important Terms

Digital Twin Mobilization

Digital Twin Mobilization enhances site mobilization by creating an exact virtual replica of the construction site, allowing real-time monitoring and optimization of resources, workflows, and logistics. This digital integration streamlines modular construction processes, reducing delays and improving collaboration between off-site fabrication and on-site assembly.

Offsite Fabrication Logistics

Offsite fabrication logistics in site mobilization involve transporting raw materials and heavy equipment to the construction site, requiring extensive coordination and on-site assembly, whereas modular construction centralizes manufacturing in controlled environments, allowing for precise quality control and reduced on-site labor. Efficient management of offsite fabrication logistics minimizes project delays and site congestion, optimizing the supply chain from factory to installation.

Plug-and-Play Modules

Plug-and-play modules in modular construction significantly reduce site mobilization time by allowing prefabricated units to be quickly assembled on location, minimizing labor and equipment needs. This method enhances project efficiency and cost-effectiveness by streamlining logistics and reducing on-site construction complexities.

Lean Site Setup

Lean site setup in construction emphasizes efficient resource allocation and minimized waste, making site mobilization critical for preparing the groundwork and logistics. Modular construction enhances this process by delivering pre-fabricated components, reducing on-site assembly time and enabling faster project completion with fewer disruptions.

Volumetric Modular Deployment

Volumetric modular deployment accelerates site mobilization by delivering pre-fabricated, fully assembled units directly to the construction site, minimizing on-site labor and reducing project timelines. This method enhances quality control and site safety compared to traditional construction mobilization, enabling faster integration and scalable expansion.

Hybrid Assembly Zones

Hybrid assembly zones blend site mobilization and modular construction, optimizing logistics by preassembling modules off-site while enabling final adjustments on-site. This method reduces on-site labor demand, accelerates project timelines, and enhances quality control through controlled off-site manufacturing environments.

Just-in-Time Mobilization

Site mobilization involves organizing equipment, materials, and labor on location just before construction begins to ensure efficient workflow, while modular construction emphasizes fabricating components off-site in controlled environments for quicker assembly. Just-in-time mobilization minimizes on-site inventory, reduces delays, and optimizes resource allocation by synchronizing deliveries with the construction schedule, enhancing overall project efficiency.

Temporary Works Platforming

Site mobilization involves setting up temporary works and platforming directly on the construction site, enabling tailored adjustments to uneven terrain and specific project requirements. In contrast, modular construction utilizes prefabricated, standardized platforms that reduce on-site assembly time but may require additional support structures for uneven or challenging site conditions.

Integrated Site Enabling

Site mobilization involves preparing and equipping a construction site with necessary resources, machinery, and labor to initiate traditional building processes, emphasizing onsite coordination and logistics management. Modular construction streamlines integrated site enabling by fabricating pre-assembled building components offsite, significantly reducing setup time, minimizing onsite disruptions, and enhancing project efficiency.

Rapid Response Modular Units

Rapid response modular units dramatically reduce site mobilization time by enabling prefabricated components to be quickly transported and assembled onsite, minimizing delays commonly associated with traditional construction methods. This approach enhances project efficiency and accelerates deployment in urgent construction scenarios such as disaster relief or temporary facilities.

Site Mobilization vs Modular Construction Infographic

industrydif.com

industrydif.com