Site surveys provide real-time, on-ground data critical for accurate measurements and immediate issue identification, while digital twin assessments utilize virtual models to simulate, analyze, and optimize construction processes remotely. Digital twins enable continuous monitoring and predictive maintenance by integrating IoT sensors and data analytics, enhancing decision-making without physical presence. Combining both methods ensures comprehensive project insights, improving accuracy, efficiency, and risk management across construction phases.

Table of Comparison

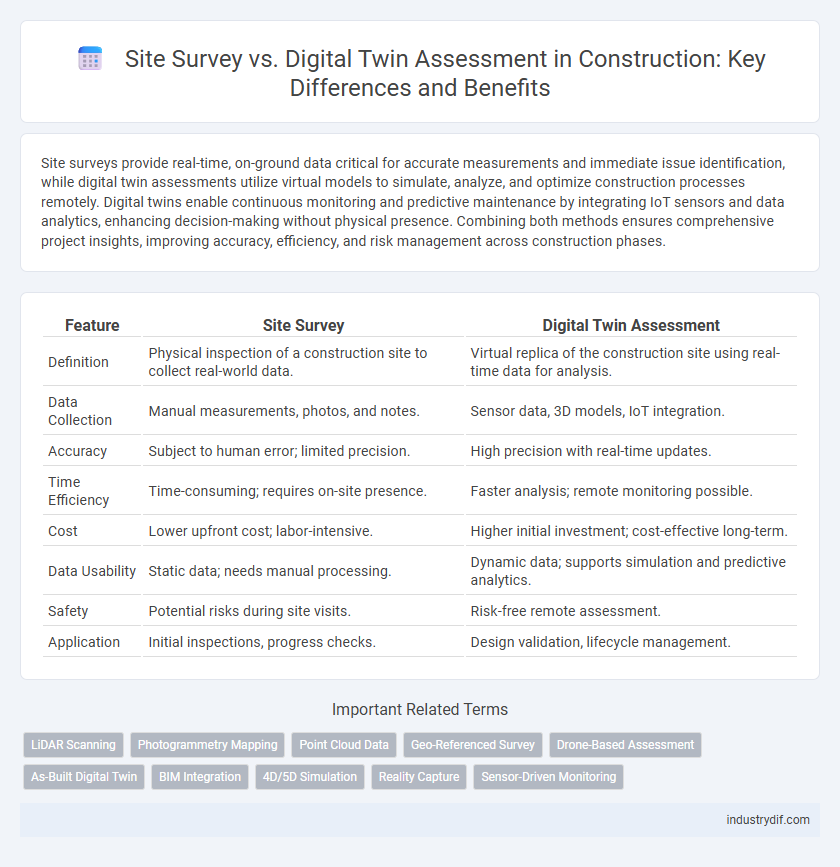

| Feature | Site Survey | Digital Twin Assessment |

|---|---|---|

| Definition | Physical inspection of a construction site to collect real-world data. | Virtual replica of the construction site using real-time data for analysis. |

| Data Collection | Manual measurements, photos, and notes. | Sensor data, 3D models, IoT integration. |

| Accuracy | Subject to human error; limited precision. | High precision with real-time updates. |

| Time Efficiency | Time-consuming; requires on-site presence. | Faster analysis; remote monitoring possible. |

| Cost | Lower upfront cost; labor-intensive. | Higher initial investment; cost-effective long-term. |

| Data Usability | Static data; needs manual processing. | Dynamic data; supports simulation and predictive analytics. |

| Safety | Potential risks during site visits. | Risk-free remote assessment. |

| Application | Initial inspections, progress checks. | Design validation, lifecycle management. |

Introduction to Site Survey and Digital Twin Assessment

Site survey involves on-site data collection and analysis to evaluate construction conditions, measurements, and environmental factors critical for project planning and execution. Digital Twin assessment leverages virtual replicas of physical sites created through sensors, 3D modeling, and real-time data integration to enhance visualization, monitoring, and predictive analysis. Combining traditional site surveys with Digital Twin technology improves accuracy, decision-making, and efficiency in construction project management.

Defining Site Survey in Construction

Site survey in construction involves the detailed physical inspection and measurement of a location to gather accurate data on terrain, existing structures, and environmental conditions. This process establishes a foundational understanding for project planning, ensuring designs align with site realities. Precise site surveys reduce risks and enhance decision-making throughout the construction lifecycle.

Understanding Digital Twin Assessment

Digital Twin Assessment in construction involves creating a precise virtual replica of the physical site, integrating real-time data from IoT sensors and BIM models to monitor progress, detect discrepancies, and predict potential issues. This method enhances decision-making by providing dynamic insights into structural integrity, resource utilization, and environmental conditions throughout the project lifecycle. Unlike traditional site surveys, Digital Twin Assessment enables continuous analysis and simulation, improving accuracy and efficiency in construction management.

Key Differences Between Site Survey and Digital Twin Assessment

Site surveys provide real-time, on-the-ground data collection through physical inspections, essential for capturing immediate environmental conditions and verifying existing structures. Digital twin assessments use advanced 3D modeling and IoT sensor data to create a virtual replica of the construction site, enabling continuous monitoring and predictive analysis. The key difference lies in site surveys offering direct, manual data gathering, while digital twin assessments provide dynamic, data-driven simulations for proactive project management.

Benefits of Traditional Site Surveys

Traditional site surveys provide accurate, on-the-ground data collection essential for initial project planning and verification. They facilitate direct observation of physical conditions, enabling immediate identification of unforeseen challenges and precise measurements. These surveys also ensure compliance with local regulations through hands-on inspection, enhancing overall project reliability and safety.

Advantages of Digital Twin Assessment in Construction

Digital Twin Assessment in construction offers real-time, dynamic visualization of project sites, enabling precise monitoring and management of resources, timelines, and potential risks. Unlike traditional site surveys, digital twins integrate IoT sensor data and 3D modeling to simulate conditions, improving decision-making accuracy and reducing costly errors. This technology enhances collaboration across teams by providing a centralized, continuously updated digital replica, optimizing efficiency and project outcomes.

When to Use Site Survey vs Digital Twin Assessment

Site surveys are essential for capturing precise physical measurements and on-site conditions during initial project phases or when real-time monitoring is unavailable. Digital twin assessments excel in ongoing project management by utilizing real-time data for predictive maintenance, simulation, and virtual collaboration. Use site surveys for initial data accuracy and digital twins for dynamic, continuous analysis and decision-making throughout construction.

Impact on Project Planning and Management

Site surveys provide accurate on-ground data essential for initial project planning, enabling precise measurements and real-time condition assessments. Digital twin assessments offer dynamic, real-time simulations that enhance project management through predictive analytics and scenario testing, reducing risks and optimizing resource allocation. Combining site survey data with digital twins facilitates improved decision-making, streamlined workflows, and enhanced project timelines in construction management.

Technology Integration in Assessment Processes

Site surveys rely on traditional tools such as total stations and laser scanners to capture precise physical measurements, while digital twin assessments utilize IoT sensors, BIM models, and real-time data integration for comprehensive virtual replicas. The integration of advanced technologies in digital twin assessments enables continuous monitoring, predictive analytics, and improved decision-making throughout the construction lifecycle. Leveraging cloud computing and AI algorithms enhances accuracy and efficiency, transforming assessment processes from static snapshots to dynamic, data-driven insights.

Future Trends in Construction Site Assessment

Digital Twin Assessment is transforming construction site evaluation by integrating real-time data with 3D modeling, enabling predictive analytics and enhanced project management accuracy. Unlike traditional Site Survey methods relying on manual measurements, digital twins facilitate continuous monitoring and simulation of construction progress, reducing risks and optimizing resource allocation. Future trends point to increased adoption of AI-driven digital twins combined with IoT sensors, fostering smarter, more efficient, and sustainable construction site assessments.

Related Important Terms

LiDAR Scanning

LiDAR scanning offers precise, high-resolution data for site surveys, enabling accurate topographic mapping and volume calculations essential for construction planning. Unlike traditional site surveys, digital twin assessments leverage LiDAR data to create dynamic, real-time 3D models that improve project monitoring and decision-making throughout the construction lifecycle.

Photogrammetry Mapping

Site survey uses traditional methods like GPS and total stations to gather spatial data, while digital twin assessment leverages photogrammetry mapping to create highly detailed, 3D digital replicas of construction sites. Photogrammetry mapping enables precise measurements and real-time updates, enhancing accuracy and efficiency in project planning and management compared to conventional site survey techniques.

Point Cloud Data

Point cloud data provides highly accurate, three-dimensional representations of construction sites, enabling precise measurements and thorough spatial analysis essential for both site surveys and digital twin assessments. While site surveys capture real-time physical conditions through laser scanning or photogrammetry, digital twin assessments leverage point cloud data to create dynamic, interactive models that integrate design, construction, and operational information for enhanced project management.

Geo-Referenced Survey

Geo-referenced site surveys capture precise spatial data on existing conditions, forming the foundational dataset for creating accurate digital twins. Digital twin assessments leverage this geo-referenced information to simulate, analyze, and optimize construction projects with real-time spatial accuracy.

Drone-Based Assessment

Drone-based site surveys provide high-resolution aerial imagery and real-time data collection for accurate topographic mapping, enabling efficient terrain analysis and progress monitoring. Digital twin assessments integrate this drone-collected data into a dynamic 3D model, allowing comprehensive simulations and predictive maintenance in construction project management.

As-Built Digital Twin

As-built digital twin assessments provide highly accurate, real-time 3D models of construction sites, enabling precise verification of structural elements compared to traditional site surveys that rely on manual measurements and visual inspections. The integration of laser scanning and IoT sensors in as-built digital twins enhances project efficiency by facilitating comprehensive condition monitoring, progress tracking, and predictive maintenance throughout the construction lifecycle.

BIM Integration

Site surveys provide real-world data essential for accurate Building Information Modeling (BIM) integration, capturing existing conditions through physical measurements. Digital twin assessments enhance BIM by creating dynamic, real-time models that enable continuous monitoring, predictive maintenance, and improved decision-making throughout the construction lifecycle.

4D/5D Simulation

Site surveys provide precise physical measurements crucial for accurate 4D/5D simulations by capturing real-world geometry and conditions, while digital twin assessments enhance these simulations by integrating real-time data and dynamic analytics for ongoing project optimization. Combining site survey accuracy with the dynamic capabilities of digital twins enables comprehensive construction planning, progress monitoring, and cost management throughout the project lifecycle.

Reality Capture

Site surveys rely on traditional manual measurements and visual inspections, often leading to limited data scope and potential human error, while digital twin assessments utilize advanced reality capture technologies such as 3D laser scanning and photogrammetry to create highly accurate, dynamic virtual models of construction sites. These digital twins enable real-time monitoring, predictive analytics, and detailed spatial analysis, significantly enhancing project accuracy, efficiency, and decision-making throughout the construction lifecycle.

Sensor-Driven Monitoring

Sensor-driven monitoring in site surveys captures real-time environmental and structural data to ensure accuracy in construction progress tracking, while digital twin assessments create virtual replicas integrating sensor inputs for predictive analytics and enhanced decision-making. Combining these technologies optimizes resource allocation, reduces risks, and improves operational efficiency throughout the construction lifecycle.

Site Survey vs Digital Twin Assessment Infographic

industrydif.com

industrydif.com