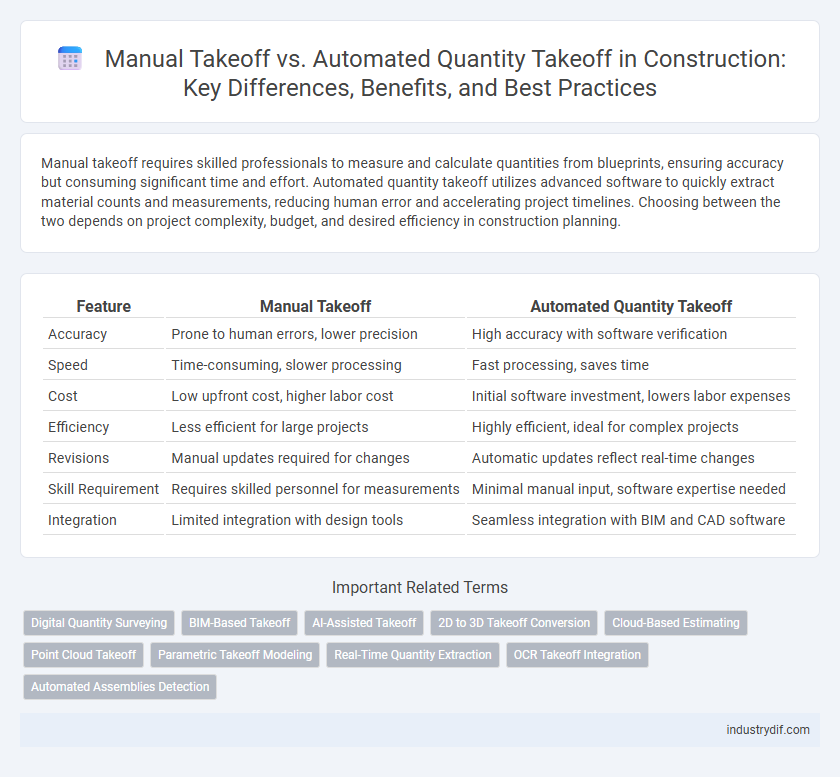

Manual takeoff requires skilled professionals to measure and calculate quantities from blueprints, ensuring accuracy but consuming significant time and effort. Automated quantity takeoff utilizes advanced software to quickly extract material counts and measurements, reducing human error and accelerating project timelines. Choosing between the two depends on project complexity, budget, and desired efficiency in construction planning.

Table of Comparison

| Feature | Manual Takeoff | Automated Quantity Takeoff |

|---|---|---|

| Accuracy | Prone to human errors, lower precision | High accuracy with software verification |

| Speed | Time-consuming, slower processing | Fast processing, saves time |

| Cost | Low upfront cost, higher labor cost | Initial software investment, lowers labor expenses |

| Efficiency | Less efficient for large projects | Highly efficient, ideal for complex projects |

| Revisions | Manual updates required for changes | Automatic updates reflect real-time changes |

| Skill Requirement | Requires skilled personnel for measurements | Minimal manual input, software expertise needed |

| Integration | Limited integration with design tools | Seamless integration with BIM and CAD software |

Introduction to Quantity Takeoff in Construction

Quantity takeoff in construction involves accurately measuring materials and labor required for a project, forming the foundation for cost estimation and project planning. Manual takeoff relies on traditional methods such as blueprints and physical measurements, which can be time-consuming and prone to human error. Automated quantity takeoff utilizes software and digital tools to enhance precision, speed, and efficiency in calculating quantities from digital plans.

Defining Manual Takeoff Methods

Manual takeoff methods in construction involve manually measuring and quantifying materials from blueprints or digital plans, relying on physical tools like rulers and scale drawings. This process requires skilled estimators to interpret drawings accurately and calculate quantities by hand, which can be time-consuming and prone to human error. Despite its traditional use, manual takeoff demands meticulous attention to detail to ensure precise project costing and resource planning.

Understanding Automated Quantity Takeoff

Automated quantity takeoff leverages advanced software tools to extract precise material quantities directly from digital blueprints, significantly reducing human error and saving time. Utilizing BIM (Building Information Modeling) and AI-driven algorithms, this method enhances accuracy by providing real-time updates and seamless integration with project management systems. Embracing automated quantity takeoff drives efficiency in cost estimation, procurement planning, and resource allocation throughout the construction lifecycle.

Accuracy Comparison: Manual vs Automated Takeoff

Manual takeoff relies heavily on human interpretation, increasing the risk of errors and inconsistencies in quantity estimation, especially on complex construction projects. Automated quantity takeoff uses advanced software algorithms to analyze digital plans, significantly enhancing accuracy by reducing manual data entry mistakes and ensuring consistent measurements. Studies show automated systems improve precision by up to 30%, minimizing costly overruns and project delays.

Time Efficiency: Traditional vs Digital Processes

Manual takeoff in construction often requires extensive time and labor due to the need for precise measurements and calculations, increasing project timelines and the risk of human error. Automated quantity takeoff leverages digital tools and software to instantly calculate material quantities from project plans, significantly reducing processing time while improving accuracy. This shift from traditional to digital methods enhances overall time efficiency, enabling faster decision-making and streamlined project management.

Cost Implications of Each Method

Manual takeoff involves labor-intensive measurement and calculation processes, often resulting in higher labor costs and longer project timelines. Automated quantity takeoff leverages software tools that reduce human error, accelerate calculations, and lower overall labor costs, although initial software investment and training expenses may apply. Cost savings from automation are typically realized through improved accuracy, faster project completion, and reduced rework compared to manual methods.

Human Error and Risk Management

Manual takeoff in construction is highly prone to human error, leading to inaccuracies in material quantities and project cost estimations, which significantly increases risk management challenges. Automated quantity takeoff systems utilize advanced software algorithms and digital blueprints to minimize these errors, enhancing precision and reducing the likelihood of costly overruns and project delays. Integrating automated solutions improves overall risk mitigation by providing reliable data for budgeting, procurement, and scheduling decisions.

Integration with Construction Software

Manual takeoff requires extensive data entry and is prone to human error, limiting its seamless integration with modern construction software platforms like Procore or Autodesk BIM 360. Automated quantity takeoff excels in directly extracting measurements from digital blueprints, enabling real-time updates and synchronization with project management tools. Integration between automated takeoff tools and construction software enhances accuracy, accelerates project timelines, and improves resource allocation.

Adapting to Industry Digital Transformation

Manual takeoff requires extensive labor and is prone to human error, slowing project timelines and increasing costs. Automated quantity takeoff leverages digital tools such as BIM and AI to rapidly generate accurate material quantities, improving efficiency and reducing waste. Embracing automated solutions accelerates adaptation to the construction industry's ongoing digital transformation, enhancing project management and resource allocation.

Future Trends in Quantity Takeoff Technology

Future trends in quantity takeoff technology emphasize integration of AI-driven software for enhanced accuracy and speed in material estimation. Cloud-based platforms enable real-time collaboration and seamless updates, reducing project delays and errors. Machine learning algorithms predict project needs by analyzing historical data, optimizing resource allocation and cost management in construction projects.

Related Important Terms

Digital Quantity Surveying

Manual takeoff in construction involves physically measuring plans and calculating quantities, which is time-consuming and prone to human error, whereas automated quantity takeoff utilizes advanced digital tools and software to quickly extract accurate quantities from digital drawings, enhancing efficiency in digital quantity surveying. Digital quantity surveying leverages Building Information Modeling (BIM) and specialized software like Bluebeam Revu and Autodesk Quantity Takeoff to streamline cost estimation and project management by providing precise, real-time data integration.

BIM-Based Takeoff

BIM-based takeoff automates quantity extraction by leveraging 3D building models to deliver precise material and labor measurements compared to manual takeoff methods that rely on 2D drawings and human estimation. This technology reduces errors, accelerates project timelines, and integrates seamlessly with construction management systems for enhanced cost control and resource allocation.

AI-Assisted Takeoff

AI-assisted takeoff significantly enhances accuracy and efficiency in construction quantity estimation by automatically extracting precise measurements from digital blueprints. Unlike manual takeoff, this technology reduces human error and accelerates project timelines by leveraging machine learning algorithms to interpret complex designs and update material quantities in real-time.

2D to 3D Takeoff Conversion

Manual takeoff relies on interpreting 2D blueprints to measure quantities, which often leads to time-consuming processes and higher risks of human error in complex projects. Automated quantity takeoff leverages advanced 3D modeling software to convert 2D drawings into detailed 3D models, enabling precise material estimation, increased accuracy, and faster project turnaround times.

Cloud-Based Estimating

Cloud-based estimating platforms streamline quantity takeoff processes by enabling real-time collaboration, reducing human error, and accelerating project timelines compared to manual takeoff methods. Automated quantity takeoff integrated with cloud technology enhances data accuracy, facilitates instant updates, and supports scalable resource management for construction projects.

Point Cloud Takeoff

Point Cloud Takeoff leverages 3D laser scanning data to generate highly accurate material quantities, significantly reducing errors compared to traditional Manual Takeoff methods that rely on 2D drawings and human measurements. Automated Quantity Takeoff from point clouds accelerates project estimation, enhances precision in volume calculations, and enables real-time updates, improving overall construction project efficiency and cost control.

Parametric Takeoff Modeling

Parametric Takeoff Modeling enhances both manual and automated quantity takeoff by integrating dynamic data inputs with 3D models, ensuring precise material estimates and reducing errors caused by manual measurements. This approach streamlines construction planning by automatically updating quantities as design parameters change, leading to more accurate budgeting and resource allocation.

Real-Time Quantity Extraction

Manual takeoff relies on human measurement and interpretation of blueprints, which can lead to delays and errors in real-time quantity extraction during construction planning. Automated quantity takeoff uses software solutions with AI and BIM integration to instantly generate precise material quantities, enhancing accuracy and efficiency in project estimations.

OCR Takeoff Integration

OCR takeoff integration streamlines quantity takeoff by automatically extracting measurements from scanned blueprints and construction documents, significantly reducing manual data entry errors and saving time. This technology enhances accuracy compared to traditional manual takeoff methods by quickly converting visual information into precise material quantities for project estimation and planning.

Automated Assemblies Detection

Automated assemblies detection in quantity takeoff leverages advanced algorithms and machine learning to rapidly identify and quantify grouped construction elements, significantly reducing human error and accelerating project estimates. This technology integrates with BIM models to enhance accuracy by automatically recognizing complex assemblies, streamlining material ordering and cost forecasting processes.

Manual Takeoff vs Automated Quantity Takeoff Infographic

industrydif.com

industrydif.com