Steel rebar offers high tensile strength and durability, making it a standard choice in reinforced concrete structures, but it is prone to corrosion over time, especially in harsh environments. Composite rebar, made from fiberglass or carbon fibers, provides excellent corrosion resistance and lightweight properties, enhancing the longevity and ease of handling on construction sites. Both materials impact structural integrity and cost; selecting between steel and composite rebar depends on project-specific requirements such as environmental exposure and budget constraints.

Table of Comparison

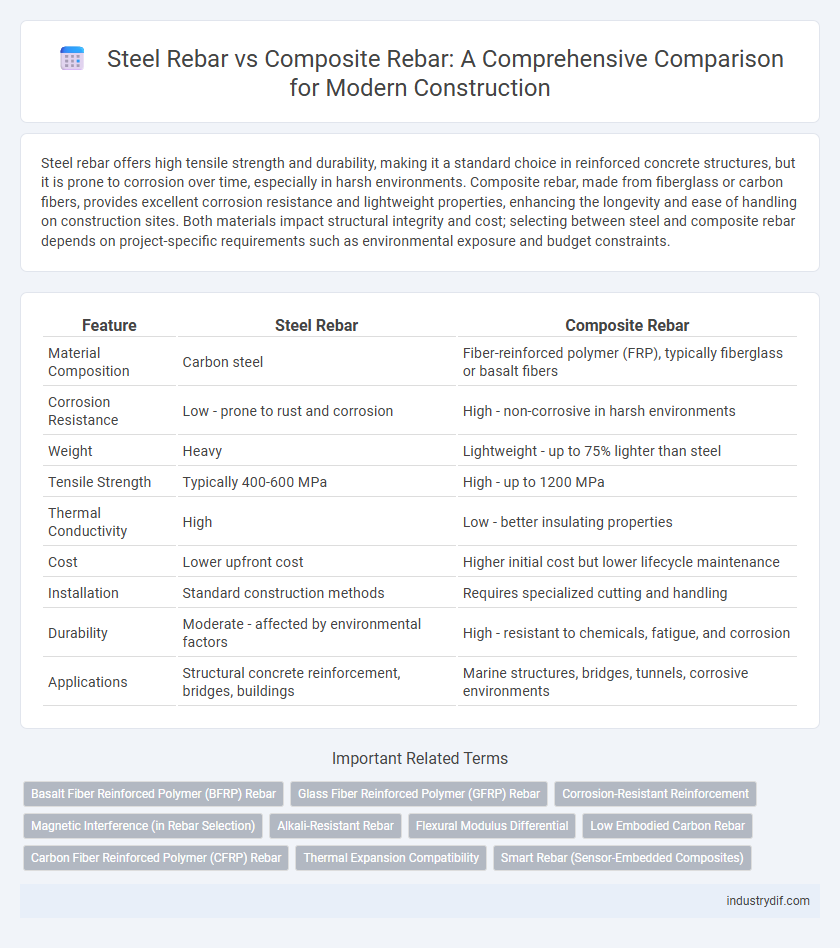

| Feature | Steel Rebar | Composite Rebar |

|---|---|---|

| Material Composition | Carbon steel | Fiber-reinforced polymer (FRP), typically fiberglass or basalt fibers |

| Corrosion Resistance | Low - prone to rust and corrosion | High - non-corrosive in harsh environments |

| Weight | Heavy | Lightweight - up to 75% lighter than steel |

| Tensile Strength | Typically 400-600 MPa | High - up to 1200 MPa |

| Thermal Conductivity | High | Low - better insulating properties |

| Cost | Lower upfront cost | Higher initial cost but lower lifecycle maintenance |

| Installation | Standard construction methods | Requires specialized cutting and handling |

| Durability | Moderate - affected by environmental factors | High - resistant to chemicals, fatigue, and corrosion |

| Applications | Structural concrete reinforcement, bridges, buildings | Marine structures, bridges, tunnels, corrosive environments |

Introduction to Steel Rebar and Composite Rebar

Steel rebar consists of carbon steel bars with ribbed surfaces to enhance bonding with concrete, widely used in construction for its high tensile strength and durability. Composite rebar, made from materials like fiberglass or basalt fibers embedded in a resin matrix, offers corrosion resistance and lighter weight compared to traditional steel. Both types serve as reinforcement in concrete structures, with steel rebar preferred in high-stress applications and composite rebar favored in environments prone to corrosion.

Material Composition and Properties

Steel rebar is primarily composed of carbon steel, offering high tensile strength and excellent ductility, which enhances structural integrity under stress. Composite rebar, typically made from fiberglass or basalt fibers embedded in a resin matrix, provides superior corrosion resistance and lightweight properties compared to steel. The material composition directly influences durability, with composite rebar excelling in environments prone to corrosion, while steel rebar maintains superior load-bearing capacity.

Strength and Durability Comparison

Steel rebar offers high tensile strength and excellent ductility, making it ideal for heavy-load structural applications, while composite rebar, typically made from fiberglass or carbon fibers, provides superior corrosion resistance and lighter weight. Composite rebar maintains its integrity in harsh environmental conditions, extending the lifespan of concrete structures by preventing rust-related deterioration commonly seen in steel rebar. Both materials contribute significantly to construction durability, but composite rebar excels in environments prone to chemical exposure, and steel rebar remains preferred for its proven mechanical strength under dynamic stresses.

Corrosion Resistance and Longevity

Composite rebar exhibits superior corrosion resistance compared to steel rebar due to its non-metallic composition, which prevents rust and degradation in harsh environments. This enhanced corrosion resistance directly translates to greater longevity in concrete structures, reducing maintenance costs and extending service life. Steel rebar, while strong, is prone to corrosion when exposed to moisture and chlorides, compromising structural integrity over time.

Weight and Handling Considerations

Steel rebar typically weighs more than composite rebar, making it heavier to transport and handle on construction sites. Composite rebar, often made from fiberglass or carbon fibers, offers a significant reduction in weight, which enhances ease of installation and reduces labor costs. Lighter composite rebar also lowers the risk of worker fatigue and injury, improving site safety and efficiency.

Cost Analysis: Initial and Lifecycle

Steel rebar typically offers lower initial costs compared to composite rebar, making it a popular choice for budget-sensitive construction projects. Composite rebar, although more expensive upfront, provides superior corrosion resistance and reduces maintenance expenses over the structure's lifecycle. Lifecycle cost analysis shows that composite rebar can result in significant long-term savings by minimizing repair and replacement needs in aggressive environmental conditions.

Applications in Modern Construction

Steel rebar remains the preferred choice for high-strength structural applications such as bridges, high-rise buildings, and heavy infrastructure due to its superior tensile strength and ductility. Composite rebar, often made from fiberglass or carbon fiber, excels in corrosive environments like marine structures, parking garages, and chemical plants because of its resistance to rust and chemical degradation. Modern construction increasingly leverages composite rebar for lightweight, non-conductive projects while relying on steel rebar for load-bearing frameworks requiring proven durability.

Environmental Impact and Sustainability

Steel rebar, while durable and widely used in construction, involves high energy consumption and significant carbon emissions during production, contributing to environmental degradation. Composite rebar, typically made from fiberglass or basalt fibers combined with resins, offers superior corrosion resistance and reduces resource extraction, leading to a lower carbon footprint and extended service life. The sustainability of composite rebar is enhanced by its recyclability and reduced maintenance needs, making it a greener alternative for eco-conscious construction projects.

Installation Methods and Best Practices

Steel rebar installation demands precise cutting, bending, and tying using tools like rebar cutters and tie wire to ensure structural integrity and corrosion resistance. Composite rebar, often made from fiberglass or carbon fiber, requires specialized cutting equipment such as diamond blades and is secured with epoxy or mechanical fasteners to prevent damage during installation. Best practices include adhering to manufacturer guidelines, maintaining proper spacing, and ensuring compatibility with concrete mix design to optimize bonding and longevity.

Industry Standards and Regulatory Compliance

Steel rebar complies with established industry standards such as ASTM A615 and A706, ensuring structural integrity and performance under various load conditions. Composite rebar, often made from fiberglass or carbon fiber, must meet specific standards like ACI 440.3R to guarantee corrosion resistance and durability in harsh environments. Regulatory compliance mandates rigorous testing and certification processes for both materials to align with building codes and safety requirements.

Related Important Terms

Basalt Fiber Reinforced Polymer (BFRP) Rebar

Basalt Fiber Reinforced Polymer (BFRP) rebar offers superior corrosion resistance and higher tensile strength compared to traditional steel rebar, making it ideal for structures exposed to harsh environmental conditions. BFRP rebar also reduces overall maintenance costs and extends the lifespan of concrete infrastructures, enhancing durability in marine and chemically aggressive environments.

Glass Fiber Reinforced Polymer (GFRP) Rebar

Glass Fiber Reinforced Polymer (GFRP) rebar offers superior corrosion resistance compared to traditional steel rebar, making it ideal for marine and chemical-exposed construction environments. GFRP rebar also provides a high strength-to-weight ratio and non-conductive properties, reducing maintenance costs and enhancing structural longevity in reinforced concrete applications.

Corrosion-Resistant Reinforcement

Composite rebar offers superior corrosion resistance compared to traditional steel rebar, significantly enhancing the durability of reinforced concrete structures in harsh environments such as marine or chemically aggressive settings. Its non-metallic, fiber-reinforced polymer composition prevents rusting, reducing maintenance costs and extending the lifespan of infrastructure projects.

Magnetic Interference (in Rebar Selection)

Steel rebar can cause significant magnetic interference in sensitive environments such as hospitals or laboratories, potentially disrupting electronic equipment and imaging devices. Composite rebar, composed of non-metallic materials like fiberglass or carbon fiber, offers a non-magnetic alternative that eliminates such interference while maintaining structural strength.

Alkali-Resistant Rebar

Alkali-resistant composite rebar offers superior corrosion resistance compared to traditional steel rebar, making it ideal for concrete structures exposed to harsh environments and increasing longevity. Its non-metallic composition, typically fiberglass reinforced polymer (FRP), prevents rusting and reduces maintenance costs while maintaining high tensile strength for structural integrity.

Flexural Modulus Differential

Steel rebar exhibits a higher flexural modulus compared to composite rebar, resulting in greater stiffness and resistance to bending under load. Composite rebar, typically made from fiberglass or carbon fiber, offers a lower flexural modulus which enhances flexibility and reduces brittleness, making it suitable for applications requiring corrosion resistance and lightweight reinforcement.

Low Embodied Carbon Rebar

Low embodied carbon rebar significantly reduces environmental impact compared to traditional steel rebar by utilizing recycled materials and innovative manufacturing processes. Composite rebar, often made from fiberglass or basalt fibers, offers corrosion resistance and lightweight benefits, further lowering the carbon footprint in sustainable construction projects.

Carbon Fiber Reinforced Polymer (CFRP) Rebar

Carbon Fiber Reinforced Polymer (CFRP) rebar offers superior corrosion resistance, high tensile strength, and lightweight properties compared to traditional steel rebar, making it ideal for structures exposed to harsh environments. CFRP rebar's non-conductive nature and longer lifespan reduce maintenance costs and enhance the durability of concrete infrastructure projects.

Thermal Expansion Compatibility

Steel rebar exhibits a thermal expansion coefficient closely matching that of concrete, minimizing internal stresses caused by temperature fluctuations and preserving structural integrity. Composite rebar, often made from fiberglass or basalt fibers, has a lower thermal expansion rate than steel but may result in differential movement within concrete, potentially leading to cracks or bond degradation over time.

Smart Rebar (Sensor-Embedded Composites)

Smart rebar, a sensor-embedded composite material, offers real-time structural health monitoring capabilities that traditional steel rebar lacks, enhancing safety and longevity in construction projects. Integrating fiber optic sensors or piezoelectric elements within composite rebar enables early detection of stress, corrosion, and strain, optimizing maintenance and reducing lifecycle costs.

Steel Rebar vs Composite Rebar Infographic

industrydif.com

industrydif.com