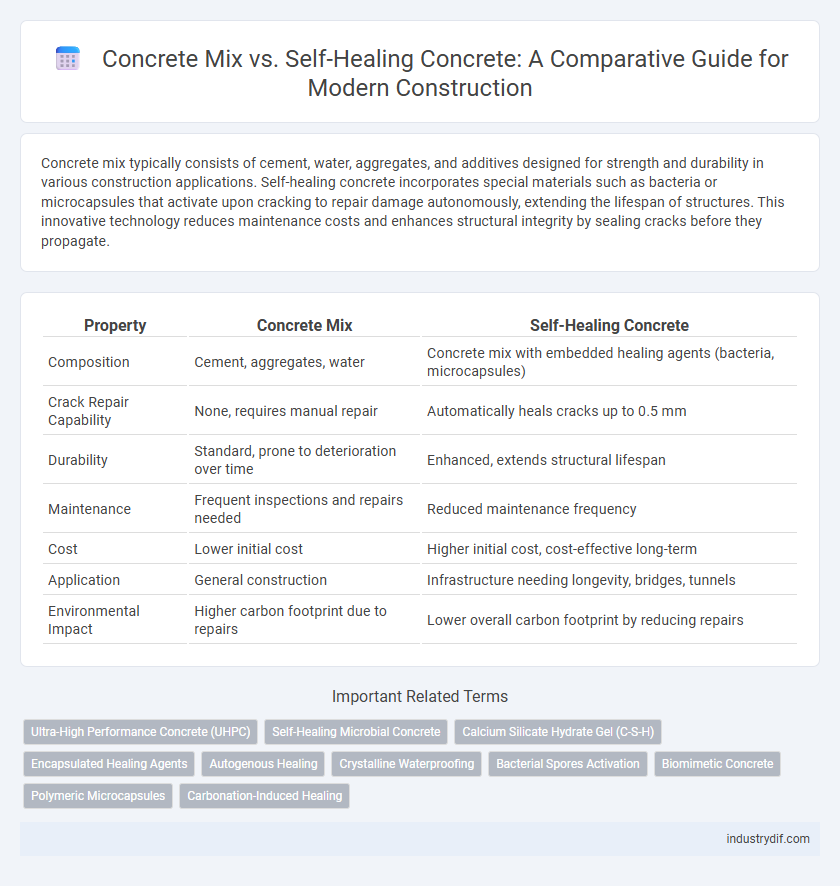

Concrete mix typically consists of cement, water, aggregates, and additives designed for strength and durability in various construction applications. Self-healing concrete incorporates special materials such as bacteria or microcapsules that activate upon cracking to repair damage autonomously, extending the lifespan of structures. This innovative technology reduces maintenance costs and enhances structural integrity by sealing cracks before they propagate.

Table of Comparison

| Property | Concrete Mix | Self-Healing Concrete |

|---|---|---|

| Composition | Cement, aggregates, water | Concrete mix with embedded healing agents (bacteria, microcapsules) |

| Crack Repair Capability | None, requires manual repair | Automatically heals cracks up to 0.5 mm |

| Durability | Standard, prone to deterioration over time | Enhanced, extends structural lifespan |

| Maintenance | Frequent inspections and repairs needed | Reduced maintenance frequency |

| Cost | Lower initial cost | Higher initial cost, cost-effective long-term |

| Application | General construction | Infrastructure needing longevity, bridges, tunnels |

| Environmental Impact | Higher carbon footprint due to repairs | Lower overall carbon footprint by reducing repairs |

Introduction to Concrete Mix and Self-Healing Concrete

Concrete mix consists of cement, aggregates, water, and additives carefully proportioned to achieve desired strength and durability for construction projects. Self-healing concrete incorporates special bacteria or chemical agents that activate upon crack formation, enabling the material to autonomously repair and extend structural lifespan. This innovative technology reduces maintenance costs and improves the sustainability of concrete infrastructure by minimizing deterioration over time.

Key Components of Traditional Concrete Mix

Traditional concrete mix primarily consists of cement, aggregates (sand and gravel), and water, with cement acting as the binder that hardens and holds the aggregate particles together. The proportions of these materials directly influence the concrete's strength, durability, and workability, making precise mixing essential for structural integrity. Admixtures like plasticizers or accelerators may be added to modify properties, but the core components remain critical in standard concrete formulations before the innovation of self-healing technologies.

How Self-Healing Concrete Works

Self-healing concrete contains microcapsules or bacteria that trigger a chemical reaction when cracks form, producing calcium carbonate to fill and seal the gaps autonomously. This innovative material enhances durability by reducing maintenance costs and extending the lifespan of structures. Traditional concrete lacks this capability, making it susceptible to water infiltration and subsequent damage over time.

Performance Comparison: Durability and Strength

Self-healing concrete exhibits superior durability compared to traditional concrete mixes by autonomously repairing micro-cracks, significantly reducing maintenance costs and extending structural lifespan. Traditional concrete mix relies on its initial strength, which can decrease over time due to crack propagation and environmental stressors. Performance tests reveal self-healing concrete maintains up to 30% higher compressive strength after damage repair, enhancing long-term structural integrity in construction projects.

Cost Analysis: Initial Investment vs Long-term Savings

Concrete mix presents a lower initial investment compared to self-healing concrete, which demands advanced materials and technology, increasing upfront costs by approximately 20-30%. Self-healing concrete significantly reduces long-term maintenance expenses by autonomously repairing cracks, potentially saving 40-60% on repair and labor costs over a 30-year lifespan. Cost analysis reveals that while traditional concrete offers budget-friendly installation, self-healing concrete ensures greater durability and economic benefits through decreased lifecycle expenditures.

Environmental Impact: Sustainability Considerations

Traditional concrete mix contributes significantly to carbon emissions due to its high cement content and energy-intensive production process. Self-healing concrete reduces environmental impact by extending structural lifespan and minimizing repair-related resource consumption. Incorporating bacteria or encapsulated healing agents in self-healing concrete improves sustainability through decreased maintenance and lower greenhouse gas emissions over time.

Application Areas in Modern Construction

Concrete mix is widely used for structural elements such as foundations, beams, slabs, and columns due to its cost-effectiveness and availability, making it suitable for residential, commercial, and infrastructure projects. Self-healing concrete is gaining traction in applications requiring enhanced durability and reduced maintenance, such as bridges, tunnels, and marine structures, where crack repair is critical for longevity. Both materials serve distinct roles in modern construction, with concrete mix dominating general use and self-healing concrete optimizing performance in specialized, high-stress environments.

Maintenance Requirements and Lifecycle

Concrete mix typically requires regular maintenance to address cracking and degradation over its lifecycle, including sealing and patching to extend durability. Self-healing concrete incorporates microcapsules or bacteria that activate upon damage, autonomously repairing cracks and significantly reducing maintenance needs. Lifecycle analysis shows self-healing concrete enhances structural longevity and decreases repair costs, offering a sustainable solution in construction projects.

Innovations Driving Self-Healing Concrete Adoption

Self-healing concrete integrates microcapsules, bacteria, or vascular networks that autonomously repair cracks, significantly extending the lifespan of structures and reducing maintenance costs. Innovations in material science and nanotechnology enable this concrete to respond dynamically to damage, enhancing durability and sustainability in construction projects. These advancements promote adoption by addressing critical issues of traditional concrete, such as crack propagation and structural degradation.

Future Trends in Concrete Technology

Self-healing concrete represents a significant advancement in concrete technology by incorporating microcapsules or bacteria that autonomously repair cracks, enhancing durability and reducing maintenance costs. Future trends emphasize integrating nanomaterials and smart sensors to monitor structural health in real-time, promoting sustainability and extending the lifespan of infrastructure. These innovations position self-healing concrete as a transformative solution for resilient and cost-effective construction projects worldwide.

Related Important Terms

Ultra-High Performance Concrete (UHPC)

Ultra-High Performance Concrete (UHPC) exhibits superior durability and mechanical properties compared to conventional concrete mix, incorporating fine powders, fibers, and optimized particle packing to achieve compressive strengths exceeding 150 MPa. Self-healing concrete integrates encapsulated healing agents or bacteria within UHPC matrices to autonomously repair microcracks, enhancing longevity and reducing maintenance costs in infrastructure applications.

Self-Healing Microbial Concrete

Self-healing microbial concrete incorporates bacteria that precipitate calcium carbonate, enabling automatic crack repair and extending structural durability compared to traditional concrete mix. This innovative material reduces maintenance costs and enhances sustainability by minimizing the need for manual repairs and preventing water infiltration.

Calcium Silicate Hydrate Gel (C-S-H)

Calcium Silicate Hydrate (C-S-H) gel is the primary binding phase in traditional concrete mixes, providing essential strength and durability through its dense microstructure. In self-healing concrete, C-S-H gel formation is enhanced during crack repair processes, facilitating autonomous recovery of structural integrity by filling microcracks and preventing further deterioration.

Encapsulated Healing Agents

Concrete mix with encapsulated healing agents provides a proactive solution to micro-crack repair by releasing healing materials upon damage, enhancing durability and reducing maintenance costs. Self-healing concrete leverages these capsules to extend structural lifespan and improve long-term performance compared to traditional concrete mix without such technology.

Autogenous Healing

Self-healing concrete utilizes autogenous healing, a natural process where unhydrated cement particles react with water to seal cracks, enhancing durability compared to traditional concrete mix that relies solely on external maintenance. This intrinsic repair ability reduces permeability and extends the lifespan of structures by minimizing microcrack propagation.

Crystalline Waterproofing

Crystalline waterproofing enhances self-healing concrete by filling micro-cracks with insoluble crystals that prevent water ingress, significantly extending structural durability compared to traditional concrete mixes. This technology reduces maintenance costs and improves resilience in construction projects exposed to harsh environmental conditions.

Bacterial Spores Activation

Concrete mix formulations typically rely on traditional curing processes, whereas self-healing concrete incorporates bacterial spores that activate upon crack exposure to produce calcium carbonate, sealing cracks autonomously. This biological mechanism enhances durability and extends the lifespan of infrastructure by preventing water ingress and reducing maintenance costs.

Biomimetic Concrete

Biomimetic concrete, a type of self-healing concrete, incorporates bacteria or chemical agents that activate upon crack formation, promoting calcium carbonate precipitation to autonomously seal fissures and enhance durability. Unlike traditional concrete mixes that require manual repair and are prone to structural degradation, biomimetic concrete extends service life, reduces maintenance costs, and improves sustainability in construction projects.

Polymeric Microcapsules

Polymeric microcapsules embedded in self-healing concrete release healing agents upon crack formation, significantly enhancing durability compared to traditional concrete mix that lacks autonomous repair mechanisms. This innovative technology reduces maintenance costs and extends structural lifespan by autonomously sealing microcracks in infrastructure applications.

Carbonation-Induced Healing

Concrete mix enhanced with self-healing properties significantly improves resistance to carbonation by autonomously sealing microcracks, thereby reducing CO2 ingress and prolonging structural durability. Unlike traditional concrete, self-healing concrete leverages encapsulated healing agents or bacteria that activate upon carbonation-induced damage, promoting sustainable infrastructure with lower maintenance costs.

Concrete Mix vs Self-Healing Concrete Infographic

industrydif.com

industrydif.com