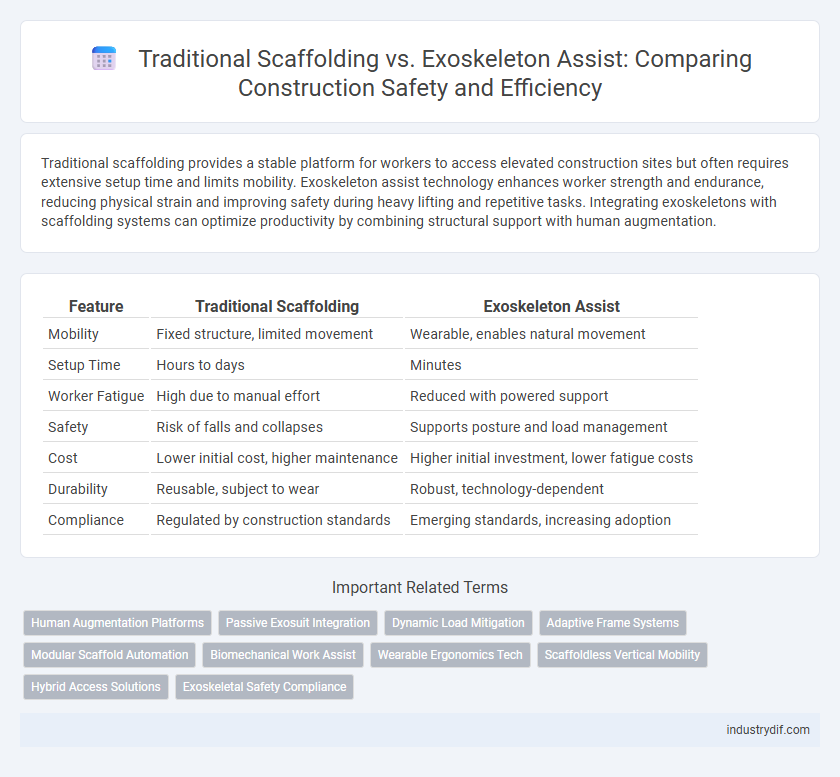

Traditional scaffolding provides a stable platform for workers to access elevated construction sites but often requires extensive setup time and limits mobility. Exoskeleton assist technology enhances worker strength and endurance, reducing physical strain and improving safety during heavy lifting and repetitive tasks. Integrating exoskeletons with scaffolding systems can optimize productivity by combining structural support with human augmentation.

Table of Comparison

| Feature | Traditional Scaffolding | Exoskeleton Assist |

|---|---|---|

| Mobility | Fixed structure, limited movement | Wearable, enables natural movement |

| Setup Time | Hours to days | Minutes |

| Worker Fatigue | High due to manual effort | Reduced with powered support |

| Safety | Risk of falls and collapses | Supports posture and load management |

| Cost | Lower initial cost, higher maintenance | Higher initial investment, lower fatigue costs |

| Durability | Reusable, subject to wear | Robust, technology-dependent |

| Compliance | Regulated by construction standards | Emerging standards, increasing adoption |

Introduction to Scaffolding and Exoskeleton Assist

Traditional scaffolding provides a temporary framework around construction sites, enabling workers to access elevated areas safely and efficiently. Exoskeleton assist technology involves wearable robotic suits designed to support physical movements, reduce fatigue, and enhance worker strength on site. Integrating exoskeletons with scaffolding practices can improve worker safety, increase productivity, and reduce musculoskeletal injuries in construction environments.

Core Differences: Structure and Technology

Traditional scaffolding relies on a fixed framework of metal or wooden poles assembled around the construction site, providing manual support and access for workers. Exoskeleton assist technology integrates wearable, motorized suits designed to enhance worker strength and reduce fatigue by supporting body movements during lifting and repetitive tasks. The core difference lies in scaffolding's static, external support, while exoskeletons offer dynamic, personal augmentation through advanced robotics and sensors.

Safety Standards and Worker Protection

Traditional scaffolding relies on sturdy, erected frames and guardrails to prevent falls, adhering to OSHA standards that mandate load capacities and regular inspections. Exoskeleton assist technology enhances worker protection by reducing musculoskeletal strain and improving stability, aligning with ANSI guidelines for wearable safety devices. Both methods improve safety, but exoskeletons offer proactive ergonomic support, minimizing injury risks beyond conventional fall prevention measures.

Efficiency in Installation and Dismantling

Traditional scaffolding requires extensive assembly time, often involving multiple workers and several hours to days for installation and dismantling. Exoskeleton assist technology streamlines these processes by enhancing worker mobility and strength, significantly reducing labor time and physical strain during setup and takedown. This efficiency gain leads to faster project timelines and lower labor costs on construction sites.

Cost Analysis: Upfront and Long-Term Investment

Traditional scaffolding requires significant upfront costs for materials, labor, and installation, with ongoing expenses for maintenance and storage. Exoskeleton assist technology demands a higher initial investment due to advanced mechanical components and training but offers long-term savings by enhancing worker productivity and reducing injury-related costs. Evaluating total cost of ownership reveals exoskeletons can lower operational expenses and improve ROI in extended construction projects.

Impact on Worker Productivity

Traditional scaffolding requires extensive manual setup and dismantling, which delays project timelines and reduces worker productivity. Exoskeleton assist technology enhances worker mobility and strength, enabling faster task completion and minimizing fatigue during overhead or repetitive activities. Studies indicate that integrating exoskeletons can increase productivity by up to 25% on construction sites compared to traditional scaffolding methods.

Adaptability to Complex Construction Projects

Traditional scaffolding offers limited adaptability in complex construction projects due to its fixed structures and extensive setup time, restricting access to intricate or elevated areas. Exoskeleton assist technology enhances worker mobility and strength, allowing efficient navigation and operation in challenging environments with irregular surfaces or confined spaces. Integrating exoskeletons with scaffold systems optimizes project workflow by combining physical support with flexible access, improving safety and productivity on-site.

Training and Skill Requirements

Traditional scaffolding demands extensive manual training in assembly, safety protocols, and structural stability to ensure worker safety and efficiency. Exoskeleton assist systems, while requiring less traditional construction skill, necessitate specialized training on mechanical operation, maintenance, and integration with existing workflows. The adoption of exoskeleton technology can reduce physical strain but calls for continuous skill development to optimize its benefits on construction sites.

Environmental and Site Footprint

Traditional scaffolding often requires extensive material use, including steel and timber, contributing to significant waste and a larger environmental footprint on construction sites. Exoskeleton assist technology minimizes the need for bulky structural setups by enhancing worker mobility and strength, thereby reducing materials consumption and site congestion. Implementing exoskeletons can optimize site footprint by lowering the space needed for equipment storage and scaffolding assembly, promoting more sustainable and efficient construction practices.

Future Trends in Construction Support Systems

Future trends in construction support systems emphasize the integration of exoskeleton assist technology to enhance worker safety and productivity, surpassing traditional scaffolding limitations. Advanced wearable exoskeletons offer ergonomic support and reduce physical strain, enabling extended work durations and minimizing injury risks on construction sites. Innovations in material science and wearable robotics are driving a shift from conventional scaffolding toward more adaptive, energy-efficient support solutions.

Related Important Terms

Human Augmentation Platforms

Traditional scaffolding provides static support structures for construction workers but limits mobility and efficiency, whereas exoskeleton assist systems enhance human strength, reduce fatigue, and improve ergonomic safety through advanced wearable robotics. Human augmentation platforms in construction integrate powered exoskeletons that boost lifting capacity and precision, leading to increased productivity and reduced risk of musculoskeletal injuries on job sites.

Passive Exosuit Integration

Traditional scaffolding provides stable platforms for workers but often limits mobility and increases setup time on construction sites. Passive exosuit integration enhances worker endurance and reduces physical strain by supporting body movements without requiring power sources, enabling safer and more efficient manual labor in complex environments.

Dynamic Load Mitigation

Traditional scaffolding relies on static load support, which often results in limited flexibility and increased risk of structural stress under dynamic loads. Exoskeleton assist systems enhance dynamic load mitigation by actively distributing weight and reducing worker strain, leading to improved safety and efficiency in construction projects.

Adaptive Frame Systems

Adaptive frame systems in traditional scaffolding offer modular configurations that provide stability and load-bearing capacity for various construction tasks, but they often require significant manual assembly and adjustments. Exoskeleton assist technology integrates powered support with adaptive frames, enhancing worker mobility and reducing physical strain while maintaining structural adaptability and safety compliance on complex job sites.

Modular Scaffold Automation

Modular scaffold automation integrates advanced robotics and sensor technology to enhance the efficiency and safety of traditional scaffolding assembly, reducing manual labor and installation time. Exoskeleton assist suits complement this automation by providing workers with augmented strength and endurance, minimizing fatigue and injury risk during scaffold construction and adjustment.

Biomechanical Work Assist

Traditional scaffolding provides static support structures that enable workers to reach elevated areas but often require significant physical exertion and awkward postures, increasing the risk of musculoskeletal disorders. Exoskeleton assist systems offer biomechanical work assist by actively reducing joint load and muscle strain, enhancing worker endurance and safety during repetitive or heavy lifting tasks on construction sites.

Wearable Ergonomics Tech

Traditional scaffolding poses physical strain and limits mobility, increasing the risk of musculoskeletal injuries on construction sites. Exoskeleton assist technologies enhance wearable ergonomics by reducing fatigue, improving posture, and boosting worker efficiency through powered support systems.

Scaffoldless Vertical Mobility

Scaffoldless vertical mobility via exoskeleton assist enhances worker safety and efficiency by reducing reliance on bulky traditional scaffolding, enabling more agile and precise movements on construction sites. This technology minimizes setup time and physical strain, accelerating project timelines while maintaining strict compliance with safety regulations.

Hybrid Access Solutions

Hybrid access solutions in construction combine traditional scaffolding with exoskeleton assist technology, enhancing worker safety and efficiency by reducing physical strain and increasing mobility. Integrating lightweight, powered exoskeleton devices with modular scaffolding structures optimizes site adaptability and accelerates project timelines by enabling safer, sustained elevated work.

Exoskeletal Safety Compliance

Exoskeleton assist devices in construction enhance worker safety by reducing physical strain and minimizing the risk of musculoskeletal injuries, complying with stringent OSHA and ANSI safety standards. Unlike traditional scaffolding, exoskeletal technology offers dynamic support and ergonomic benefits while maintaining regulatory compliance through continuous monitoring and adaptive load management.

Traditional Scaffolding vs Exoskeleton Assist Infographic

industrydif.com

industrydif.com