Steel reinforcement offers exceptional tensile strength and durability for concrete structures, making it the traditional choice in construction projects requiring load-bearing capacity. Fiber-Reinforced Polymer (FRP) provides corrosion resistance and lightweight properties, enhancing structural longevity and reducing maintenance costs in harsh environments. Comparing both materials depends on factors such as environmental conditions, budget constraints, and specific structural requirements.

Table of Comparison

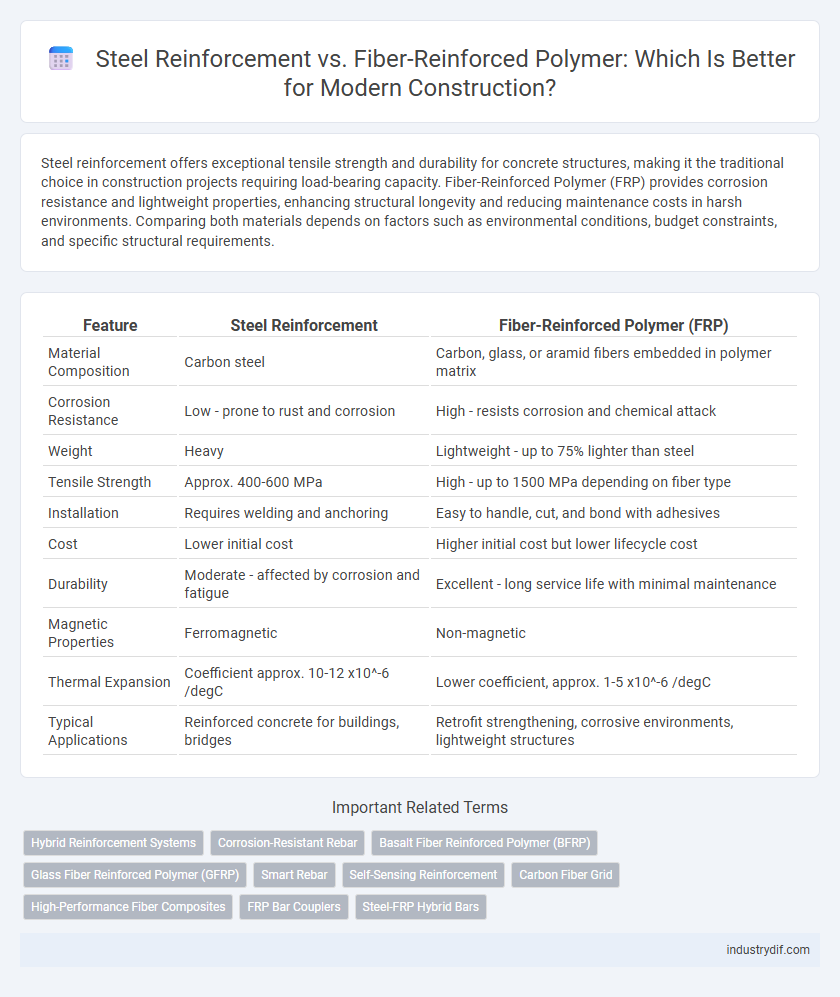

| Feature | Steel Reinforcement | Fiber-Reinforced Polymer (FRP) |

|---|---|---|

| Material Composition | Carbon steel | Carbon, glass, or aramid fibers embedded in polymer matrix |

| Corrosion Resistance | Low - prone to rust and corrosion | High - resists corrosion and chemical attack |

| Weight | Heavy | Lightweight - up to 75% lighter than steel |

| Tensile Strength | Approx. 400-600 MPa | High - up to 1500 MPa depending on fiber type |

| Installation | Requires welding and anchoring | Easy to handle, cut, and bond with adhesives |

| Cost | Lower initial cost | Higher initial cost but lower lifecycle cost |

| Durability | Moderate - affected by corrosion and fatigue | Excellent - long service life with minimal maintenance |

| Magnetic Properties | Ferromagnetic | Non-magnetic |

| Thermal Expansion | Coefficient approx. 10-12 x10^-6 /degC | Lower coefficient, approx. 1-5 x10^-6 /degC |

| Typical Applications | Reinforced concrete for buildings, bridges | Retrofit strengthening, corrosive environments, lightweight structures |

Introduction to Steel Reinforcement and Fiber-Reinforced Polymer

Steel reinforcement, traditionally used in construction, consists of steel bars or mesh embedded in concrete to enhance tensile strength and structural integrity. Fiber-Reinforced Polymer (FRP) composites, made from high-strength fibers such as carbon, glass, or aramid embedded in a polymer matrix, offer corrosion resistance and lightweight properties. Both materials serve critical roles in reinforcing concrete, with steel providing proven durability and FRP offering innovative solutions for environments prone to corrosion.

Material Composition and Properties

Steel reinforcement consists primarily of carbon steel with high tensile strength and excellent ductility, making it ideal for load-bearing applications in concrete structures. Fiber-Reinforced Polymer (FRP) is composed of strong synthetic fibers like glass, carbon, or aramid embedded in a polymer matrix, offering superior corrosion resistance and lightweight properties. While steel provides robust mechanical performance under tension and compression, FRP's non-corrosive nature enhances durability, especially in aggressive environments.

Mechanical Performance Comparison

Steel reinforcement exhibits superior tensile strength and ductility, making it highly effective for load-bearing structural applications. Fiber-reinforced polymer (FRP) offers high corrosion resistance and lightweight properties but generally has lower modulus of elasticity and creep resistance compared to steel. Mechanical performance assessments reveal steel's better long-term durability under cyclic loading, while FRP excels in environments prone to chemical exposure and moisture.

Corrosion Resistance and Durability

Steel reinforcement offers high tensile strength but is vulnerable to corrosion, which can compromise structural integrity over time, especially in harsh environmental conditions. Fiber-Reinforced Polymer (FRP) provides superior corrosion resistance due to its non-metallic composition, enhancing durability in marine, chemical, and high-moisture environments. The longevity of FRP reinforcements reduces maintenance costs and extends the service life of concrete structures compared to traditional steel.

Installation Techniques and Practical Considerations

Steel reinforcement installation requires precise bending, cutting, and tying of rebar to form a robust load-bearing framework within concrete structures, often necessitating skilled labor and heavy equipment. Fiber-Reinforced Polymer (FRP) systems typically utilize prefabricated sheets or bars that can be adhered, wrapped, or anchored to existing concrete surfaces, offering faster installation and corrosion resistance but requiring specialized adhesives and surface preparation. Practical considerations for steel include susceptibility to corrosion and heavy weight, while FRP demands careful environmental control during application and supports non-magnetic, lightweight reinforcement ideal for rehabilitation projects.

Cost Analysis and Lifecycle Value

Steel reinforcement offers a lower initial cost compared to fiber-reinforced polymer (FRP), making it a common choice for budget-focused construction projects. However, FRP provides superior corrosion resistance and durability, resulting in significantly reduced maintenance and longer lifecycle value. Considering total cost of ownership, FRP's higher upfront investment is offset by lower repair expenses and extended service life, enhancing overall economic efficiency.

Sustainability and Environmental Impact

Steel reinforcement offers high tensile strength and recyclability, yet its production involves significant carbon emissions and energy consumption. Fiber-Reinforced Polymer (FRP) materials provide corrosion resistance and reduced weight, contributing to longer structural lifespan and lower maintenance demands, which enhance sustainability. Life cycle assessments reveal that FRP's environmental impact is generally lower due to decreased resource use and extended durability compared to traditional steel reinforcement.

Application Areas in Modern Construction

Steel reinforcement remains the primary choice for structural elements in high-rise buildings, bridges, and heavy-load infrastructures due to its superior tensile strength and ductility. Fiber-Reinforced Polymer (FRP) is increasingly utilized in seismic retrofitting, corrosion-prone environments, and lightweight construction projects, offering advantages such as high corrosion resistance, ease of installation, and electromagnetic neutrality. Modern construction leverages steel reinforcement for foundational support while applying FRP composites in specialized applications like bridge deck overlays and structural strengthening of aging concrete.

Industry Standards and Regulatory Guidelines

Steel reinforcement complies with established industry standards such as ASTM A615 and A706, ensuring tensile strength, ductility, and weldability for concrete structures. Fiber-Reinforced Polymer (FRP) systems adhere to guidelines outlined in ACI 440.1R, focusing on corrosion resistance, lightweight properties, and non-magnetic behavior. Regulatory authorities emphasize compliance with local building codes and continuous testing to validate performance, durability, and fire resistance for both materials in construction applications.

Future Trends in Reinforcement Technology

Future trends in reinforcement technology emphasize the increasing use of Fiber-Reinforced Polymer (FRP) due to its superior corrosion resistance, lightweight properties, and high tensile strength compared to traditional steel reinforcement. Research highlights the integration of hybrid reinforcement systems combining steel and FRP to optimize structural performance and durability in harsh environments. Advancements in manufacturing techniques, like pultrusion and 3D printing for FRP, further enhance customization and efficiency in modern construction projects.

Related Important Terms

Hybrid Reinforcement Systems

Hybrid reinforcement systems combine steel reinforcement and fiber-reinforced polymers (FRP) to optimize structural performance, providing enhanced durability, corrosion resistance, and load-bearing capacity. These systems leverage the high tensile strength and ductility of steel with the lightweight, non-corrosive properties of FRP, resulting in improved longevity and reduced maintenance costs for concrete structures.

Corrosion-Resistant Rebar

Corrosion-resistant rebar, such as fiber-reinforced polymer (FRP), offers superior durability compared to traditional steel reinforcement by eliminating rust-related degradation, enhancing structural lifespan in corrosive environments. FRP rebar's lightweight and non-metallic properties reduce maintenance costs and improve performance in marine, chemical, and high-humidity construction applications.

Basalt Fiber Reinforced Polymer (BFRP)

Basalt Fiber Reinforced Polymer (BFRP) offers superior corrosion resistance and higher tensile strength compared to traditional steel reinforcement, making it ideal for structures exposed to harsh environmental conditions. Its lightweight and non-conductive properties reduce maintenance costs and improve structural durability in concrete applications.

Glass Fiber Reinforced Polymer (GFRP)

Glass Fiber Reinforced Polymer (GFRP) offers a lightweight, corrosion-resistant alternative to traditional steel reinforcement, significantly enhancing the durability of concrete structures in harsh environments. Its high tensile strength and non-conductive properties make GFRP ideal for applications requiring electromagnetic neutrality and reduced maintenance costs.

Smart Rebar

Smart Rebar integrates advanced sensors within traditional steel reinforcement to monitor stress, corrosion, and structural health in real-time, offering superior durability compared to Fiber-Reinforced Polymer (FRP) which primarily provides corrosion resistance and lightweight properties. Unlike FRP, Smart Rebar enables predictive maintenance through data-driven insights, significantly enhancing safety and longevity in construction projects.

Self-Sensing Reinforcement

Self-sensing reinforcement in construction leverages fiber-reinforced polymers (FRP) for real-time structural health monitoring by detecting strain and stress changes without external sensors. Unlike traditional steel reinforcement, FRP offers superior corrosion resistance and lightweight properties while enabling integrated sensing capabilities for improved durability and maintenance efficiency.

Carbon Fiber Grid

Carbon fiber grid in fiber-reinforced polymer (FRP) offers superior corrosion resistance and higher tensile strength compared to traditional steel reinforcement, making it ideal for enhancing the durability of concrete structures. Its lightweight and non-conductive properties improve installation efficiency and reduce maintenance costs in infrastructure projects.

High-Performance Fiber Composites

High-performance fiber composites in construction offer superior corrosion resistance and lightweight properties compared to traditional steel reinforcement, enhancing structural durability and reducing maintenance costs. Fiber-reinforced polymers (FRPs) provide high tensile strength and ease of installation, making them ideal for seismic retrofitting and infrastructure rehabilitation where long-term performance is critical.

FRP Bar Couplers

Fiber-Reinforced Polymer (FRP) bar couplers offer enhanced corrosion resistance and lightweight durability compared to traditional steel reinforcement, making them ideal for infrastructure in harsh environments. FRP couplers provide reliable load transfer and simplify installation by eliminating welding or lap splicing, improving structural integrity and reducing labor costs in reinforced concrete construction.

Steel-FRP Hybrid Bars

Steel-FRP hybrid bars combine the high tensile strength and durability of steel reinforcement with the corrosion resistance and lightweight properties of fiber-reinforced polymer, enhancing structural performance and longevity in concrete construction. These hybrid bars optimize load-bearing capacity and reduce maintenance costs, making them ideal for harsh environments and infrastructure requiring high durability.

Steel Reinforcement vs Fiber-Reinforced Polymer Infographic

industrydif.com

industrydif.com