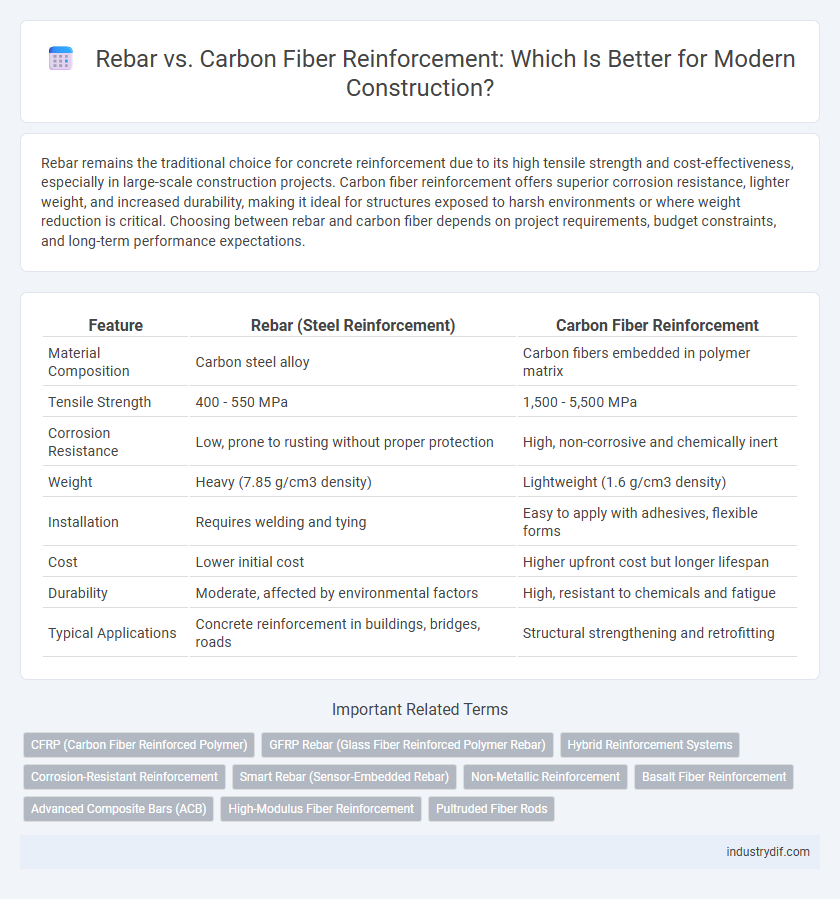

Rebar remains the traditional choice for concrete reinforcement due to its high tensile strength and cost-effectiveness, especially in large-scale construction projects. Carbon fiber reinforcement offers superior corrosion resistance, lighter weight, and increased durability, making it ideal for structures exposed to harsh environments or where weight reduction is critical. Choosing between rebar and carbon fiber depends on project requirements, budget constraints, and long-term performance expectations.

Table of Comparison

| Feature | Rebar (Steel Reinforcement) | Carbon Fiber Reinforcement |

|---|---|---|

| Material Composition | Carbon steel alloy | Carbon fibers embedded in polymer matrix |

| Tensile Strength | 400 - 550 MPa | 1,500 - 5,500 MPa |

| Corrosion Resistance | Low, prone to rusting without proper protection | High, non-corrosive and chemically inert |

| Weight | Heavy (7.85 g/cm3 density) | Lightweight (1.6 g/cm3 density) |

| Installation | Requires welding and tying | Easy to apply with adhesives, flexible forms |

| Cost | Lower initial cost | Higher upfront cost but longer lifespan |

| Durability | Moderate, affected by environmental factors | High, resistant to chemicals and fatigue |

| Typical Applications | Concrete reinforcement in buildings, bridges, roads | Structural strengthening and retrofitting |

Introduction to Construction Reinforcement Materials

Rebar and carbon fiber reinforcement serve as critical materials in construction for enhancing structural integrity. Rebar, composed of steel, is favored for its high tensile strength and cost-effectiveness in concrete reinforcement. Carbon fiber reinforcement offers superior corrosion resistance and lightweight properties, making it ideal for advanced or specialized construction applications.

Overview of Traditional Steel Rebar

Traditional steel rebar is the most widely used reinforcement material in concrete construction due to its high tensile strength, durability, and cost-effectiveness. It provides excellent bonding with concrete, ensuring structural integrity and resistance to compressive and tensile stresses in various building applications. Despite susceptibility to corrosion, surface treatments and coatings enhance the longevity of steel rebar in harsh environments.

What is Carbon Fiber Reinforcement?

Carbon fiber reinforcement consists of high-strength, lightweight carbon fibers embedded in a polymer matrix to enhance structural performance in construction. It offers superior tensile strength and corrosion resistance compared to traditional steel rebar, making it ideal for strengthening concrete structures and repairing existing elements. Its non-metallic properties reduce maintenance costs and extend the lifespan of infrastructure exposed to harsh environmental conditions.

Strength Comparison: Rebar vs Carbon Fiber

Carbon fiber reinforcement offers significantly higher tensile strength compared to traditional steel rebar, with tensile strength values reaching up to 7,000 MPa versus rebar's typical range of 400-1,200 MPa. Carbon fiber also exhibits superior corrosion resistance, maintaining structural integrity in harsh environments where steel rebar may degrade and weaken over time. Despite its higher initial cost, carbon fiber's strength-to-weight ratio provides enhanced performance in construction applications requiring lightweight yet durable reinforcement.

Durability and Longevity Factors

Rebar, typically made from steel, offers high tensile strength but is susceptible to corrosion, which can reduce the lifespan of concrete structures without adequate protective coatings. Carbon fiber reinforcement provides superior corrosion resistance and excellent durability in harsh environments, leading to longer service life and reduced maintenance costs. The choice between rebar and carbon fiber depends on project-specific factors such as exposure conditions, budget, and the expected structural lifespan.

Installation Process and Techniques

Rebar installation involves placing steel bars in concrete forms with precise spacing and securing them using ties or spacers to maintain structural integrity. Carbon fiber reinforcement requires surface preparation such as cleaning and sanding, followed by applying epoxy resin and embedding carbon fiber sheets or strips onto concrete surfaces using specialized techniques. The carbon fiber method offers faster curing times and reduced labor intensity compared to traditional rebar installation, enhancing efficiency in retrofitting and repair projects.

Cost Analysis: Short-Term vs Long-Term Investment

Rebar typically offers lower upfront costs compared to carbon fiber reinforcement, making it a preferred option for short-term budget constraints in construction projects. Carbon fiber, despite its higher initial investment, provides exceptional durability and corrosion resistance, reducing maintenance expenses and extending structural lifespan, resulting in better long-term cost efficiency. Evaluating total lifecycle costs, including installation, maintenance, and durability, is crucial for informed decision-making between rebar and carbon fiber reinforcement.

Environmental Impact and Sustainability

Carbon fiber reinforcement offers significant environmental benefits over traditional rebar by reducing carbon emissions and decreasing material usage due to its high strength-to-weight ratio. Rebar production involves energy-intensive processes, releasing substantial CO2, whereas carbon fiber manufacturing, while energy-intensive, results in lighter, longer-lasting structures that minimize maintenance and replacement needs. Sustainable construction increasingly favors carbon fiber reinforcement for its potential to lower overall environmental impact and enhance structural durability.

Common Applications in Construction Projects

Rebar is predominantly used in heavy concrete structures such as bridges, foundations, and high-rise buildings due to its high tensile strength and cost-effectiveness. Carbon fiber reinforcement is increasingly applied in retrofitting and strengthening existing structures, especially where corrosion resistance and lightweight solutions are critical. Both materials serve crucial roles in construction projects, with rebar suited for new builds and carbon fiber ideal for repair and seismic upgrades.

Future Trends in Reinforcement Technology

Future trends in reinforcement technology emphasize sustainable and high-performance materials, with carbon fiber reinforcement gaining traction due to its superior strength-to-weight ratio and corrosion resistance compared to traditional rebar. Advances in nanotechnology and hybrid composite reinforcement systems are driving innovation, enhancing durability and reducing maintenance costs in infrastructure projects. The integration of smart sensing technologies within reinforcement materials also allows real-time structural health monitoring, improving safety and extending the lifespan of concrete structures.

Related Important Terms

CFRP (Carbon Fiber Reinforced Polymer)

Carbon Fiber Reinforced Polymer (CFRP) offers superior tensile strength and corrosion resistance compared to traditional steel rebar, making it ideal for enhancing structural durability in harsh environments. Its lightweight nature and high modulus of elasticity allow for easier installation and reduced structural load without compromising reinforcement performance in concrete construction.

GFRP Rebar (Glass Fiber Reinforced Polymer Rebar)

GFRP rebar offers superior corrosion resistance and lightweight properties compared to traditional steel rebar, making it ideal for structures exposed to harsh environmental conditions. Its high tensile strength and electromagnetic neutrality improve longevity and reduce maintenance costs in concrete reinforcement applications.

Hybrid Reinforcement Systems

Hybrid reinforcement systems combine the tensile strength of carbon fiber with the ductility of traditional steel rebar, enhancing structural performance and corrosion resistance in concrete construction. Utilizing both materials optimizes load distribution and extends the lifespan of infrastructure by mitigating common issues such as cracking and degradation.

Corrosion-Resistant Reinforcement

Carbon fiber reinforcement offers superior corrosion resistance compared to traditional steel rebar, making it ideal for structures exposed to harsh environmental conditions or aggressive chemicals. Its non-metallic composition prevents rust and degradation, significantly extending the lifespan of concrete elements while reducing maintenance costs.

Smart Rebar (Sensor-Embedded Rebar)

Smart rebar integrates sensor technology within traditional steel reinforcement to provide real-time structural health monitoring, unlike carbon fiber reinforcement, which offers high tensile strength but lacks embedded sensing capabilities. This innovation enhances durability assessment and maintenance efficiency in construction projects, enabling proactive damage detection and optimized resource allocation.

Non-Metallic Reinforcement

Carbon fiber reinforcement offers superior tensile strength and corrosion resistance compared to traditional steel rebar, making it ideal for non-metallic reinforcement in concrete structures exposed to harsh environments. Its lightweight nature and electromagnetic neutrality reduce maintenance costs and improve structural longevity, particularly in marine and infrastructure applications.

Basalt Fiber Reinforcement

Basalt fiber reinforcement offers superior corrosion resistance and higher tensile strength compared to traditional rebar and carbon fiber, making it an optimal choice for enhancing structural durability in concrete construction. Its lightweight nature and excellent thermal stability contribute to improved load-bearing capacity and longer service life in infrastructure projects.

Advanced Composite Bars (ACB)

Advanced Composite Bars (ACB) offer superior corrosion resistance and tensile strength compared to traditional steel rebar, making them highly suitable for harsh environmental conditions in construction projects. The lightweight nature of ACB reduces structural load and facilitates easier handling and installation, while providing enhanced durability and longevity in reinforced concrete applications.

High-Modulus Fiber Reinforcement

High-modulus carbon fiber reinforcement offers superior tensile strength and corrosion resistance compared to traditional steel rebar, making it ideal for enhancing the durability of concrete structures in harsh environmental conditions. Its lightweight nature and high stiffness reduce structural weight while providing enhanced seismic performance and long-term durability in infrastructure projects.

Pultruded Fiber Rods

Pultruded fiber rods offer superior tensile strength and corrosion resistance compared to traditional steel rebar, making them ideal for reinforcing concrete structures in harsh environments. Their lightweight nature and non-conductive properties reduce installation time and increase durability, enhancing overall structural performance in construction projects.

Rebar vs Carbon Fiber Reinforcement Infographic

industrydif.com

industrydif.com