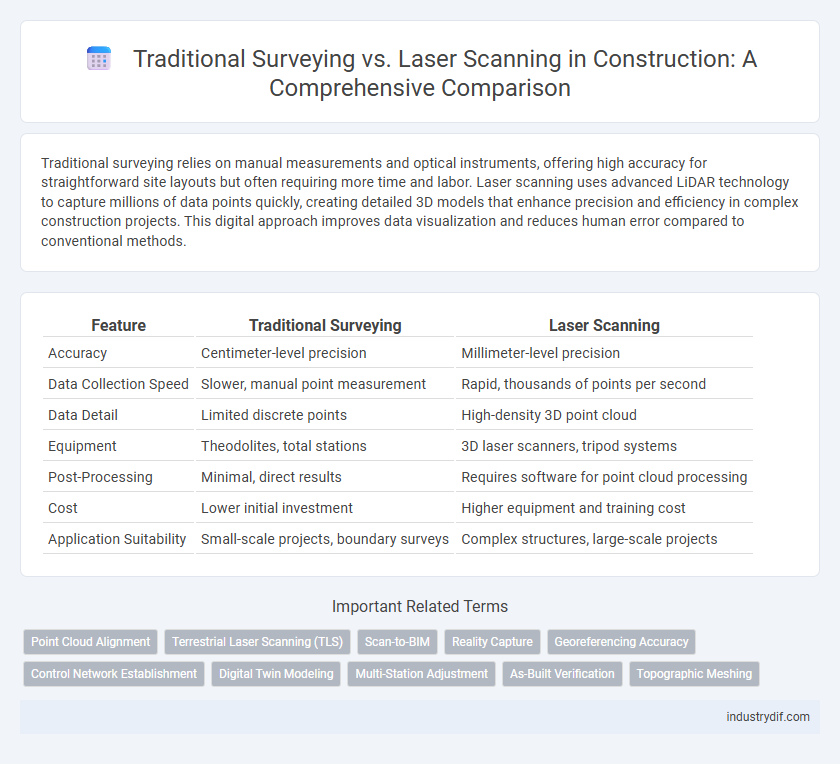

Traditional surveying relies on manual measurements and optical instruments, offering high accuracy for straightforward site layouts but often requiring more time and labor. Laser scanning uses advanced LiDAR technology to capture millions of data points quickly, creating detailed 3D models that enhance precision and efficiency in complex construction projects. This digital approach improves data visualization and reduces human error compared to conventional methods.

Table of Comparison

| Feature | Traditional Surveying | Laser Scanning |

|---|---|---|

| Accuracy | Centimeter-level precision | Millimeter-level precision |

| Data Collection Speed | Slower, manual point measurement | Rapid, thousands of points per second |

| Data Detail | Limited discrete points | High-density 3D point cloud |

| Equipment | Theodolites, total stations | 3D laser scanners, tripod systems |

| Post-Processing | Minimal, direct results | Requires software for point cloud processing |

| Cost | Lower initial investment | Higher equipment and training cost |

| Application Suitability | Small-scale projects, boundary surveys | Complex structures, large-scale projects |

Overview of Traditional Surveying Methods

Traditional surveying methods in construction primarily involve manual techniques such as using theodolites, total stations, and leveling instruments to measure angles, distances, and elevations. These methods rely on physical markers and line-of-sight observations to create accurate site layouts and topographic maps, with data recorded manually or via basic electronic devices. Despite being time-intensive and labor-heavy, traditional surveying remains fundamental for projects requiring established accuracy and familiarity within the industry.

Introduction to Laser Scanning Technology

Laser scanning technology revolutionizes construction surveying by capturing precise 3D measurements through rapid, non-contact data acquisition. Unlike traditional surveying, which relies on manual point measurements, laser scanners generate detailed point clouds that significantly enhance accuracy and efficiency in site analysis. This technology streamlines project workflows by providing comprehensive spatial data for design, planning, and quality control.

Key Differences Between Traditional Surveying and Laser Scanning

Traditional surveying relies on manual measurements using tools like total stations and theodolites, which can be time-consuming and prone to human error. Laser scanning employs LiDAR technology to rapidly capture detailed 3D spatial data with high accuracy and dense point clouds, enabling more precise modeling of complex structures. Key differences include processing speed, data resolution, and the ability to visualize environments in three dimensions, making laser scanning increasingly preferred in modern construction projects.

Accuracy and Precision: Comparing Both Approaches

Traditional surveying relies on manual measurements with instruments like theodolites and total stations, offering accuracy typically within a few millimeters but dependent on operator skill and environmental conditions. Laser scanning provides high-density point clouds with millimeter-level precision and consistently captures detailed 3D spatial data, reducing human error and improving repeatability. The enhanced accuracy and precision of laser scanning make it ideal for complex construction projects requiring comprehensive site documentation and quality control.

Speed and Efficiency in Data Collection

Traditional surveying methods rely on manual measurements and physical markers, resulting in slower data collection and increased potential for human error. Laser scanning technology captures millions of precise data points within seconds, significantly accelerating the surveying process while enhancing accuracy. This rapid data acquisition improves project timelines and reduces labor costs in construction site assessments.

Data Output Formats and Usability

Traditional surveying produces data formats such as total station coordinates and manual field notes, which require extensive processing and interpretation for CAD integration. Laser scanning generates dense point clouds in widely used formats like LAS, E57, and PLY, enabling direct import into BIM and 3D modeling software with high spatial accuracy. The usability of laser scanning data significantly enhances rapid decision-making and precision, while traditional surveying data involves slower workflows and potential human error in data transcription.

Cost Considerations in Surveying Projects

Traditional surveying methods typically involve lower initial equipment costs but require more labor hours, increasing overall project expenses. Laser scanning demands higher upfront investment in advanced technology but significantly reduces time spent on-site and enhances data accuracy, leading to cost savings in the long term. Budget allocation decisions in surveying projects must weigh immediate expenses against potential efficiency gains and quality improvements provided by laser scanning.

Field Application Scenarios in Construction

Traditional surveying remains essential for preliminary site layouts, topographic mapping, and boundary assessments, offering precise measurements for straightforward construction projects. Laser scanning excels in complex scenarios such as as-built documentation, clash detection, and detailed structural analysis, capturing millions of data points rapidly with high accuracy. Integrating both techniques enhances accuracy and efficiency across diverse construction phases, from initial surveys to precise monitoring of ongoing work.

Limitations and Challenges of Each Method

Traditional surveying faces limitations such as slower data collection, higher susceptibility to human error, and challenges in capturing complex geometries or large-scale sites efficiently. Laser scanning presents challenges like high initial equipment costs, extensive data processing requirements, and potential difficulties in capturing details in reflective or obstructed areas. Both methods require specialized expertise, but laser scanning demands advanced software skills to manage and interpret dense point cloud data effectively.

Future Trends in Surveying Technologies

Emerging trends in construction surveying emphasize a shift from traditional methods to advanced laser scanning technologies, enhancing accuracy and efficiency. Integration of 3D laser scanners with Building Information Modeling (BIM) allows real-time data capture and precise site mapping, significantly reducing human error and project delays. Future innovations focus on drone-assisted laser scanning, AI-powered data analysis, and cloud-based collaboration platforms to streamline workflows and improve decision-making on construction sites.

Related Important Terms

Point Cloud Alignment

Traditional surveying relies on manual measurements and physical markers to establish control points, which can lead to potential alignment errors between datasets. Laser scanning enhances point cloud alignment accuracy by capturing millions of precise spatial coordinates, enabling seamless integration with CAD models and improving construction project accuracy.

Terrestrial Laser Scanning (TLS)

Terrestrial Laser Scanning (TLS) offers high-precision 3D data capture, significantly reducing survey time compared to traditional surveying methods that rely on manual measurements and instrumentation. TLS enhances accuracy and efficiency in construction site mapping, enabling detailed as-built documentation and minimizing human error in complex structural assessments.

Scan-to-BIM

Traditional surveying relies on manual measurements and physical markers, often resulting in longer project timelines and potential for human error; laser scanning captures millions of high-precision data points rapidly, creating detailed 3D models ideal for accurate Scan-to-BIM workflows. The integration of laser scanning with Building Information Modeling (BIM) enhances clash detection, design accuracy, and project coordination, driving higher efficiency and cost savings in construction projects.

Reality Capture

Traditional surveying relies on manual measurements and tools such as total stations and GPS, offering limited data points and slower reality capture. Laser scanning uses LiDAR technology to rapidly generate dense 3D point clouds, providing highly accurate and comprehensive spatial data for detailed construction analysis and progress monitoring.

Georeferencing Accuracy

Traditional surveying provides georeferencing accuracy typically within a few centimeters, relying on manual measurements and ground control points, which can introduce human error. Laser scanning achieves millimeter-level georeferencing precision by capturing millions of data points and integrating advanced GPS and IMU technologies for enhanced spatial referencing.

Control Network Establishment

Traditional surveying for control network establishment relies on precise measurements using total stations and leveling instruments, offering high accuracy but requiring extensive manual labor and time. Laser scanning enhances control network setup by rapidly capturing dense 3D point clouds, improving spatial data integration and reducing the likelihood of human error during complex construction projects.

Digital Twin Modeling

Traditional surveying methods provide accurate point data but often lack the speed and density required for detailed digital twin modeling, whereas laser scanning captures millions of precise data points rapidly to create highly detailed 3D models. Digital twin models benefit from laser scanning's ability to generate comprehensive, real-time spatial data, enhancing virtual replication for construction planning, monitoring, and management.

Multi-Station Adjustment

Multi-Station Adjustment in traditional surveying involves manually aligning multiple instrument setups to minimize cumulative errors, often resulting in time-intensive workflows and potential human inaccuracies. Laser scanning automates this process by integrating point cloud data from various scan positions with high precision, significantly enhancing accuracy and efficiency in construction site measurements.

As-Built Verification

Traditional surveying relies on manual measurements and physical markers for as-built verification, which can be time-consuming and prone to human error. Laser scanning captures high-resolution, 3D point clouds of construction sites, enabling precise and efficient verification of as-built conditions against design models.

Topographic Meshing

Traditional surveying utilizes manual measurements and total stations for topographic meshing, providing accurate but time-consuming data collection, while laser scanning employs LiDAR technology to rapidly capture dense point clouds with higher spatial resolution and precision. Laser scanning enhances efficiency in creating detailed topographic meshes, enabling comprehensive terrain modeling and analysis in complex construction sites.

Traditional Surveying vs Laser Scanning Infographic

industrydif.com

industrydif.com