Drone surveying offers rapid aerial data collection with high-resolution imaging that enhances site mapping accuracy, while robotic site inspection provides detailed, close-up analysis of structural elements using autonomous ground-based devices. Drones excel in covering large areas quickly, capturing topographic and volumetric data essential for planning, whereas robots navigate confined spaces to detect defects, measure precise dimensions, and monitor safety conditions. Combining drone surveying and robotic site inspection optimizes construction site monitoring by integrating broad overviews with granular inspections for improved project management.

Table of Comparison

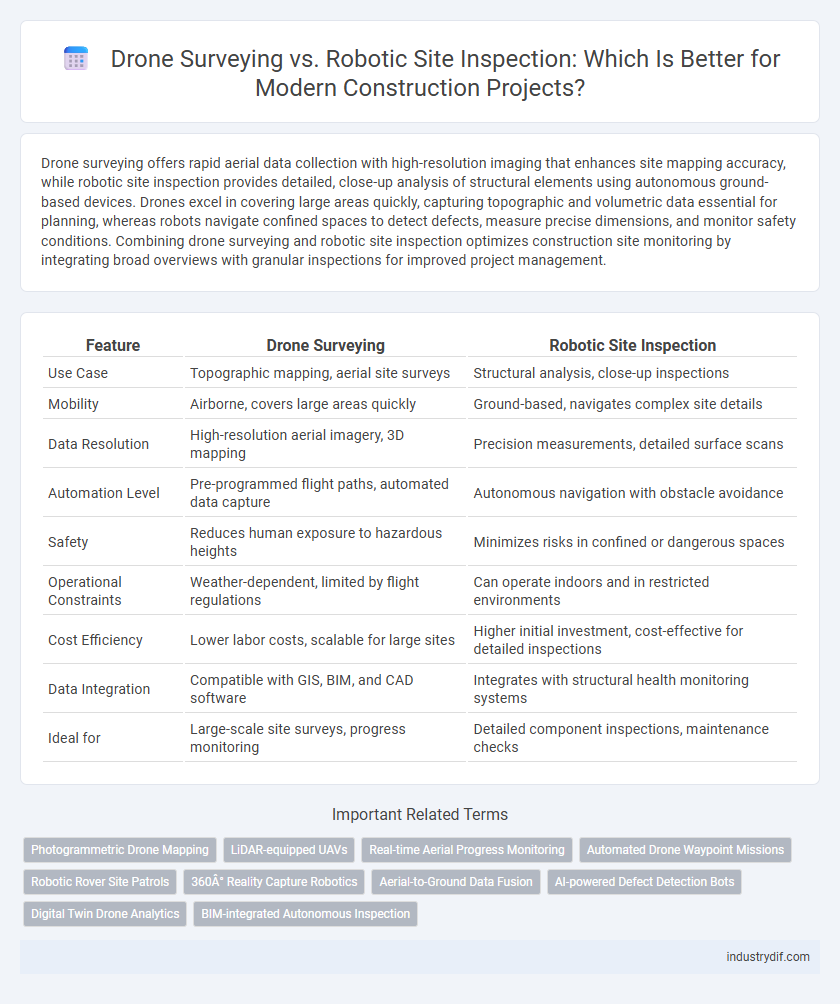

| Feature | Drone Surveying | Robotic Site Inspection |

|---|---|---|

| Use Case | Topographic mapping, aerial site surveys | Structural analysis, close-up inspections |

| Mobility | Airborne, covers large areas quickly | Ground-based, navigates complex site details |

| Data Resolution | High-resolution aerial imagery, 3D mapping | Precision measurements, detailed surface scans |

| Automation Level | Pre-programmed flight paths, automated data capture | Autonomous navigation with obstacle avoidance |

| Safety | Reduces human exposure to hazardous heights | Minimizes risks in confined or dangerous spaces |

| Operational Constraints | Weather-dependent, limited by flight regulations | Can operate indoors and in restricted environments |

| Cost Efficiency | Lower labor costs, scalable for large sites | Higher initial investment, cost-effective for detailed inspections |

| Data Integration | Compatible with GIS, BIM, and CAD software | Integrates with structural health monitoring systems |

| Ideal for | Large-scale site surveys, progress monitoring | Detailed component inspections, maintenance checks |

Overview of Drone Surveying in Construction

Drone surveying in construction utilizes unmanned aerial vehicles equipped with high-resolution cameras and LiDAR sensors to capture precise topographical data and site imagery. These surveys facilitate rapid, accurate mapping and volumetric measurements, reducing the need for manual labor and enhancing safety on complex or hazardous sites. Integration with BIM (Building Information Modeling) systems enables real-time data analysis for improved project planning and progress monitoring.

Fundamentals of Robotic Site Inspection

Robotic site inspection utilizes autonomous or semi-autonomous robots equipped with advanced sensors and imaging technology to conduct detailed assessments of construction sites, capturing high-resolution data for analysis. This method enhances precision in monitoring structural integrity, safety compliance, and progress tracking, outperforming traditional drone surveying by providing ground-level perspectives and accessing confined or hazardous areas. Integration with AI-powered data processing enables real-time decision-making and predictive maintenance, significantly improving construction efficiency and reducing human error.

Comparative Accuracy: Drones vs Robots

Drone surveying offers high-resolution aerial imagery with centimeter-level accuracy, ideal for large-scale topographic mapping and volume calculations. Robotic site inspection provides precise ground-level measurements using LIDAR and 3D scanning technology, ensuring sub-millimeter accuracy for detailed structural assessments. Comparing accuracy, drones excel in broad-area data collection, while robots outperform in granular detail and complex on-site inspections.

Data Collection Capabilities and Limitations

Drone surveying offers rapid aerial data collection with high-resolution imaging and 3D mapping, ideal for capturing large site overviews and hard-to-reach areas. Robotic site inspection excels in detailed ground-level analysis using sensors and cameras, providing precise measurements and real-time data on structural elements, but is limited by terrain obstacles and mobility constraints. Both methods complement construction site monitoring by balancing broad spatial coverage and targeted inspections, yet their effectiveness depends on the specific project requirements and environmental conditions.

Real-Time Monitoring and Reporting Efficiency

Drone surveying enhances real-time monitoring by capturing high-resolution aerial images and generating precise 3D maps, enabling rapid site assessment and instant data sharing. Robotic site inspection utilizes autonomous ground-based systems equipped with sensors to perform detailed environmental and structural analysis, providing continuous data streams for immediate reporting. Together, these technologies significantly improve reporting efficiency by reducing manual effort and enabling faster decision-making on construction sites.

Integration with BIM and Construction Software

Drone surveying offers high-resolution aerial data seamlessly integrated into BIM platforms, enabling real-time progress tracking and precise site mapping. Robotic site inspection complements this by delivering detailed ground-level measurements and automated quality checks directly linked to construction management software. Together, these technologies enhance the accuracy of as-built models and facilitate proactive decision-making throughout project lifecycles.

Safety Enhancements and Risk Management

Drone surveying offers elevated aerial perspectives that significantly reduce the need for workers to access hazardous or hard-to-reach areas, enhancing safety by minimizing exposure to potential onsite dangers. Robotic site inspections utilize autonomous ground-based machines equipped with sensors to continuously monitor environmental conditions and structural integrity, enabling early detection of risks and proactive management. Integrating both technologies optimizes risk mitigation strategies in construction projects by combining comprehensive data collection with reduced human intervention in dangerous zones.

Cost Analysis: Implementation and Operation

Drone surveying offers a lower initial investment with reduced labor costs and faster data collection compared to robotic site inspection, which requires higher upfront expenses for advanced robotics and maintenance. Operational costs for drone surveying remain minimal due to ease of deployment and fewer technical issues, while robotic inspections incur ongoing costs from specialized operators and complex system repairs. Evaluating cost efficiency depends on project scale and required precision, where drones excel in large-area surveys and robots provide detailed inspections for high-risk environments.

Regulatory Compliance and Airspace Considerations

Drone surveying in construction requires strict adherence to aviation regulations such as FAA Part 107 in the U.S. and EASA standards in Europe, ensuring operators possess certifications and comply with flight restrictions including no-fly zones and altitude limits. Robotic site inspection operates on the ground, minimizing airspace regulatory challenges but must comply with occupational safety standards and site-specific operational permits. Selecting between drone surveying and robotic site inspection depends on balancing airspace regulatory complexities with the need for precise, real-time data collection on construction sites.

Future Trends in Automated Construction Technologies

Drone surveying and robotic site inspection represent the forefront of automated construction technologies, integrating AI-driven data analysis and real-time monitoring to enhance precision and efficiency. Advanced drones equipped with high-resolution LiDAR sensors and multispectral cameras enable rapid topographic mapping and progress tracking, while robotic inspectors utilize AI-powered vision systems for detailed structural assessment and hazard detection. Future trends emphasize the convergence of these technologies with IoT platforms and 5G connectivity, driving smarter, safer, and more cost-effective site management.

Related Important Terms

Photogrammetric Drone Mapping

Photogrammetric drone mapping provides high-resolution, georeferenced aerial images that enable precise topographic surveys and volumetric calculations, significantly enhancing site analysis accuracy and efficiency. Robotic site inspection complements this by automating ground-level data collection, but drone surveys excel in quickly covering large areas and generating detailed 3D models for construction planning and monitoring.

LiDAR-equipped UAVs

LiDAR-equipped UAVs in drone surveying deliver high-resolution topographic data, enabling rapid terrain mapping and volumetric analysis essential for construction planning. Robotic site inspection relies on ground-based LiDAR sensors for detailed structural assessment, offering precision in confined spaces but with slower deployment compared to aerial UAV surveys.

Real-time Aerial Progress Monitoring

Drone surveying provides real-time aerial progress monitoring by capturing high-resolution images and generating up-to-date 3D models, enabling precise tracking of construction site developments from above. Robotic site inspection, while highly accurate in close-range assessments, lacks the wide-area coverage and immediate visual updates that drones offer for comprehensive progress analysis.

Automated Drone Waypoint Missions

Automated drone waypoint missions enable precise, repeatable data collection across construction sites by programming drones to follow predefined GPS coordinates, enhancing accuracy and efficiency in surveying tasks. In contrast, robotic site inspections rely on ground-based systems that navigate autonomously but face limitations in accessing elevated or hazardous areas, making drone surveying the preferred method for comprehensive aerial site analysis.

Robotic Rover Site Patrols

Robotic rover site patrols offer continuous, autonomous monitoring of construction sites, capturing high-resolution data and real-time environmental conditions to enhance safety and progress tracking. Compared to drone surveying, robotic rovers provide stable ground-level inspections that excel in complex terrains and confined areas, reducing human risk and improving data accuracy for site management.

360° Reality Capture Robotics

360deg reality capture robotics in construction provides highly detailed, accurate site data by using integrated sensors and cameras to generate comprehensive, immersive visualizations, enhancing progress monitoring and quality control. Compared to drone surveying, robotic site inspection offers superior stability and close-proximity data acquisition in complex environments, improving safety and enabling precise as-built documentation for project management.

Aerial-to-Ground Data Fusion

Drone surveying captures high-resolution aerial imagery and topographic data, while robotic site inspection collects precise ground-level measurements; integrating these datasets through aerial-to-ground data fusion enhances construction site analysis by providing comprehensive, real-time spatial information. This fusion enables accurate 3D modeling, improves monitoring of site progress, and optimizes decision-making for project management and quality control.

AI-powered Defect Detection Bots

AI-powered defect detection bots in drone surveying provide high-resolution aerial data for identifying structural issues across expansive construction sites, enhancing accuracy in capturing surface anomalies and elevation changes. Robotic site inspection bots utilize advanced sensors and AI algorithms for detailed, ground-level analysis of hard-to-reach areas, enabling real-time, automated defect recognition and maintenance scheduling.

Digital Twin Drone Analytics

Digital twin drone analytics in construction leverages high-resolution aerial data to create precise 3D models, enhancing real-time monitoring and predictive maintenance compared to traditional robotic site inspections. This technology enables comprehensive site analysis, reducing human error and improving project efficiency by integrating geospatial data with material tracking for accurate digital twin updates.

BIM-integrated Autonomous Inspection

BIM-integrated autonomous inspection enhances construction site accuracy by combining drone surveying's aerial data capture with robotic site inspection's precise ground-level analysis, enabling real-time 3D modeling updates and reducing human error. This integration streamlines project workflows, improves safety, and accelerates progress tracking through continuous, automated monitoring aligned with Building Information Modeling standards.

Drone Surveying vs Robotic Site Inspection Infographic

industrydif.com

industrydif.com