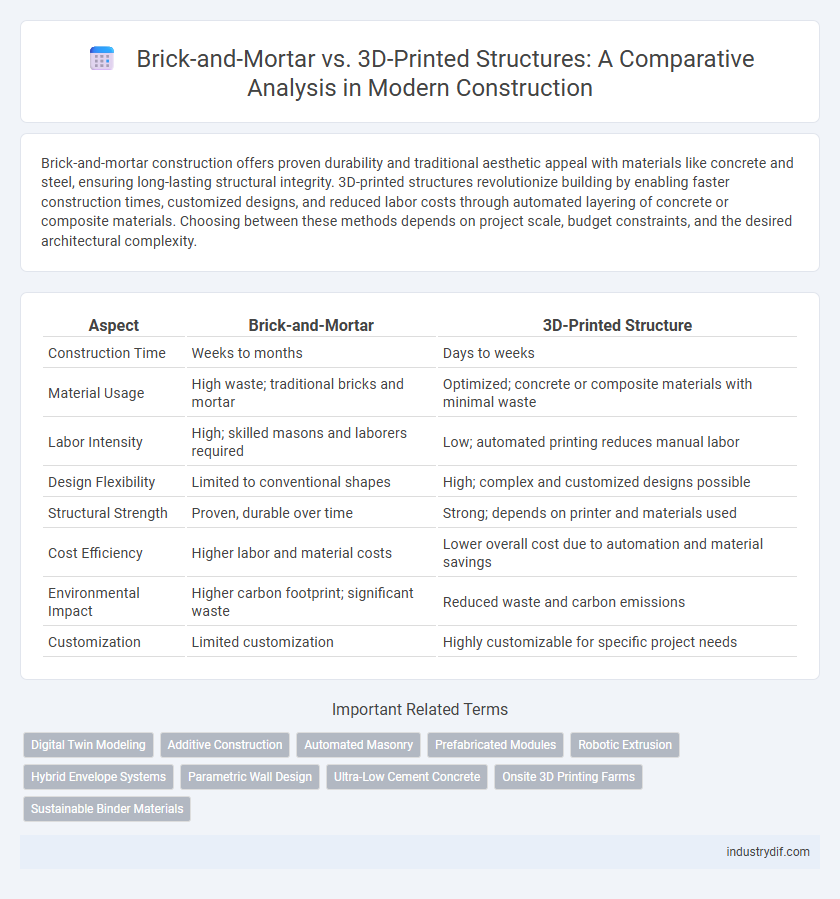

Brick-and-mortar construction offers proven durability and traditional aesthetic appeal with materials like concrete and steel, ensuring long-lasting structural integrity. 3D-printed structures revolutionize building by enabling faster construction times, customized designs, and reduced labor costs through automated layering of concrete or composite materials. Choosing between these methods depends on project scale, budget constraints, and the desired architectural complexity.

Table of Comparison

| Aspect | Brick-and-Mortar | 3D-Printed Structure |

|---|---|---|

| Construction Time | Weeks to months | Days to weeks |

| Material Usage | High waste; traditional bricks and mortar | Optimized; concrete or composite materials with minimal waste |

| Labor Intensity | High; skilled masons and laborers required | Low; automated printing reduces manual labor |

| Design Flexibility | Limited to conventional shapes | High; complex and customized designs possible |

| Structural Strength | Proven, durable over time | Strong; depends on printer and materials used |

| Cost Efficiency | Higher labor and material costs | Lower overall cost due to automation and material savings |

| Environmental Impact | Higher carbon footprint; significant waste | Reduced waste and carbon emissions |

| Customization | Limited customization | Highly customizable for specific project needs |

Introduction: Evolution of Construction Methods

Traditional brick-and-mortar construction has dominated the industry for centuries, offering durability and time-tested techniques for building residential and commercial structures. The advent of 3D-printed construction introduces digital fabrication technology that allows for rapid, cost-effective, and customizable building processes. Emerging 3D printing methods leverage advanced materials and automation, reshaping the future landscape of construction by reducing waste and enhancing design flexibility.

Brick-and-Mortar: Traditional Construction Overview

Brick-and-mortar construction relies on conventional materials such as clay bricks, cement mortar, and steel reinforcements, providing proven durability and structural integrity for residential and commercial buildings. This method benefits from well-established techniques, extensive labor expertise, and compliance with building codes, ensuring reliable load-bearing capabilities and long-term stability. Despite longer construction times and higher labor costs compared to 3D printing, brick-and-mortar remains the dominant approach due to its adaptability in diverse architectural designs and proven performance in various environmental conditions.

3D Printing: Disruptive Technology in Building

3D printing revolutionizes construction by enabling rapid fabrication of complex, customized building components with significantly reduced labor costs and material waste compared to traditional brick-and-mortar methods. Advanced additive manufacturing techniques allow for on-site construction of durable, energy-efficient structures using innovative materials like geopolymer concrete and recycled composites. This disruptive technology accelerates project timelines, enhances design flexibility, and supports sustainable building practices worldwide.

Materials Used: Conventional vs. Additive Manufacturing

Traditional brick-and-mortar construction primarily utilizes materials such as clay bricks, concrete blocks, mortar, and steel reinforcements, which offer proven durability and structural integrity. In contrast, 3D-printed structures rely on additive manufacturing techniques using specialized concrete mixtures, polymer composites, and sometimes recycled materials that allow for precise layering and reduced material waste. The shift from conventional to additive materials highlights innovations in sustainability, customization, and construction speed while maintaining performance standards.

Speed and Efficiency: Project Timelines Compared

Brick-and-mortar construction typically involves longer project timelines due to material curing and manual labor constraints, often taking several months to complete. In contrast, 3D-printed structures can reduce building time by up to 50-70%, as automated layering processes and fewer material dependencies accelerate progress. This efficiency in 3D printing leads to faster project delivery, significantly benefiting time-sensitive construction developments.

Cost Analysis: Budget Implications for Each Method

Brick-and-mortar construction typically involves higher labor and material costs, with expenses influenced by skilled workforce wages and traditional supply chains. 3D-printed structures offer significant cost savings through reduced labor requirements and minimal material waste, lowering overall budget demands. However, initial investment in advanced printing technology and design software can impact upfront costs, making a detailed cost-benefit analysis essential for project viability.

Structural Integrity and Durability

Brick-and-mortar construction offers proven structural integrity and durability through time-tested materials like fired clay bricks and mortar, providing strong resistance to weathering and load-bearing capacity. In contrast, 3D-printed structures utilize advanced materials such as concrete mixes with additives that enhance tensile strength and reduce curing time, enabling rapid construction while maintaining robustness. Ongoing innovations in 3D printing technology aim to match or exceed traditional brick-and-mortar durability by improving layer adhesion and incorporating reinforcement techniques.

Sustainability and Environmental Impact

Brick-and-mortar construction typically generates higher carbon emissions due to the extensive use of cement and traditional materials, while 3D-printed structures utilize eco-friendly, recyclable composites that significantly reduce waste. 3D printing enables precise material application, minimizing excess usage and construction debris, thus promoting sustainable resource management. Lifecycle assessments reveal that 3D-printed buildings have a lower environmental footprint, contributing to energy efficiency and reduced greenhouse gas emissions over time.

Design Flexibility and Customization

Brick-and-mortar construction offers limited design flexibility due to standardized shapes and labor-intensive customization processes. In contrast, 3D-printed structures enable complex geometries and personalized architectural features through digital modeling, reducing material waste and construction time. Advanced 3D printing technology supports adaptive designs tailored to specific structural and aesthetic requirements, surpassing traditional methods in customization capabilities.

Future Trends: Adoption and Industry Outlook

The construction industry is rapidly shifting towards 3D-printed structures due to advancements in additive manufacturing technology, offering faster build times and reduced material waste compared to traditional brick-and-mortar methods. Market forecasts predict a compound annual growth rate (CAGR) exceeding 20% for 3D printing in construction through 2030, driven by increased demand for sustainable and cost-effective building solutions. Leading construction firms and governments are investing heavily in research and pilot projects, signaling widespread adoption and integration of 3D printing as a mainstream building practice in the near future.

Related Important Terms

Digital Twin Modeling

Digital Twin Modeling significantly enhances 3D-printed structures by enabling real-time monitoring, predictive maintenance, and precise virtual simulations, which traditional brick-and-mortar construction lacks. This integration reduces errors, accelerates project timelines, and optimizes resource management, transforming the efficiency and sustainability of the construction process.

Additive Construction

Additive construction through 3D printing revolutionizes traditional brick-and-mortar methods by enabling rapid, precise layering of concrete and composite materials, reducing labor costs and material waste significantly. This technology enhances design flexibility and structural complexity that conventional masonry struggles to achieve, promoting sustainable and efficient building practices.

Automated Masonry

Automated masonry in 3D-printed structures significantly reduces labor costs and construction time compared to traditional brick-and-mortar methods by using robotic arms and computer-controlled processes to precisely place materials layer by layer. This technology enhances structural accuracy and minimizes material waste, offering scalable solutions for complex architectural designs and sustainable building practices.

Prefabricated Modules

Prefabricated modules in brick-and-mortar construction offer standardized quality and faster assembly times, reducing on-site labor and waste. 3D-printed structures leverage advanced robotics to create intricate, custom designs with minimal material usage, promoting sustainability and reducing overall construction costs.

Robotic Extrusion

Robotic extrusion in 3D-printed construction enables precise layering of concrete or composite materials, reducing waste and labor costs compared to traditional brick-and-mortar methods. This technology accelerates build times and allows for complex, custom structural designs that are challenging to achieve with conventional masonry.

Hybrid Envelope Systems

Hybrid envelope systems in construction combine traditional brick-and-mortar techniques with 3D-printed structural components to enhance thermal insulation, durability, and design flexibility. Integrating these methods optimizes energy efficiency and reduces material waste while maintaining the aesthetic appeal and strength of conventional masonry.

Parametric Wall Design

Parametric wall design in brick-and-mortar construction allows precise customization of structural elements, optimizing material use and enhancing aesthetic flexibility. In 3D-printed structures, parametric design integrates digital fabrication techniques to produce complex geometries with reduced waste and faster construction timelines.

Ultra-Low Cement Concrete

Ultra-low cement concrete in brick-and-mortar construction offers traditional durability with reduced carbon emissions, while 3D-printed structures utilizing this material enable precise layering and faster build times with minimal waste. The integration of ultra-low cement concrete in 3D printing technology enhances sustainability and structural efficiency compared to conventional methods.

Onsite 3D Printing Farms

Onsite 3D printing farms revolutionize construction by enabling rapid, customizable brick-and-mortar structures with reduced labor costs and material waste. These farms enhance project scalability and precision, outperforming traditional construction methods in speed and sustainability.

Sustainable Binder Materials

Sustainable binder materials in brick-and-mortar construction often rely on traditional cement, which has a high carbon footprint, whereas 3D-printed structures utilize innovative binders like geopolymer and bio-based composites that significantly reduce greenhouse gas emissions. Advances in eco-friendly binders for 3D printing support energy efficiency and material recyclability, promoting greener building practices and minimizing environmental impact.

Brick-and-Mortar vs 3D-Printed Structure Infographic

industrydif.com

industrydif.com