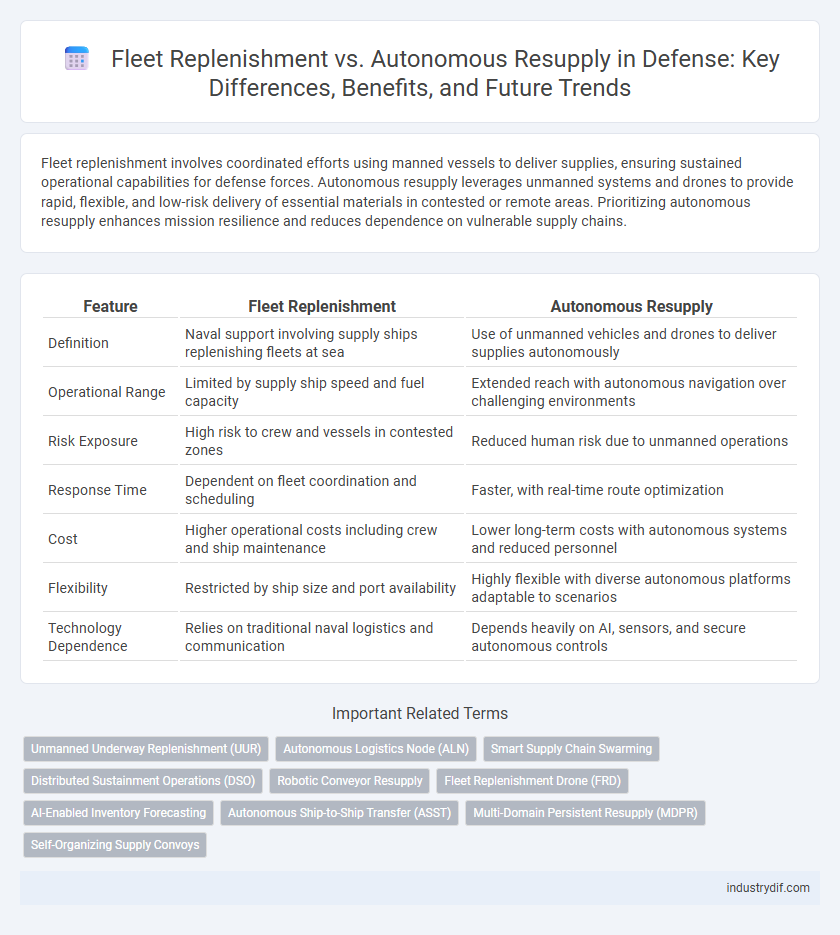

Fleet replenishment involves coordinated efforts using manned vessels to deliver supplies, ensuring sustained operational capabilities for defense forces. Autonomous resupply leverages unmanned systems and drones to provide rapid, flexible, and low-risk delivery of essential materials in contested or remote areas. Prioritizing autonomous resupply enhances mission resilience and reduces dependence on vulnerable supply chains.

Table of Comparison

| Feature | Fleet Replenishment | Autonomous Resupply |

|---|---|---|

| Definition | Naval support involving supply ships replenishing fleets at sea | Use of unmanned vehicles and drones to deliver supplies autonomously |

| Operational Range | Limited by supply ship speed and fuel capacity | Extended reach with autonomous navigation over challenging environments |

| Risk Exposure | High risk to crew and vessels in contested zones | Reduced human risk due to unmanned operations |

| Response Time | Dependent on fleet coordination and scheduling | Faster, with real-time route optimization |

| Cost | Higher operational costs including crew and ship maintenance | Lower long-term costs with autonomous systems and reduced personnel |

| Flexibility | Restricted by ship size and port availability | Highly flexible with diverse autonomous platforms adaptable to scenarios |

| Technology Dependence | Relies on traditional naval logistics and communication | Depends heavily on AI, sensors, and secure autonomous controls |

Introduction to Fleet Replenishment and Autonomous Resupply

Fleet replenishment involves the traditional method of supplying naval vessels with fuel, ammunition, and provisions while at sea, ensuring continuous operational capability without returning to port. Autonomous resupply utilizes unmanned systems such as drones and autonomous vessels to deliver supplies, reducing risk to personnel and increasing logistic efficiency in contested or remote environments. These evolving technologies are critical in modern defense strategies to maintain sustained maritime presence and operational readiness.

Historical Evolution of Fleet Replenishment

Fleet replenishment has evolved from manual over-the-side transfers during World War II to sophisticated underway replenishment techniques enabling continuous naval operations without port visits. Innovations in replenishment oilers and supply ships integrated advanced transfer rigs and helicopters to increase speed and safety, reducing vulnerability during resupply missions. This historical progression laid the groundwork for autonomous resupply technologies, expanding operational range and reducing human risk in modern naval logistics.

Core Principles of Autonomous Resupply Operations

Core principles of autonomous resupply operations emphasize real-time situational awareness, seamless integration of unmanned systems, and adaptive logistics planning to support dynamic fleet requirements. These principles ensure continuous, precise delivery of supplies without human intervention, reducing risk and operational downtime. Autonomous resupply enhances fleet endurance by leveraging AI-driven navigation, automated load management, and secure communication networks.

Key Technologies Enabling Modern Resupply Methods

Fleet replenishment relies on advanced underway replenishment systems featuring high-capacity fuel lines, automated cargo transfer mechanisms, and ship-to-ship communication protocols that ensure seamless coordination during operations. Autonomous resupply utilizes cutting-edge technologies such as AI-driven navigation, autonomous surface and underwater vehicles, and real-time data analytics to perform resupply missions with minimal human intervention. Both methods are enabled by innovations in secure satellite communication, IoT sensor integration, and machine learning algorithms that enhance efficiency, accuracy, and operational safety in maritime logistics.

Comparative Advantages: Manned vs. Unmanned Systems

Manned fleet replenishment systems offer robust operational flexibility and immediate human decision-making capabilities essential for complex logistics in contested environments. Autonomous resupply systems provide enhanced stealth, reduced risk to personnel, and cost efficiency through extended endurance and lower operational demands. The comparative advantage lies in integrating both approaches to leverage human judgment alongside autonomous precision, optimizing mission effectiveness and resilience in naval operations.

Operational Efficiency and Mission Readiness

Fleet replenishment enhances operational efficiency by allowing continuous support of naval vessels through underway logistics, reducing downtime and maintaining mission readiness. Autonomous resupply platforms leverage advanced robotics and AI to deliver supplies with minimal human intervention, increasing speed and precision in complex environments. Integrating autonomous resupply with traditional fleet replenishment optimizes resource allocation, ensuring sustained operational capability and rapid response in defense missions.

Cost Analysis and Resource Allocation

Fleet replenishment operations demand significant logistical coordination and fuel expenditures, often involving multiple support vessels to sustain prolonged missions, which escalates operational costs. Autonomous resupply systems reduce manpower requirements and enable precision delivery, optimizing resource allocation by minimizing fuel consumption and vessel deployment. Cost analysis reveals autonomous technology investments can lower long-term expenditures through decreased personnel costs and enhanced efficiency in supply chains within naval defense operations.

Challenges and Limitations in Field Deployment

Fleet replenishment faces logistical challenges such as dependency on supply ships vulnerable to enemy attacks and limited sea state conditions restricting operational windows. Autonomous resupply systems encounter technological limitations including unreliable navigation in contested environments and insufficient payload capacity for critical supplies. Both approaches struggle with integration into existing naval operations due to cybersecurity risks and interoperability issues with legacy platforms.

Future Trends in Defensive Logistics

Future trends in defensive logistics emphasize the integration of autonomous resupply systems to enhance fleet replenishment efficiency. Autonomous vessels equipped with advanced AI and sensors reduce human risk and improve precision in delivering fuel, ammunition, and supplies at sea. This shift supports continuous operational readiness and rapid response in contested maritime environments.

Strategic Implications for Military Sustainment

Fleet replenishment enhances operational reach by enabling sustained maritime presence through underway resupply of fuel, munitions, and provisions, reducing dependence on fixed bases. Autonomous resupply platforms offer strategic advantages in contested environments by minimizing personnel risk and increasing supply chain resilience via unmanned logistics. Integrating autonomous systems with traditional fleet replenishment optimizes force projection and sustainment agility in dynamic threat landscapes.

Related Important Terms

Unmanned Underway Replenishment (UUR)

Unmanned Underway Replenishment (UUR) significantly enhances fleet replenishment by enabling autonomous resupply operations at sea, reducing dependency on manned vessels and minimizing human risk. UUR systems leverage advanced robotics and AI to efficiently transfer fuel, munitions, and supplies between ships, ensuring sustained naval operations with increased operational flexibility and lowered logistical footprints.

Autonomous Logistics Node (ALN)

Autonomous Logistics Nodes (ALNs) enhance fleet replenishment by enabling self-sustained, automated resupply operations with reduced human intervention, increasing operational efficiency and resilience in contested environments. These nodes integrate advanced robotics, AI-driven logistics management, and real-time data analytics to optimize supply chain flow, minimizing the downtime and risk associated with traditional fleet support methods.

Smart Supply Chain Swarming

Fleet replenishment leverages coordinated logistics vessels to deliver fuel, ammunition, and provisions, ensuring sustained operational readiness across vast maritime theaters. Autonomous resupply employs AI-powered drones and autonomous ships executing smart supply chain swarming, optimizing route efficiency and reducing human risk through synchronized, real-time inventory distribution.

Distributed Sustainment Operations (DSO)

Fleet Replenishment enables continuous naval operations by delivering supplies directly to deployed vessels, enhancing operational reach and force projection within Distributed Sustainment Operations (DSO). Autonomous Resupply leverages unmanned platforms to increase resupply efficiency and reduce risk to personnel, supporting DSO by ensuring timely, flexible logistics in contested maritime environments.

Robotic Conveyor Resupply

Robotic conveyor resupply enhances fleet replenishment by enabling continuous, automated transfer of supplies between vessels, reducing human risk and increasing operational tempo. Integrating robotic conveyor systems in autonomous resupply platforms optimizes logistics efficiency, minimizes downtime, and supports sustained maritime force projection.

Fleet Replenishment Drone (FRD)

Fleet Replenishment Drones (FRDs) enhance naval logistics by delivering fuel, ammunition, and supplies directly to ships at sea, reducing dependency on manned replenishment vessels and increasing operational tempo. These autonomous systems leverage advanced navigation and sensor technologies to perform precise rendezvous and transfer, optimizing fleet sustainment while minimizing risks to personnel.

AI-Enabled Inventory Forecasting

AI-enabled inventory forecasting enhances fleet replenishment by predicting supply needs with high accuracy, reducing delays and minimizing stockouts during naval operations. Autonomous resupply systems integrated with real-time AI analytics optimize inventory levels on demand, ensuring sustained mission readiness and efficient resource utilization.

Autonomous Ship-to-Ship Transfer (ASST)

Autonomous Ship-to-Ship Transfer (ASST) revolutionizes fleet replenishment by enabling unmanned vessels to conduct precise, real-time resupply operations at sea, reducing human risk and increasing operational efficiency. Integrating advanced AI navigation, sensor fusion, and automated handling systems, ASST enhances sustained maritime endurance and minimizes logistical delays in dynamic naval environments.

Multi-Domain Persistent Resupply (MDPR)

Fleet Replenishment ensures continuous operational readiness by coordinating traditional supply vessels with aerial and surface assets, while Autonomous Resupply leverages unmanned systems to deliver supplies across contested environments. Multi-Domain Persistent Resupply (MDPR) integrates these approaches, employing AI-driven autonomous platforms and synergized logistics networks to sustain multi-theater force projection with reduced human risk and enhanced supply chain resilience.

Self-Organizing Supply Convoys

Self-organizing supply convoys leverage autonomous systems and artificial intelligence to enhance fleet replenishment by optimizing route efficiency and reducing human risk in contested environments. These convoys enable real-time adaptive logistics, ensuring timely delivery of munitions, fuel, and provisions while maintaining operational security and minimizing supply chain vulnerabilities.

Fleet Replenishment vs Autonomous Resupply Infographic

industrydif.com

industrydif.com