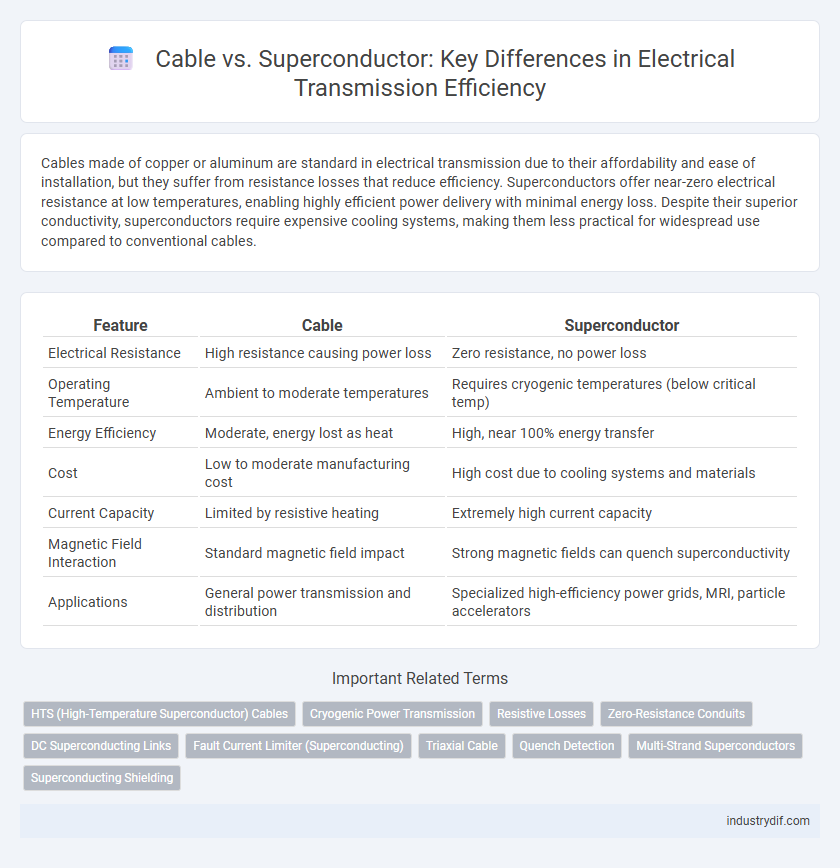

Cables made of copper or aluminum are standard in electrical transmission due to their affordability and ease of installation, but they suffer from resistance losses that reduce efficiency. Superconductors offer near-zero electrical resistance at low temperatures, enabling highly efficient power delivery with minimal energy loss. Despite their superior conductivity, superconductors require expensive cooling systems, making them less practical for widespread use compared to conventional cables.

Table of Comparison

| Feature | Cable | Superconductor |

|---|---|---|

| Electrical Resistance | High resistance causing power loss | Zero resistance, no power loss |

| Operating Temperature | Ambient to moderate temperatures | Requires cryogenic temperatures (below critical temp) |

| Energy Efficiency | Moderate, energy lost as heat | High, near 100% energy transfer |

| Cost | Low to moderate manufacturing cost | High cost due to cooling systems and materials |

| Current Capacity | Limited by resistive heating | Extremely high current capacity |

| Magnetic Field Interaction | Standard magnetic field impact | Strong magnetic fields can quench superconductivity |

| Applications | General power transmission and distribution | Specialized high-efficiency power grids, MRI, particle accelerators |

Introduction to Cable and Superconductor Technologies

Traditional electrical cables typically use copper or aluminum conductors to transmit electricity, offering reliable performance with moderate energy losses due to resistance. Superconductor technologies employ materials that exhibit zero electrical resistance at cryogenic temperatures, enabling highly efficient power transmission with minimal energy dissipation. Emerging applications of superconductors include power grids, magnetic resonance imaging (MRI), and maglev trains, where enhanced conductivity and reduced heat generation provide significant operational advantages.

Fundamental Differences: Cable vs Superconductor

Traditional cables rely on conductive materials like copper or aluminum, which exhibit electrical resistance causing energy loss as heat during current flow. Superconductors, in contrast, allow electric current to pass without resistance when cooled below their critical temperature, enabling highly efficient energy transmission. The fundamental difference lies in the zero-resistance property of superconductors, which is unattainable in conventional cables, leading to significant improvements in power capacity and loss reduction.

Electrical Conductivity: Standard Cables vs Superconductors

Standard electrical cables typically exhibit resistivity that causes energy loss through heat dissipation, limiting their efficiency in high-current or long-distance applications. Superconductors, by contrast, demonstrate zero electrical resistance below their critical temperature, enabling lossless current flow and unprecedented conductivity. This fundamental difference in electrical conductivity makes superconductors highly advantageous for power transmission and magnetic applications.

Power Transmission Efficiency Comparison

Superconductors offer near-zero electrical resistance, enabling power transmission with losses less than 1%, compared to conventional cables that typically lose 5-10% due to resistance and heat dissipation. The critical temperature and material composition of superconductors, such as high-temperature YBCO tapes, significantly reduce cooling costs, enhancing overall efficiency in grids. Conventional copper or aluminum cables require larger cross-sections to minimize losses, while superconducting cables maintain high capacity in compact designs, optimizing space and efficiency in power transmission systems.

Material Composition and Engineering

Traditional cables are typically made from copper or aluminum, chosen for their high electrical conductivity and mechanical flexibility, yet they suffer from resistive losses due to inherent material resistance. Superconductors, composed of complex ceramic compounds like yttrium barium copper oxide (YBCO) or niobium-titanium alloys, enable zero electrical resistance below critical temperatures, revolutionizing efficiency in high-capacity energy transmission. Engineering superconducting cables demands meticulous cryogenic cooling systems and specialized insulation to maintain superconductivity, contrasting with the simpler, ambient temperature operation of conventional cables.

Installation and Maintenance Challenges

Cable installation involves managing weight, flexibility, and insulation requirements while ensuring compatibility with existing infrastructure, which can complicate routing and increase labor time. Superconductor systems require cryogenic cooling infrastructure to maintain low temperatures, leading to specialized equipment needs and complex thermal insulation challenges. Maintenance for superconductors often demands careful monitoring of cooling systems and advanced diagnostic tools, whereas conventional cables typically involve routine inspections and straightforward repair protocols.

Operational Costs and Energy Losses

Superconductors offer significantly lower operational costs compared to traditional cables due to near-zero electrical resistance, which drastically reduces energy losses during transmission. Conventional cables experience higher resistance, leading to substantial energy dissipation as heat and increased cooling expenses. The enhanced efficiency of superconductors results in lower power consumption and maintenance costs, making them a cost-effective solution for large-scale electricity distribution.

Scalability for Grid Applications

Superconductors offer superior scalability for grid applications due to their negligible electrical resistance, enabling high-capacity power transmission with minimal energy loss over long distances. In contrast, conventional cables face limitations in scalability caused by resistive heating and material constraints, requiring thicker conductors and complex cooling systems to handle increased loads. The critical challenge for superconductors lies in maintaining cryogenic conditions, which impacts the practicality and cost-efficiency of large-scale grid integration.

Safety and Reliability Considerations

Superconductors offer significantly higher reliability in electrical transmission due to zero electrical resistance, minimizing energy losses and reducing the risk of overheating compared to traditional cables. Safety considerations favor superconductors as they operate at lower temperatures and can be designed to automatically shut down during faults, unlike conventional cables which may pose fire hazards from overheating or insulation failure. However, the critical need for cryogenic cooling systems in superconductors introduces complexity and potential points of failure, requiring rigorous maintenance protocols to ensure consistent operational safety.

Future Trends: The Evolving Role of Superconductors in Electricity

Superconductors are poised to revolutionize electricity transmission by enabling near-zero resistance power lines, drastically reducing energy loss compared to traditional copper or aluminum cables. Future trends indicate increased integration of high-temperature superconducting materials in grid infrastructure, enhancing efficiency and capacity while supporting renewable energy expansion. Research advancements and cost reductions in superconductor manufacturing promise widespread adoption, positioning superconductors as a critical technology for sustainable and resilient power systems.

Related Important Terms

HTS (High-Temperature Superconductor) Cables

HTS (High-Temperature Superconductor) cables offer significantly lower electrical resistance compared to conventional copper or aluminum cables, enabling higher current capacity and improved energy efficiency in power transmission. These cables operate at elevated cryogenic temperatures, reducing cooling costs and enhancing grid reliability while minimizing power losses and environmental impact.

Cryogenic Power Transmission

Cryogenic power transmission using superconductors offers significantly lower resistive losses compared to conventional copper or aluminum cables, enhancing energy efficiency and capacity in electricity grids. Superconducting cables operate at extremely low temperatures to achieve zero electrical resistance, enabling higher current densities and reduced thermal dissipation in power delivery systems.

Resistive Losses

Copper and aluminum cables experience significant resistive losses due to their inherent electrical resistance, resulting in energy dissipation as heat during transmission. Superconductors, with zero electrical resistance below critical temperatures, eliminate these resistive losses, enabling highly efficient electricity transfer and reducing energy waste in power grids.

Zero-Resistance Conduits

Superconductors provide zero-resistance conduits for electrical current, eliminating energy losses common in traditional copper or aluminum cables, which typically face resistance-related heat dissipation. This fundamental difference enables superconducting cables to transmit electricity more efficiently over long distances, significantly reducing operational costs and improving grid stability.

DC Superconducting Links

Direct current (DC) superconducting links offer significantly lower energy losses compared to conventional copper or aluminum cables by enabling near-zero resistance transmission over long distances. These superconducting cables, often cooled with liquid nitrogen, provide higher current capacity and improved grid stability, making them ideal for efficient, high-capacity power delivery in urban and renewable energy integration projects.

Fault Current Limiter (Superconducting)

Superconducting Fault Current Limiters (SFCLs) offer rapid response and significantly lower resistance during normal operation compared to traditional cable-based limiters, effectively limiting fault currents without disrupting power flow. Their zero-resistance state ensures minimal energy loss, enhances grid stability, and mitigates equipment damage during electrical faults.

Triaxial Cable

Triaxial cables, featuring an inner conductor surrounded by two insulating layers and two concentric conductors, provide enhanced shielding and reduced electromagnetic interference compared to traditional coaxial cables, making them ideal for precise electrical measurements and high-frequency applications. Unlike superconductors that offer zero resistance only at cryogenic temperatures, triaxial cables maintain reliable conductivity and durability at standard operating conditions without the complexity of cooling systems.

Quench Detection

Quench detection in superconductors is critical as it prevents damage by rapidly identifying the transition from superconducting to resistive state, unlike traditional cables that consistently conduct without such abrupt phase changes. Advanced sensors and monitoring techniques enable early quench detection in superconducting systems, ensuring reliability and safety in high-power electrical applications.

Multi-Strand Superconductors

Multi-strand superconductors offer significantly higher current-carrying capacity and reduced energy losses compared to traditional copper or aluminum cables due to their zero-resistance properties at cryogenic temperatures. These superconducting cables enhance grid efficiency and reliability, enabling compact designs that support greater power density for advanced electrical transmission systems.

Superconducting Shielding

Superconducting shielding offers unparalleled magnetic field attenuation due to the Meissner effect, eliminating electromagnetic interference in highly sensitive electrical systems. Unlike traditional cables, superconductors provide zero electrical resistance and maintain field exclusion even under strong currents, enhancing energy efficiency and device performance.

Cable vs Superconductor Infographic

industrydif.com

industrydif.com