Master Data Management (MDM) ensures consistency and accuracy of core business data across an organization, serving as the single source of truth. Digital Twin technology creates a virtual representation of physical assets or processes, enabling real-time simulation and analysis. While MDM focuses on data governance and integration, Digital Twins emphasize dynamic modeling and operational insights.

Table of Comparison

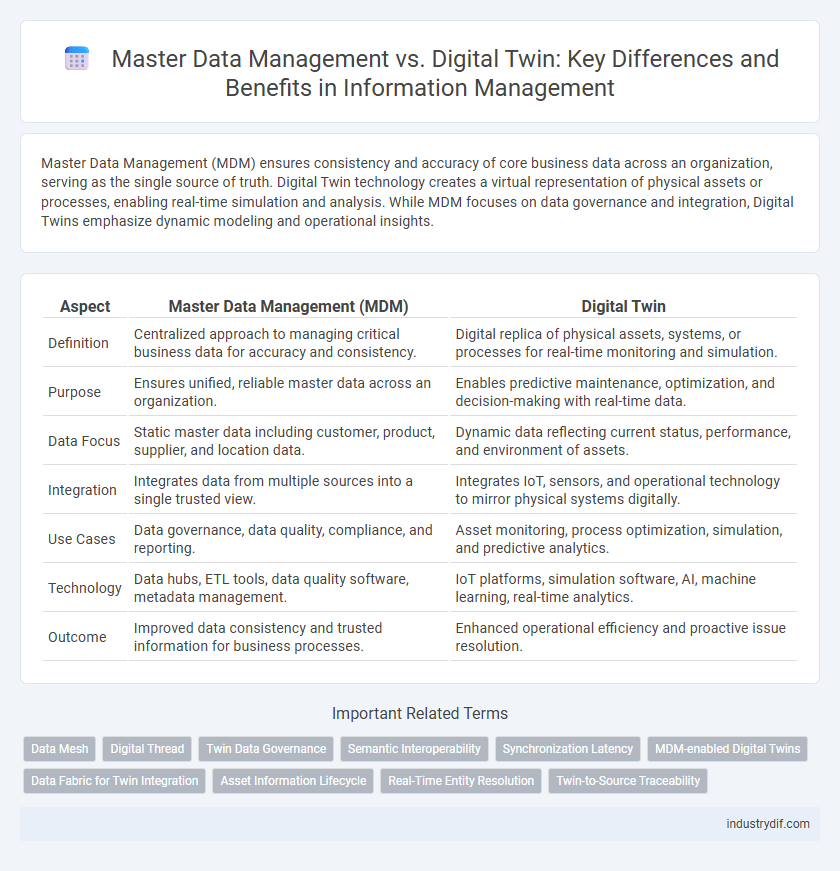

| Aspect | Master Data Management (MDM) | Digital Twin |

|---|---|---|

| Definition | Centralized approach to managing critical business data for accuracy and consistency. | Digital replica of physical assets, systems, or processes for real-time monitoring and simulation. |

| Purpose | Ensures unified, reliable master data across an organization. | Enables predictive maintenance, optimization, and decision-making with real-time data. |

| Data Focus | Static master data including customer, product, supplier, and location data. | Dynamic data reflecting current status, performance, and environment of assets. |

| Integration | Integrates data from multiple sources into a single trusted view. | Integrates IoT, sensors, and operational technology to mirror physical systems digitally. |

| Use Cases | Data governance, data quality, compliance, and reporting. | Asset monitoring, process optimization, simulation, and predictive analytics. |

| Technology | Data hubs, ETL tools, data quality software, metadata management. | IoT platforms, simulation software, AI, machine learning, real-time analytics. |

| Outcome | Improved data consistency and trusted information for business processes. | Enhanced operational efficiency and proactive issue resolution. |

Understanding Master Data Management (MDM)

Master Data Management (MDM) involves the centralized governance and consolidation of critical business data to ensure accuracy, consistency, and accountability across an organization's systems. It enables seamless integration and synchronization of key entities such as customers, products, employees, and suppliers, forming a single source of truth for decision-making and operational efficiency. Understanding MDM's role is essential in differentiating it from Digital Twins, which simulate real-time physical assets or processes rather than managing core data.

Defining Digital Twin Technology

Digital Twin technology creates virtual replicas of physical assets, processes, or systems, enabling real-time monitoring, simulation, and analysis. This digital model integrates sensor data, historical information, and algorithms to optimize performance and predict potential failures. Unlike Master Data Management, which centralizes and governs enterprise data, Digital Twins focus on accurate, dynamic representations for operational insights and decision-making.

Core Components of Master Data Management

Master Data Management (MDM) centers on core components such as data governance, data quality management, and metadata management to ensure consistent and accurate master data across an organization. These components enable unified data integration, harmonization, and synchronization, contrasting with Digital Twin technology, which focuses on real-time simulation and operational insights of physical assets. Effective MDM frameworks rely on robust data stewardship and master data modeling to support business decision-making and digital transformation initiatives.

Key Elements of Digital Twins

Digital Twins integrate real-time data, advanced analytics, and IoT connectivity to create dynamic virtual replicas of physical assets, enabling precise monitoring and predictive maintenance. Key elements include data synchronization from multiple sources, simulation models for scenario analysis, and seamless interaction between the digital and physical environments. Unlike Master Data Management, which consolidates static data for consistency, Digital Twins emphasize continuous data flow and real-time operational insights.

Applications of MDM in Industry

Master Data Management (MDM) is critical in industries for ensuring accurate, consistent, and integrated data across enterprise systems, enhancing operational efficiency and decision-making. MDM applications include customer data integration, product information management, and supplier data synchronization, which streamline processes and improve compliance. Compared to Digital Twin technology, which focuses on virtual replicas of physical assets for real-time monitoring, MDM serves as the foundation for data governance and unified master records essential for enterprise-wide analytics and reporting.

Digital Twin Use Cases Across Sectors

Digital Twin technology enables real-time simulation and monitoring across industries including manufacturing, healthcare, and smart cities, enhancing operational efficiency and predictive maintenance. In manufacturing, Digital Twins optimize production lines by simulating processes and detecting anomalies before they impact output. Smart cities leverage Digital Twins to model infrastructure, improve energy management, and support urban planning decisions based on dynamic data analysis.

Comparative Benefits: MDM vs Digital Twin

Master Data Management (MDM) ensures data consistency and accuracy across an organization by centralizing critical business information such as customer, product, and supplier data, facilitating improved decision-making and regulatory compliance. Digital Twin technology creates dynamic, real-time virtual models of physical assets or processes, enabling predictive maintenance, operational optimization, and enhanced simulation capabilities. While MDM optimizes data governance and integration for enterprise-wide use, Digital Twins focus on real-time insights and scenario analysis, offering complementary benefits in managing organizational knowledge and operational efficiency.

Integration Challenges Between MDM and Digital Twin

Integration challenges between Master Data Management (MDM) and Digital Twin platforms primarily stem from discrepancies in data models, inconsistent data synchronization, and real-time data processing demands. Ensuring seamless interoperability requires resolving semantic mismatches between MDM's structured, authoritative datasets and Digital Twin's dynamic, sensor-derived data streams. Effective integration strategies focus on implementing unified data standards, robust API frameworks, and scalable middleware solutions to bridge data silos and enable accurate, timely digital representations.

Data Governance in MDM and Digital Twin Environments

Master Data Management (MDM) emphasizes stringent data governance frameworks to ensure consistent, accurate, and secure master data across enterprise applications, enhancing data quality and compliance. Digital Twin environments rely on real-time data integration and governance to maintain synchronized, validated virtual models that reflect physical assets' current states, supporting predictive maintenance and operational efficiency. Effective data governance in both MDM and Digital Twin setups is critical for reliable decision-making and regulatory adherence.

Future Trends: Convergence of MDM and Digital Twins

Future trends indicate a growing convergence between Master Data Management (MDM) and Digital Twin technologies, enabling organizations to create unified, real-time digital representations of assets and processes. Integrating MDM's structured data governance with Digital Twins' dynamic simulation capabilities enhances predictive analytics, operational efficiency, and decision-making accuracy. This synergy supports smarter, data-driven strategies in industries such as manufacturing, healthcare, and smart cities, driving innovation through comprehensive and consistent data ecosystems.

Related Important Terms

Data Mesh

Master Data Management (MDM) centralizes and standardizes critical business data to ensure consistency, while Digital Twin technology creates real-time virtual models of physical assets for simulation and analysis. Data Mesh complements these approaches by decentralizing data ownership through domain-oriented platforms, enabling scalable and flexible data sharing across the enterprise.

Digital Thread

Digital Thread integrates data across a product's lifecycle, connecting design, manufacturing, and performance information to enable real-time insights and traceability. Unlike traditional Master Data Management, which consolidates static data sources, Digital Thread emphasizes continuous data flow and interoperability to enhance decision-making and operational efficiency.

Twin Data Governance

Master Data Management (MDM) ensures accuracy, consistency, and control of core enterprise data, while Digital Twin governance focuses on managing real-time, dynamic data streams to accurately mirror physical asset states. Effective Twin Data Governance integrates MDM principles to maintain high-quality, synchronized data crucial for predictive analytics and operational decision-making.

Semantic Interoperability

Master Data Management (MDM) ensures consistent and accurate core business data across systems, while Digital Twin technology creates a dynamic, real-time virtual replica of physical assets and processes; semantic interoperability bridges these by enabling shared understanding and precise data exchange through standardized ontologies and metadata frameworks. Achieving semantic interoperability between MDM and Digital Twin systems enhances decision-making and operational efficiency by harmonizing master data attributes with digital twin models for seamless integration and context-aware analytics.

Synchronization Latency

Master Data Management (MDM) typically experiences synchronization latency measured in minutes or hours as it consolidates and cleanses data from multiple sources to ensure accuracy and consistency. Digital Twin environments demand near real-time synchronization latency ranging from milliseconds to seconds to reflect dynamic physical asset changes and enable precise simulations.

MDM-enabled Digital Twins

Master Data Management (MDM) provides a unified, accurate, and consistent data foundation essential for creating reliable Digital Twins, enabling real-time synchronization between physical assets and their virtual counterparts. MDM-enabled Digital Twins leverage standardized master data to enhance predictive analytics, optimize asset performance, and improve operational decision-making in complex systems.

Data Fabric for Twin Integration

Master Data Management (MDM) ensures consistent, authoritative data across an organization, while Digital Twins simulate real-world entities through dynamic digital models. Integrating these with a Data Fabric architecture enhances seamless data flow and real-time synchronization, enabling efficient Twin integration and improved decision-making.

Asset Information Lifecycle

Master Data Management (MDM) centralizes and standardizes asset information to ensure accuracy and consistency throughout the asset information lifecycle. Digital Twin technology creates dynamic, real-time virtual representations of physical assets, enabling continuous monitoring, simulation, and optimization across the asset lifecycle stages.

Real-Time Entity Resolution

Master Data Management (MDM) centralizes and cleanses enterprise data, providing consistent and accurate master records, while Digital Twins create virtual replicas of physical entities to simulate real-time conditions and operations. Real-time entity resolution in MDM ensures unique identification across systems, enabling Digital Twins to leverage accurate, up-to-date data streams for dynamic modeling and predictive analytics.

Twin-to-Source Traceability

Master Data Management (MDM) ensures data consistency and integrity across enterprise systems, while Digital Twin leverages real-time data to create dynamic virtual replicas of physical assets. Twin-to-Source traceability links digital twin data back to the original master data sources, enabling accurate synchronization, impact analysis, and enhanced decision-making across product lifecycles.

Master Data Management vs Digital Twin Infographic

industrydif.com

industrydif.com