Industrial logistics hubs prioritize efficient transportation networks and large-scale warehousing to support supply chain operations, often located on city outskirts for space and accessibility. Urban infill focuses on repurposing underutilized city spaces to create mixed-use developments that reduce commute times and promote sustainable growth. Balancing these approaches is essential for optimizing real estate strategies that meet both distribution efficiency and urban density demands.

Table of Comparison

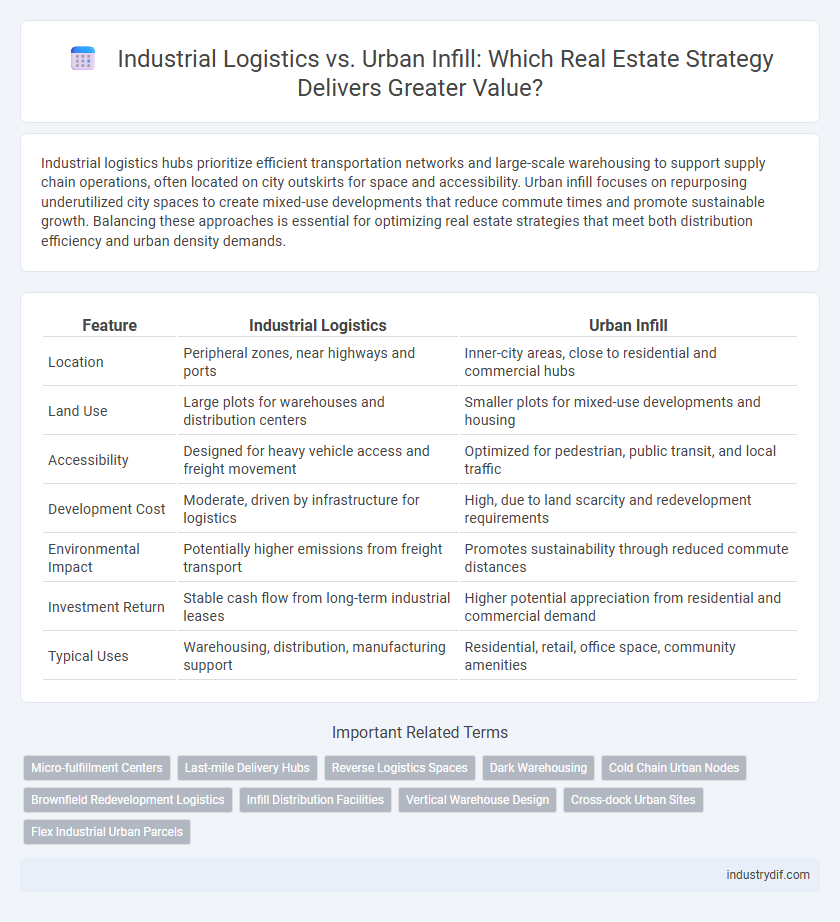

| Feature | Industrial Logistics | Urban Infill |

|---|---|---|

| Location | Peripheral zones, near highways and ports | Inner-city areas, close to residential and commercial hubs |

| Land Use | Large plots for warehouses and distribution centers | Smaller plots for mixed-use developments and housing |

| Accessibility | Designed for heavy vehicle access and freight movement | Optimized for pedestrian, public transit, and local traffic |

| Development Cost | Moderate, driven by infrastructure for logistics | High, due to land scarcity and redevelopment requirements |

| Environmental Impact | Potentially higher emissions from freight transport | Promotes sustainability through reduced commute distances |

| Investment Return | Stable cash flow from long-term industrial leases | Higher potential appreciation from residential and commercial demand |

| Typical Uses | Warehousing, distribution, manufacturing support | Residential, retail, office space, community amenities |

Defining Industrial Logistics and Urban Infill

Industrial logistics encompasses large-scale facilities designed for warehousing, distribution, and transportation hubs that support supply chain efficiency across regional markets. Urban infill refers to the development of vacant or underused parcels within existing urban areas, aiming to optimize land use and enhance community connectivity. Both concepts address different real estate needs: industrial logistics prioritizes operational scale and accessibility, while urban infill focuses on sustainable growth and urban density.

Key Differences Between Industrial Logistics and Urban Infill

Industrial logistics centers prioritize large-scale distribution hubs with extensive warehouse space, optimized for freight accessibility and transportation efficiency. Urban infill developments focus on revitalizing underutilized urban parcels, promoting mixed-use spaces that integrate residential, retail, and commercial functions. Key differences include scale, location priorities, and the balance between transportation infrastructure and community integration.

Site Selection Criteria: Logistics vs Urban Infill

Site selection criteria for industrial logistics prioritize proximity to major transportation hubs, such as highways, railroads, and ports, to ensure efficient goods movement and supply chain integration. Urban infill sites emphasize accessibility to dense population centers, existing infrastructure, and walkability to support mixed-use developments and reduce urban sprawl. Balancing factors like land cost, zoning regulations, and environmental impact is crucial for optimizing site selection in both industrial logistics and urban infill projects.

Cost Considerations in Industrial Logistics and Urban Infill

Industrial logistics developments typically incur higher infrastructure and transportation costs due to the need for extensive road access, large-scale loading docks, and warehousing facilities. Urban infill projects often face elevated land acquisition and regulatory compliance expenses, driven by limited space and stricter zoning regulations in densely populated areas. Balancing these cost factors is critical for maximizing return on investment and operational efficiency in real estate planning.

Location Strategies: Periphery vs Urban Core

Industrial logistics facilities often favor periphery locations due to lower land costs, larger available parcels, and proximity to highways and distribution networks, enabling efficient freight movement. Urban infill developments prioritize urban core sites to capitalize on existing infrastructure, closer access to labor markets, and reduced last-mile delivery distances, supporting sustainability and market responsiveness. Location strategies balance operational efficiency with market demands, where industrial logistics optimize for scale and accessibility, while urban infill targets density and connectivity.

Impact on Supply Chain Efficiency

Industrial logistics centers strategically located near major transportation hubs enhance supply chain efficiency by reducing transit times and lowering transportation costs. Urban infill developments, while promoting sustainable land use and reducing last-mile delivery distances, often face constraints such as limited space and higher operational costs, which can impact supply chain scalability. Balancing the advantages of centralized industrial logistics with the accessibility of urban infill projects is critical for optimizing overall supply chain performance.

Zoning and Regulatory Challenges

Industrial logistics projects often face complex zoning regulations that restrict land use to specific industrial zones, limiting expansion and increasing compliance costs. Urban infill developments contend with stricter zoning codes aimed at preserving neighborhood character, including height restrictions, density limits, and historic preservation rules. Navigating these regulatory challenges requires strategic planning to balance development goals with local government policies in both industrial and urban contexts.

Sustainability and Environmental Impacts

Industrial logistics hubs prioritize large-scale operations that often require greenfield developments, potentially leading to habitat disruption and increased carbon emissions from transportation. Urban infill, emphasizing redevelopment within existing urban areas, minimizes land consumption and supports sustainable city growth by reducing reliance on long-haul trucking and encouraging the use of public transit and non-motorized transport options. By concentrating on higher density and mixed-use developments, urban infill significantly lowers environmental impacts through decreased energy consumption and improved resource efficiency compared to sprawling industrial logistics centers.

Trends Driving Industrial Logistics and Urban Infill Demand

Rising e-commerce growth and supply chain reshoring are accelerating demand for industrial logistics spaces near urban centers, prompting developers to prioritize last-mile distribution hubs. Urban infill gains momentum as cities focus on reducing commute times and promoting sustainable land use, leading to increased mixed-use developments and adaptive reuse projects. Technologies like automation and data analytics enhance warehouse efficiency, while demographic shifts drive demand for walkable, transit-oriented urban living.

Future Outlook: Industrial Logistics vs Urban Infill

Industrial logistics hubs are projected to expand rapidly due to the growth of e-commerce and demand for efficient supply chains, emphasizing proximity to major transportation networks. Urban infill developments will gain momentum as cities strive to optimize land use, reduce sprawl, and promote sustainable living through mixed-use projects. Future real estate strategies will balance between large-scale industrial properties and high-density urban infill to meet evolving economic and environmental priorities.

Related Important Terms

Micro-fulfillment Centers

Industrial logistics centers are strategically located on city outskirts to facilitate large-scale distribution with ample space for trucks and warehouses, optimizing supply chain efficiency. Urban infill micro-fulfillment centers, however, prioritize proximity to consumers within dense city areas, utilizing smaller footprints and advanced automation to enable rapid delivery and meet increasing same-day e-commerce demand.

Last-mile Delivery Hubs

Last-mile delivery hubs benefit from urban infill locations by reducing transit times and enhancing distribution efficiency in densely populated areas, thereby lowering transportation costs and emissions. Industrial logistics sites, while offering larger storage capacities, often face challenges with accessibility and speed in last-mile delivery compared to compact urban infill hubs optimized for rapid parcel drop-offs.

Reverse Logistics Spaces

Reverse logistics spaces in industrial logistics offer expansive areas designed for efficient return, refurbishment, and redistribution of goods, essential for managing supply chain reversals. Urban infill projects prioritize the adaptive reuse of underutilized plots within city centers, creating compact reverse logistics hubs that reduce transportation costs and environmental impact by leveraging proximity to end consumers.

Dark Warehousing

Dark warehousing, a key component of industrial logistics, enables 24/7 automated storage and distribution without human presence, contrasting with urban infill developments that prioritize mixed-use, walkable spaces to reduce transportation costs and promote sustainability. The growing demand for e-commerce fulfillment drives dark warehousing in suburban industrial parks, while urban infill focuses on maximizing land use efficiency within city limits.

Cold Chain Urban Nodes

Cold chain urban nodes enhance industrial logistics by providing temperature-controlled storage and distribution facilities strategically located within urban infill areas, reducing transit times and preserving product integrity. This integration supports efficient last-mile delivery for perishable goods, meeting the growing demand for fresh products in densely populated cities.

Brownfield Redevelopment Logistics

Brownfield redevelopment logistics transforms underutilized urban industrial sites into efficient supply chain hubs, reducing transportation costs and environmental impact by leveraging existing infrastructure. This approach contrasts with sprawling industrial logistics parks by optimizing land use, supporting sustainable urban growth, and revitalizing communities through strategic urban infill projects.

Infill Distribution Facilities

Infill distribution facilities leverage urban infill locations to optimize last-mile delivery efficiency and reduce transportation costs compared to traditional industrial logistics hubs situated on city outskirts. These strategically placed urban properties offer enhanced connectivity to dense consumer markets, driving demand for smaller-footprint warehouses that support rapid fulfillment and sustainability goals.

Vertical Warehouse Design

Vertical warehouse design maximizes storage capacity within limited urban infill spaces, optimizing land use and reducing transportation costs by situating facilities closer to end-users. Industrial logistics benefits from this approach by enhancing supply chain efficiency and enabling faster distribution compared to traditional sprawling industrial parks.

Cross-dock Urban Sites

Cross-dock urban sites leverage industrial logistics by facilitating rapid transfer of goods between transportation modes in dense city environments, optimizing supply chain efficiency while minimizing last-mile delivery times. These locations prioritize proximity to distribution networks and urban centers, enhancing access to major highways and reducing transportation costs compared to traditional industrial logistics hubs.

Flex Industrial Urban Parcels

Flex industrial urban parcels offer versatile spaces designed to accommodate the evolving needs of e-commerce, last-mile delivery, and light manufacturing within densely populated markets. These strategically located sites maximize urban infill benefits by reducing transportation costs and improving supply chain efficiency compared to traditional industrial logistics parks on city outskirts.

Industrial logistics vs Urban infill Infographic

industrydif.com

industrydif.com