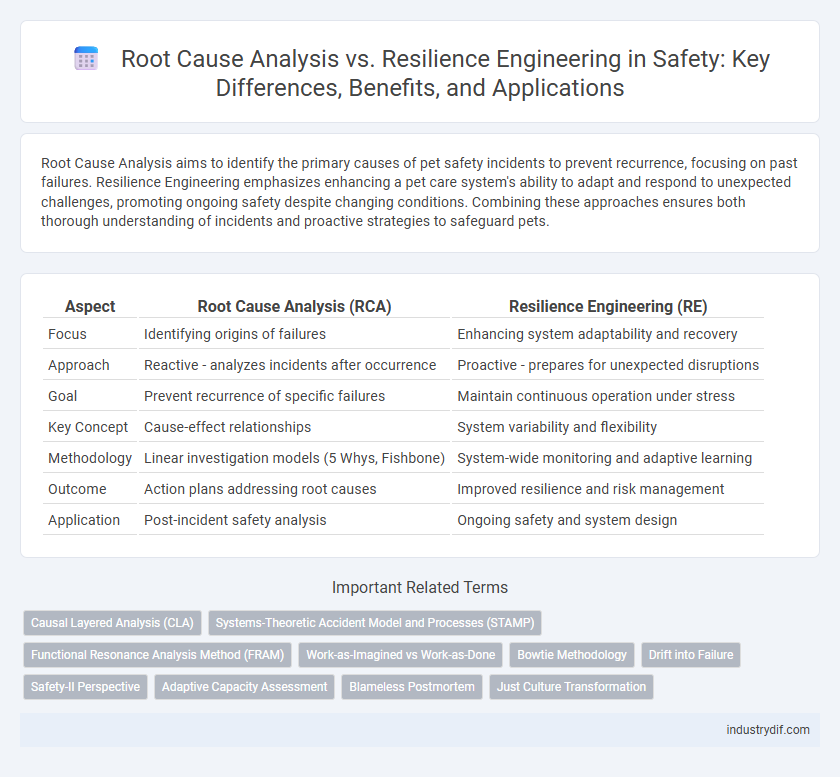

Root Cause Analysis aims to identify the primary causes of pet safety incidents to prevent recurrence, focusing on past failures. Resilience Engineering emphasizes enhancing a pet care system's ability to adapt and respond to unexpected challenges, promoting ongoing safety despite changing conditions. Combining these approaches ensures both thorough understanding of incidents and proactive strategies to safeguard pets.

Table of Comparison

| Aspect | Root Cause Analysis (RCA) | Resilience Engineering (RE) |

|---|---|---|

| Focus | Identifying origins of failures | Enhancing system adaptability and recovery |

| Approach | Reactive - analyzes incidents after occurrence | Proactive - prepares for unexpected disruptions |

| Goal | Prevent recurrence of specific failures | Maintain continuous operation under stress |

| Key Concept | Cause-effect relationships | System variability and flexibility |

| Methodology | Linear investigation models (5 Whys, Fishbone) | System-wide monitoring and adaptive learning |

| Outcome | Action plans addressing root causes | Improved resilience and risk management |

| Application | Post-incident safety analysis | Ongoing safety and system design |

Introduction to Root Cause Analysis and Resilience Engineering

Root Cause Analysis (RCA) systematically identifies underlying causes of safety incidents to prevent recurrence by analyzing failure points and contributing factors. Resilience Engineering emphasizes the capacity of systems to anticipate, absorb, recover, and adapt to unexpected disruptions, prioritizing flexibility and proactive safety measures. Both approaches enhance safety management, with RCA focusing on retrospective problem-solving and Resilience Engineering promoting dynamic system robustness.

Defining Root Cause Analysis in Safety Management

Root Cause Analysis (RCA) in safety management systematically identifies underlying causes of incidents to prevent recurrence and enhance workplace safety. It involves data collection, causal factor charting, and pinpointing systemic failures rather than symptomatic issues. RCA emphasizes corrective actions targeting organizational processes, contributing to sustained risk reduction and compliance with safety regulations.

Understanding Resilience Engineering Principles

Resilience Engineering emphasizes the ability of systems to adapt and recover from unexpected disturbances by focusing on flexibility, learning, and anticipation rather than solely identifying failures. Unlike Root Cause Analysis which seeks to pinpoint and eliminate specific causes of failure, Resilience Engineering promotes continuous monitoring and proactive adjustments to maintain system functionality under varying conditions. Key principles include system adaptability, capacity for real-time response, and fostering organizational learning to enhance overall safety and reliability.

Historical Evolution of Safety Approaches

Root Cause Analysis (RCA) emerged in the mid-20th century as a systematic method to identify underlying causes of accidents by tracing faults in machinery, processes, or human error. Resilience Engineering evolved in the early 2000s, shifting focus from failure investigation to enhancing system adaptability and proactive risk management in complex socio-technical environments. This evolution reflects a transition from reactive safety measures toward designing systems capable of anticipating and absorbing disturbances before failures occur.

Key Differences: Root Cause Analysis vs Resilience Engineering

Root Cause Analysis (RCA) focuses on identifying and eliminating specific causes of failures to prevent recurrence, primarily by analyzing past incidents and errors. Resilience Engineering emphasizes enhancing a system's ability to adapt, respond, and recover from unexpected challenges, prioritizing ongoing adaptability over pinpointing single failures. RCA is reactive and corrective, while Resilience Engineering is proactive and adaptive, targeting system robustness rather than isolated fault elimination.

Strengths and Limitations of Root Cause Analysis

Root Cause Analysis (RCA) excels at identifying specific failure points within safety systems by systematically investigating incidents to prevent recurrence. Its strength lies in providing clear, actionable insights from past events, but it often overlooks complex system interactions and emergent risks inherent in dynamic work environments. Limitations include a reactive approach and difficulty addressing adaptive or latent hazards, which resilience engineering aims to complement through proactive capacity building and system adaptability.

Advantages and Challenges of Resilience Engineering

Resilience Engineering emphasizes the ability of systems to adapt and recover from unexpected disruptions, offering advantages such as proactive risk management and enhanced organizational flexibility. It challenges traditional Root Cause Analysis by focusing on everyday performance variability rather than solely on failure events, enabling continuous improvement in complex environments. However, implementing Resilience Engineering requires cultural shifts, significant training, and integration into existing safety protocols, which can pose practical and resource-intensive challenges for organizations.

Practical Applications in Industrial Safety

Root Cause Analysis (RCA) focuses on identifying and eliminating the fundamental causes of industrial accidents to prevent recurrence, often through investigative methods post-incident. Resilience Engineering emphasizes enhancing system adaptability and the capacity to anticipate, absorb, and recover from unexpected disruptions in real time. Integrating RCA with Resilience Engineering enables industries to both address specific failure points and build dynamic safety capabilities that improve overall operational reliability.

Integrating Both Approaches for Optimal Safety

Integrating Root Cause Analysis (RCA) with Resilience Engineering enhances safety by addressing both failure origins and system adaptability under unexpected conditions. RCA systematically identifies and eliminates specific faults, while Resilience Engineering focuses on maintaining operations through flexibility and learning from variability. Combining these approaches creates a comprehensive safety framework that reduces risks and strengthens organizational capacity to respond to evolving hazards.

Future Trends in Safety: From RCA to Resilience Engineering

Future trends in safety emphasize a shift from traditional Root Cause Analysis (RCA), which concentrates on identifying underlying causes of incidents, to Resilience Engineering, which prioritizes enhancing system adaptability and proactive risk management. This evolution integrates advanced data analytics, real-time monitoring, and human factors to anticipate failures before they occur and maintain continuous safe operations. Organizations adopting resilience-based frameworks demonstrate improved capacity to recover from disruptions and sustain performance in complex, dynamic environments.

Related Important Terms

Causal Layered Analysis (CLA)

Causal Layered Analysis (CLA) enhances root cause analysis by exploring multiple layers of causation, including litany, systemic causes, worldview, and myth/metaphor, thereby providing a deeper understanding of safety incidents beyond immediate technical failures. In contrast, resilience engineering focuses on system adaptability and recovery, using CLA to identify underlying cultural and cognitive factors that support robust safety performance.

Systems-Theoretic Accident Model and Processes (STAMP)

Root Cause Analysis (RCA) primarily identifies failures in components or human errors, while Resilience Engineering, particularly through the Systems-Theoretic Accident Model and Processes (STAMP), emphasizes understanding complex system interactions and control structures to prevent accidents. STAMP frames safety as a control problem, focusing on enforcing constraints across socio-technical systems rather than solely addressing isolated root causes.

Functional Resonance Analysis Method (FRAM)

Root Cause Analysis (RCA) focuses on identifying specific failures in safety incidents, while Resilience Engineering, particularly through the Functional Resonance Analysis Method (FRAM), emphasizes understanding variability in complex systems to enhance adaptability and mitigate risks. FRAM models the interactions and functions within a system, enabling organizations to anticipate unexpected outcomes and improve safety performance beyond linear cause-effect relationships.

Work-as-Imagined vs Work-as-Done

Root Cause Analysis often emphasizes Work-as-Imagined by identifying failures based on prescribed procedures and expected outcomes, whereas Resilience Engineering focuses on Work-as-Done, recognizing adaptive behaviors and real-time adjustments frontline workers employ to ensure safety. Understanding the divergence between these perspectives is critical for developing effective safety interventions that reflect actual operational complexities.

Bowtie Methodology

Root Cause Analysis focuses on identifying and eliminating the underlying causes of safety incidents, while Resilience Engineering emphasizes enhancing system adaptability and robustness to prevent failures. The Bowtie Methodology integrates both approaches by visually mapping hazard pathways, barriers, and controls, enabling organizations to proactively manage risks and strengthen safety resilience.

Drift into Failure

Root Cause Analysis focuses on identifying specific triggers that cause accidents, whereas Resilience Engineering addresses the ongoing Drift into Failure by enhancing system adaptability and anticipating deviations before they lead to harm. Emphasizing resilience helps organizations manage complex safety challenges by continuously monitoring operational variability and reinforcing protective mechanisms to prevent failure escalation.

Safety-II Perspective

Root Cause Analysis often focuses on identifying and eliminating failures after incidents, whereas Resilience Engineering emphasizes understanding everyday successful performance to enhance system adaptability and safety. The Safety-II perspective promotes proactive strategies that build resilient systems capable of anticipating, monitoring, responding to, and learning from unexpected challenges.

Adaptive Capacity Assessment

Root Cause Analysis (RCA) primarily investigates specific failures to identify underlying causes, often neglecting the dynamic and complex interactions within systems, whereas Resilience Engineering emphasizes Adaptive Capacity Assessment to evaluate how effectively organizations anticipate, respond to, and recover from disruptions. Adaptive Capacity Assessment in Resilience Engineering measures an organization's ability to learn, adapt operational processes, and maintain safety under varying conditions, promoting proactive risk management beyond fault identification.

Blameless Postmortem

Root Cause Analysis aims to identify a single failure cause often leading to blame, whereas Resilience Engineering promotes a blameless postmortem culture emphasizing system adaptability and learning from unexpected failures. Blameless postmortems improve safety by fostering open communication, reducing fear of punishment, and enabling continuous system improvement.

Just Culture Transformation

Root Cause Analysis emphasizes identifying and mitigating specific failures to prevent recurrence, while Resilience Engineering focuses on enhancing system adaptability and learning to manage unexpected challenges effectively. Just Culture Transformation integrates these approaches by fostering an environment where accountability and continuous improvement coexist, promoting safety through transparent error reporting and systemic resilience.

Root Cause Analysis vs Resilience Engineering Infographic

industrydif.com

industrydif.com